Cross slip ring storage rack

A cross-slip ring and storage rack technology, which is applied to tool storage devices, manufacturing tools, etc., can solve problems such as damage and bumps on the machining surfaces of cross-slip ring parts, and achieve the effects of improving the rate of qualified products, preventing mutual bumps, and facilitating statistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

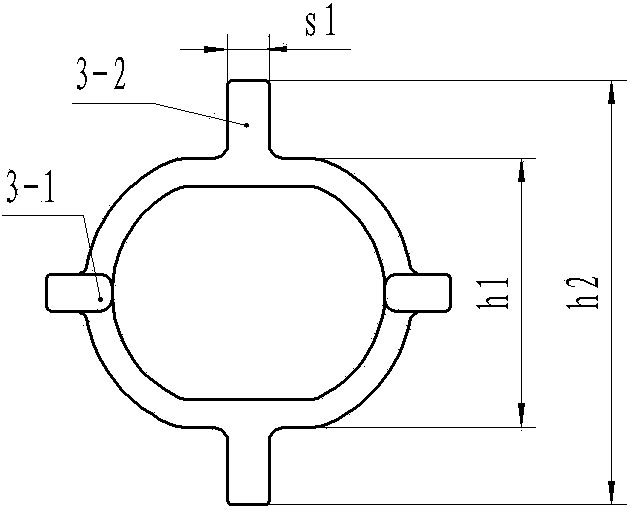

[0016] Such as figure 1 The shown Oldham slip ring has an oval ring and a pair of first protrusions 3-1 and a pair of second protrusions 3-2 protruding outward from the outer edge of the ring, the first protrusion 3- 1 is arranged on the long axis of the ring, and the second protrusion 3-2 is arranged on the short axis of the ring; the width s1 of the second protrusion 3-2 of the Oldham slip ring in this embodiment is 9 mm, The minimum width h1 of the short axis of the cross slip ring is 58 mm, and the maximum width h2 of the short axis of the ring is 91.5 mm.

[0017] Such as Figure 2 to Figure 5 The shown Oldham slip ring storage rack includes a frame body 1 for storing Oldham slip rings. In this embodiment, three storage units are provided in the frame body 2, and each storage unit has two opposite storage racks 2. The storage rack 2 It is welded by a plurality of steel wires with a diameter of 6mm; the distance between two storage racks 2 is at least greater than the mi...

Embodiment 2

[0020] Such as Figure 2 to Figure 5 The shown Oldham slip ring storage rack includes a frame body 1 for storing Oldham slip rings. In this embodiment, three storage units are provided in the frame body 2, and each storage unit has two opposite storage racks 2. The storage rack 2 It is welded by a plurality of steel wires with a diameter of 6mm; the distance between two storage racks 2 is at least greater than the minimum width of one of the major or minor axes of the ring part of the cross slip ring and at least smaller than that of the cross slip ring in the same direction. The maximum width of the ring part of the ring; the distance between the distance between the two storage racks 2 of the present embodiment is designed with the width of the short axis of the ring part of the Oldham slip ring, and the distance h between the two storage racks 2 is 66mm; the width of the positioning groove 2-1 is the width of the projection of the major axis or the minor axis of the ring pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com