Automotive electric ascending and descending table

A lifting table, electric technology, applied in the direction of vehicle parts, special position of the vehicle, vehicle interior lighting device, etc., can solve the problem of limited bearing capacity of the cylinder, poor table stability, uncontrollable lifting height and speed of the cylinder, etc., to ensure the bearing capacity Stability, high stability, and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

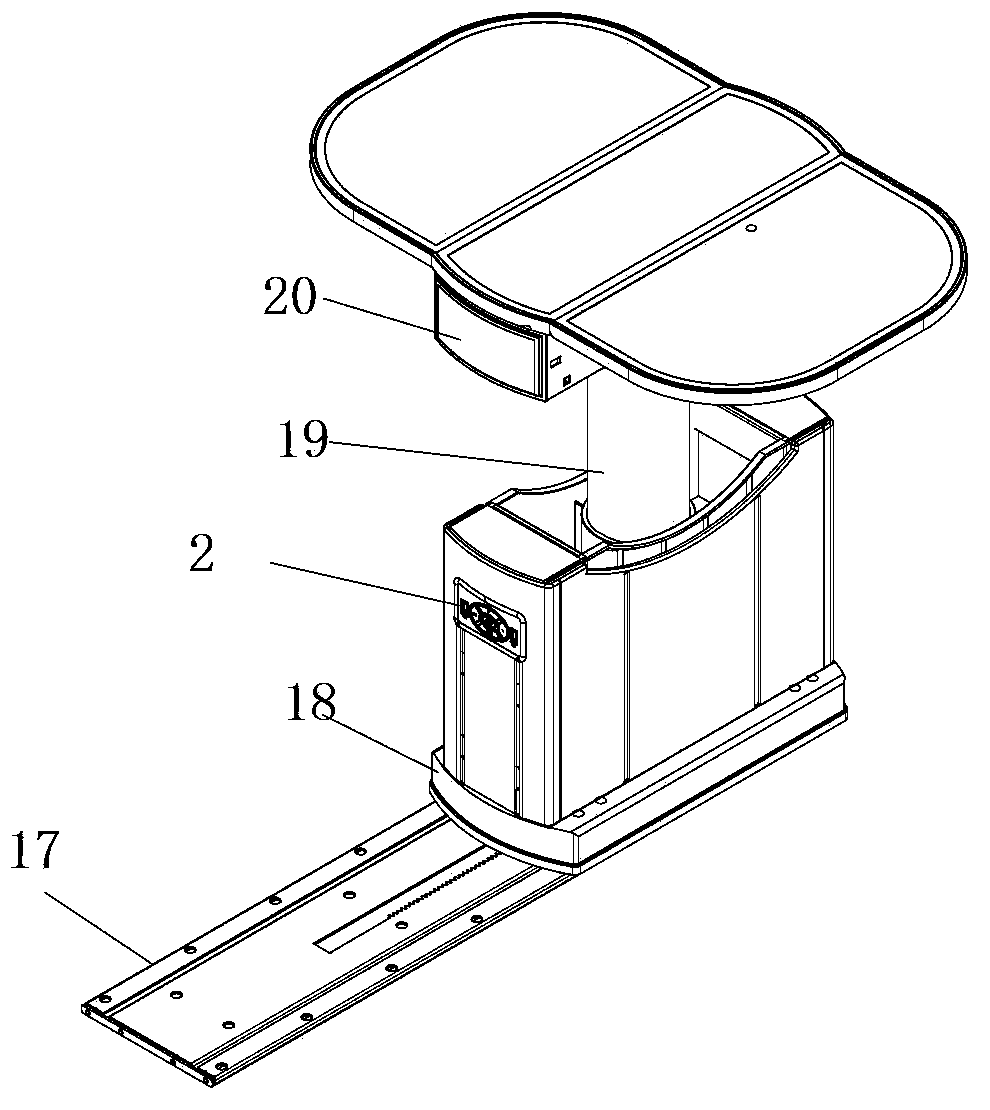

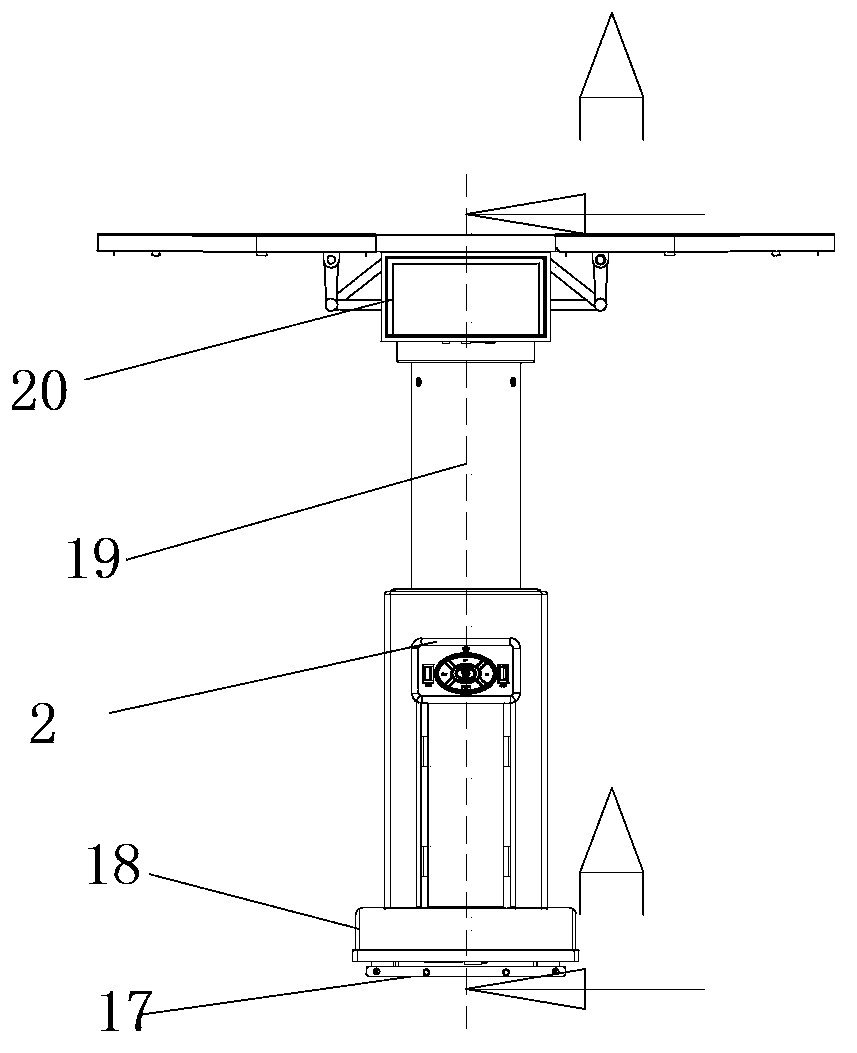

[0026] The car electric lifting table includes a guide rail 17 connected to the car, and a table body that can slide is connected to the guide rail 17. It is characterized in that: the table body includes a base 18 connected to the guide rail, and the base 18 is connected with A guide post 19 that can be lifted. The guide post 19 includes an inner guide post that is fixedly connected to the base, and an outer guide post that is installed outside the inner guide post and can be lifted up and down. The top of the outer guide post is connected to a workbench 20. The base 18 is provided with a power device 21, the power device 21 is connected with a transmission mechanism 22 that drives the guide column up and down, and also includes a control device 2 arranged inside the lifting table, the control device 2 and the power device 21 Connect by wire. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com