Six-degree-of-freedom humanoid robot arm

A technology of humanoid robot and degree of freedom, which is applied in the field of robot arm, can solve the problems of bloated joint structure, heavy weight, and small load-bearing ratio of the robot arm, and achieve the effect of simple shoulder joint rotation structure, simple structure, and compact appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

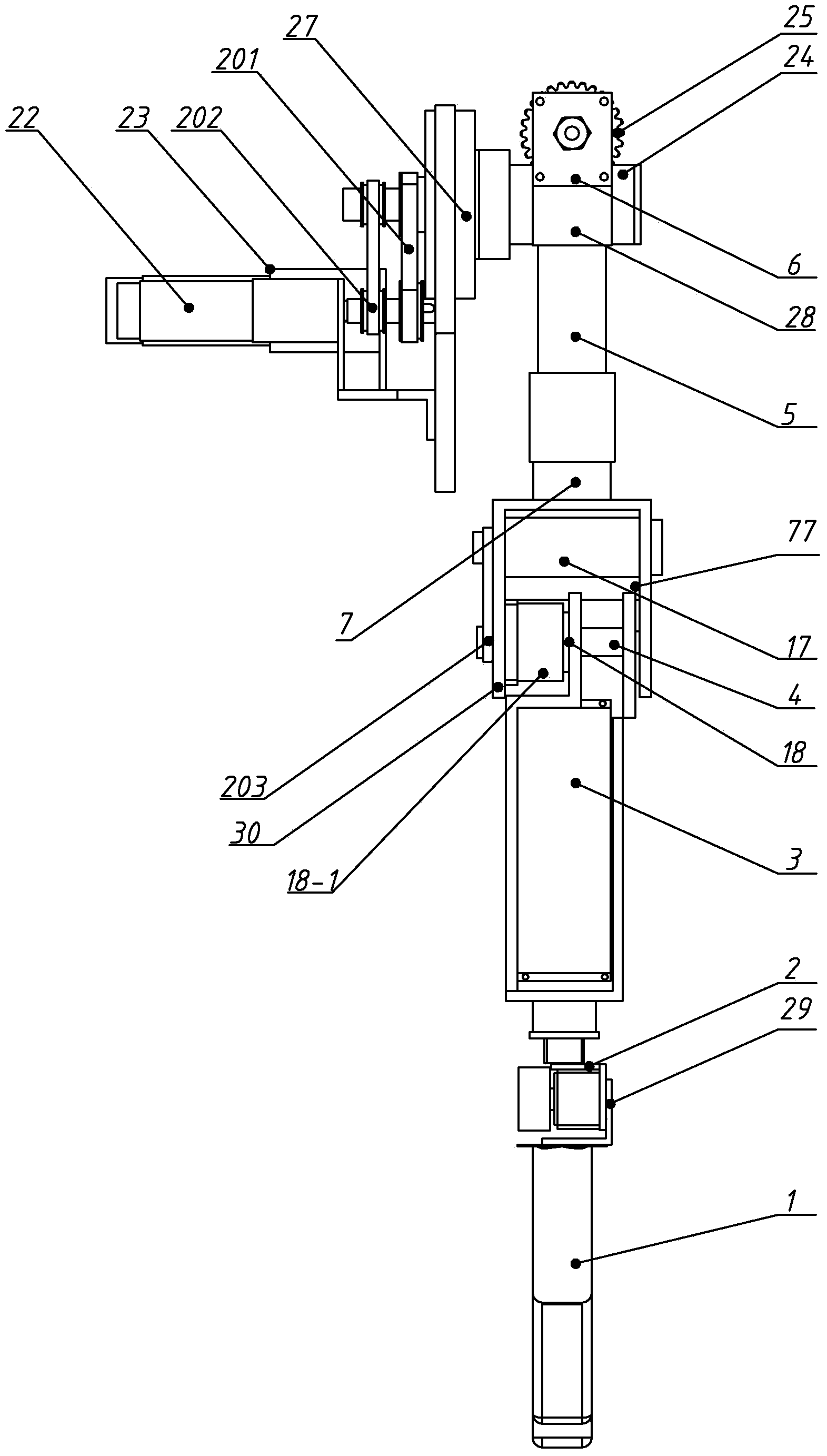

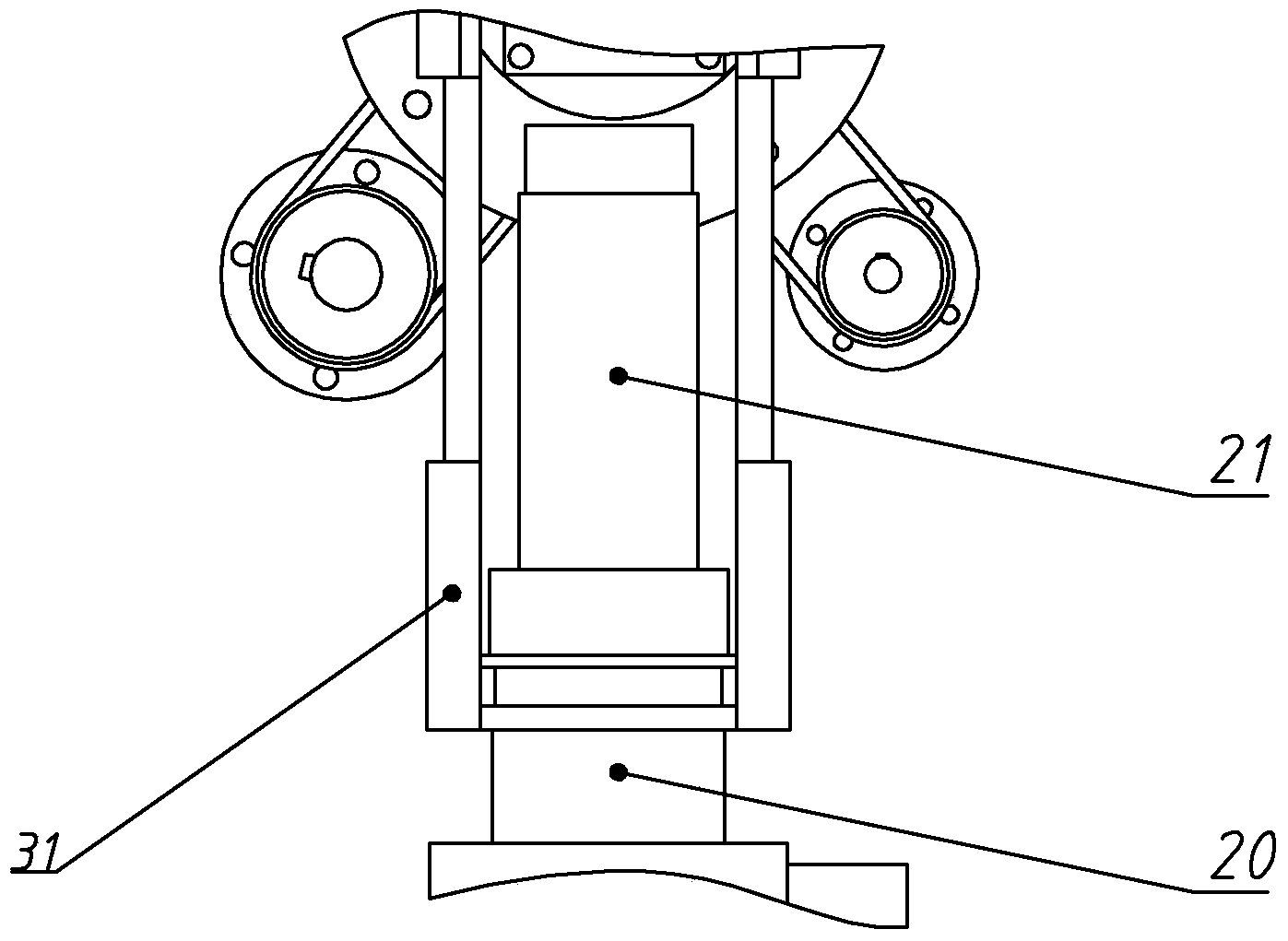

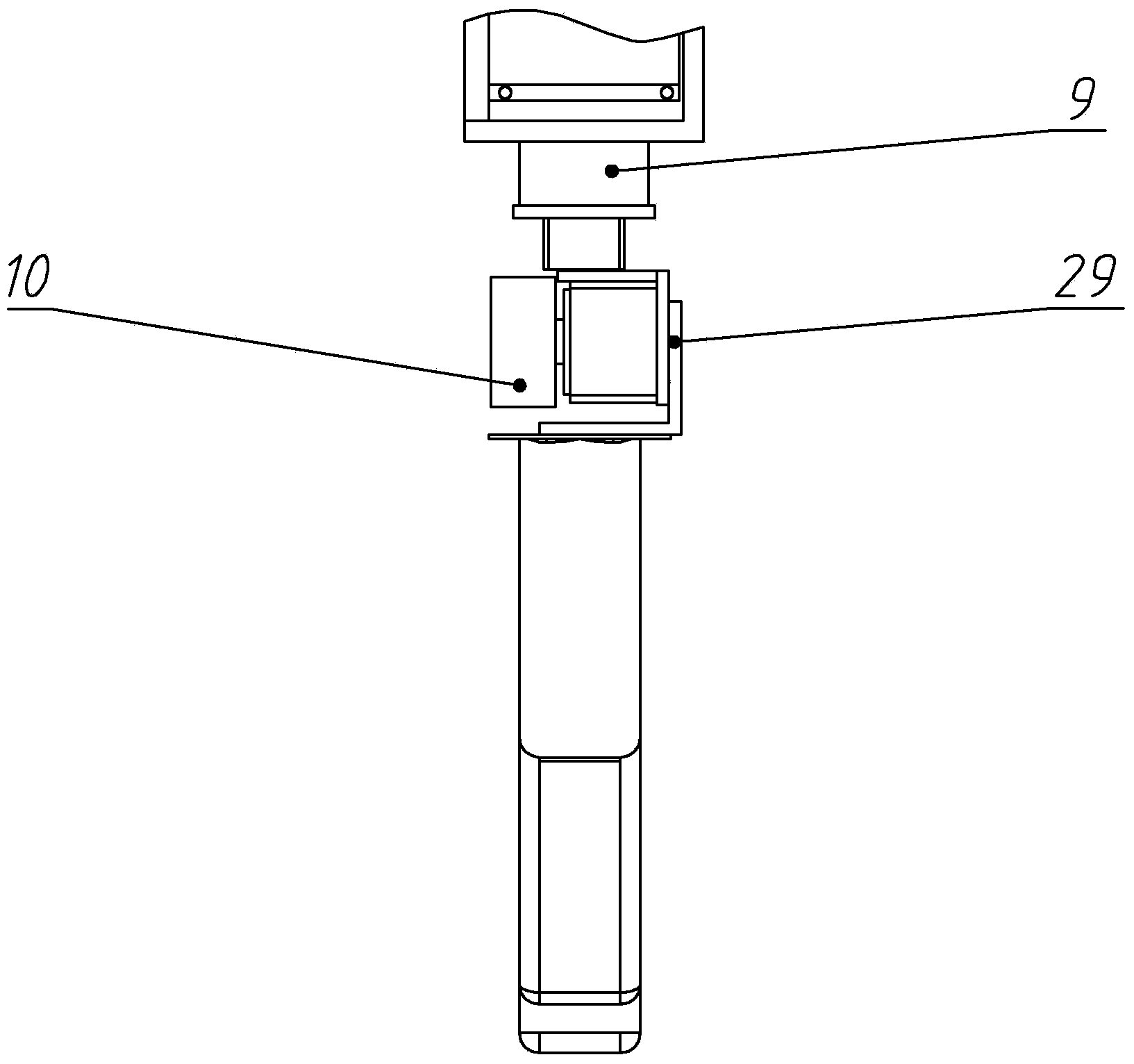

[0020] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, this embodiment includes claw 1, wrist joint 2, forearm 3, elbow pendulum joint 18, elbow joint 77, big arm 5 and shoulder joint 6, shoulder joint 6, big arm 5, elbow joint 77, Forearm 3, wrist joint 2 and hand claw 1 are arranged in sequence from top to bottom,

[0021] Described shoulder joint 6 comprises swing arm servo motor 22, swing arm servo motor 23, rotating conveyor belt 201, swing arm conveyor belt 202, shoulder swing support 27, worm gear 25, worm screw 24 and shoulder joint support 28, shoulder swing support 27 and Shoulder joint support 28 is fixedly arranged successively from left to right, and rotating conveyor belt 201 and swing arm conveyor belt 202 are arranged on shoulder lifting and the left side of rotating support 27, and worm gear 25 and worm screw 24 are arranged on shoulder joint support 28, and worm gear 25 and The worm screw 24 is engaged with each other, ...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 This embodiment will be described. In this embodiment, the servo motor 17 of the elbow swing joint 4 is horizontally arranged in the elbow joint housing 30 and connected to the conveyor belt 203 . Such setting saves space and reduces the driving load on the shoulder. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 The present embodiment will be described. Both the wrist joint swing motor 10 and the wrist joint rotation motor 9 in this embodiment are disk motors. With such arrangement, the volume is small, the space is saved and the terminal payload is improved. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com