Novel electric welding machine

An electric welding machine, a new technology, applied in the direction of arc welding equipment, welding equipment, welding equipment, etc., can solve the problems of poor heat dissipation and waste of electric energy, and achieve the effect of simple structure, convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

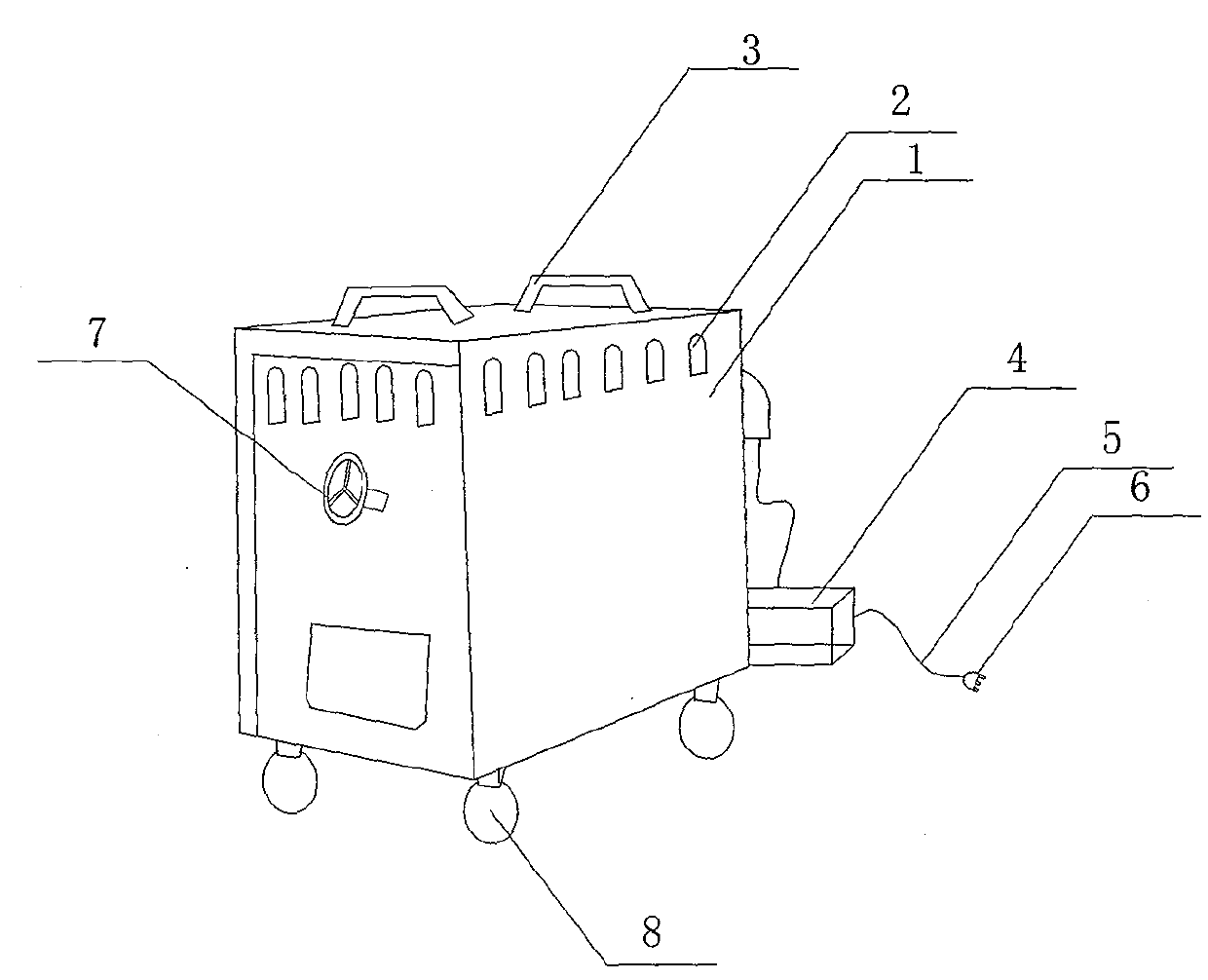

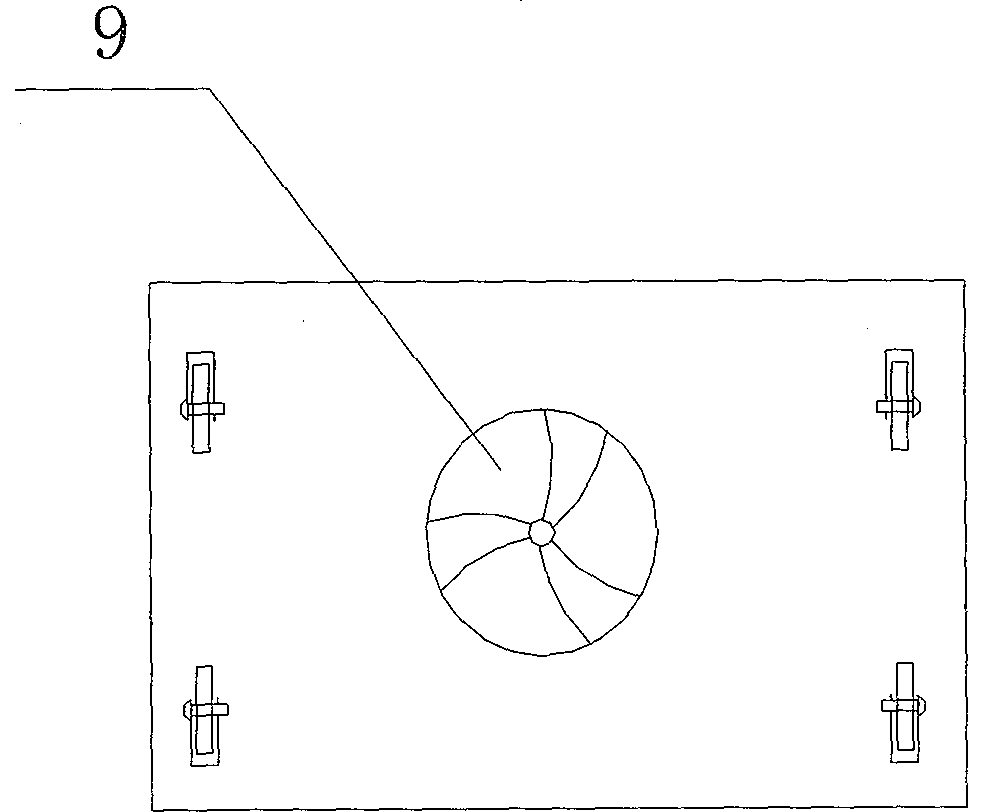

[0009] refer to Figure 1-2 , the specific embodiment adopts the following technical scheme: it comprises electric welding machine casing 1, cooling hole 2, handle 3, power saver protector 4, wire 5, plug 6, winding turntable 7, roller 8 and cooling fan 9, electric welding machine A handle 3 is arranged on the top of the casing 1, and several cooling holes 2 are evenly arranged on the outer wall around the upper end of the welding machine casing 1, and a power-saving protector 4 is connected to one side of the welding machine casing 1, and the power-saving protector 4 The wire 5 is connected to the plug 6, and the outer wall of the electric welding machine casing 1 is fixedly provided with a winding turntable 7, the bottom four feet of the electric welding machine casing 1 are provided with rollers 8, and the middle part of the bottom plate of the electric welding machine casing 1 is provided with A through hole, a cooling fan 9 is fixedly arranged below the through hole.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com