Novel electric feed mixing blender

A mixer and motor technology, which is applied in mixers, mixer accessories, feed and other directions, can solve the problems of high energy consumption, slow mixing speed, and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

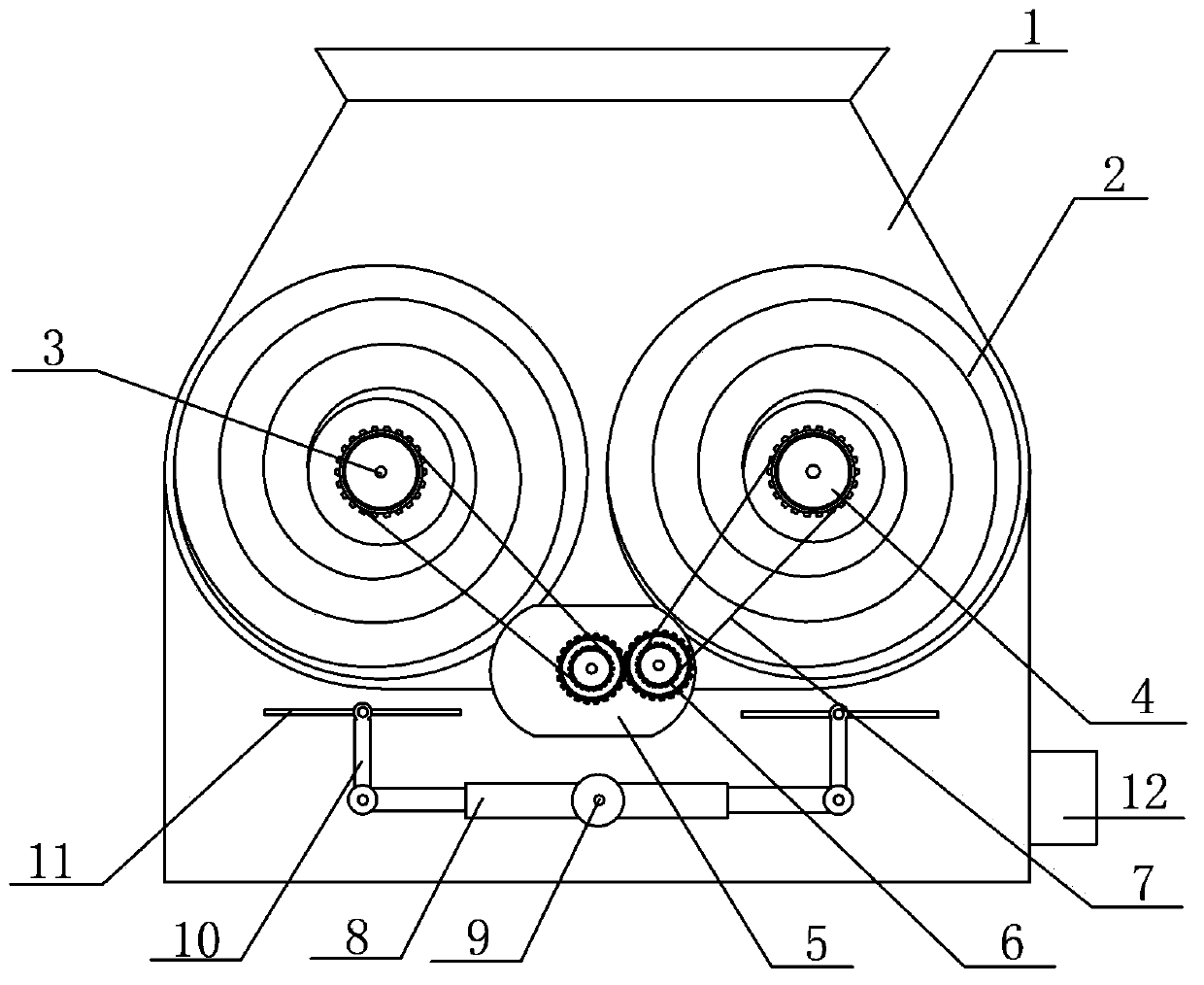

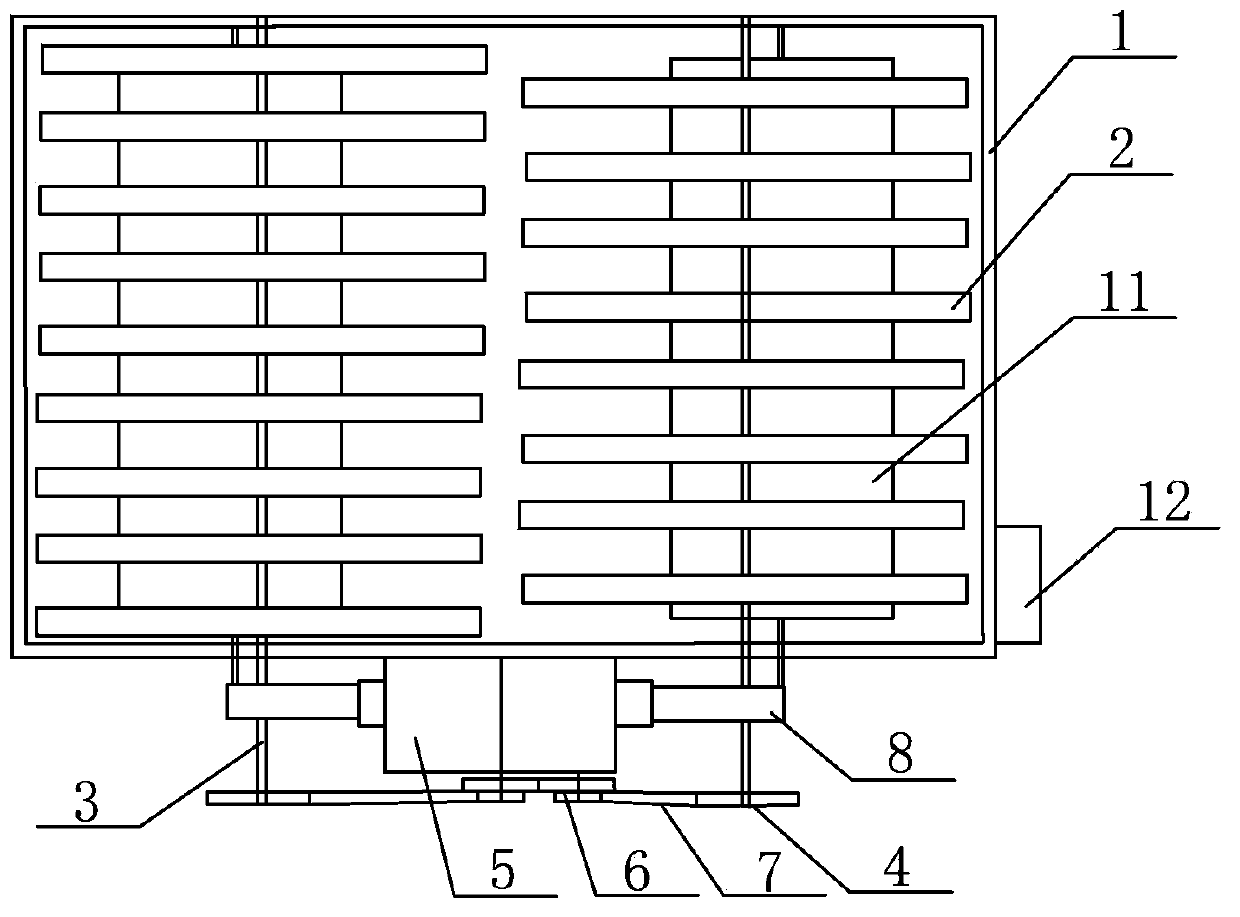

[0011] Such as figure 1 , 2 As shown, the present invention installs bearings 3 with helical pieces 2 on the left and right parts of the inside of the casing 1, and installs a single-layer gear 4 on the outer ends of the two bearings 3, and the motor 5 is installed on the outside of the casing 1 and It is located in the lower part of the middle of the casing 1; double-layer gears 6 are respectively installed on the right side of the rotating shaft of the motor 5 and the above-mentioned rotating shaft. The left and right two single-layer gears 4 are connected, and the two hydraulic rods 8 are jointly fixed on the rotating shaft seat 9 of the casing 1 below the motor 5. The other end of the hydraulic rod 8 is connected to the discharge plate 11 through the transmission rod 10, and the distribution box 12 Installed on the right side of the casing 1 and connected with the motor 5 and the hydraulic rod 8 through wires.

[0012] Through the above settings, the power supply of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com