Method for preparing material liquid capable of improving sensory quality of rolled sheet shreds

A technology of sensory quality and flake silk, which is applied in the preparation of tobacco, application, tobacco, etc., can solve the problems of obvious woody gas and poor aroma of thin silk by rolling method, and achieve the effect of reliable method, reducing waste and saving raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

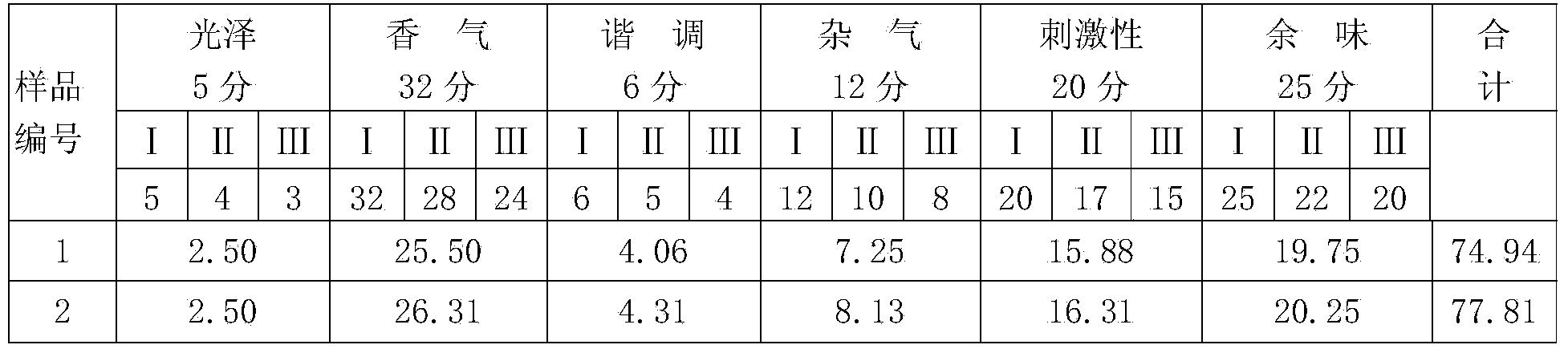

Examples

Embodiment 1

[0023] (1) Tobacco leaf fragments less than 3mm and 15% alcohol aqueous solution are added to the stainless steel extraction tank at a weight ratio of 1:7.

[0024] (2) Heat the mixture in the extraction tank to 55°C and keep stirring for 1.5h.

[0025] (3) After the leaching is completed, put the liquid in the leaching tank on the vibrating sieve for the first solid-liquid separation; after the first solid-liquid separation is completed, the solid material on the vibrating sieve is transported to the centrifuge, The second solid-liquid separation is carried out, and the liquid obtained by the two solid-liquid separations is collected in the liquid storage tank.

[0026] (4) Take the extract and put it into the preparation tank, then add licorice powder with 0.25% by weight of the extract, menthol with 0.03% by weight of the extract, fenugreek tincture with 0.05% by weight of the extract, and the extract 6% glycerol by weight.

[0027] (5) After stirring the various ingredie...

Embodiment 2

[0029] (1) Tobacco leaf fines less than 3mm and 20% alcohol aqueous solution are added to the stainless steel extraction tank at a weight ratio of 1:8.

[0030] (2) Heat the mixture in the extraction tank to 65°C and keep stirring for 2 hours.

[0031] (3) After the leaching is completed, put the liquid in the leaching tank on the vibrating sieve for the first solid-liquid separation; after the first solid-liquid separation is completed, the solid material on the vibrating sieve is transported to the centrifuge, The second solid-liquid separation is carried out, and the liquid obtained by the two solid-liquid separations is collected in the liquid storage tank.

[0032] (4) Take the extract and put it into the preparation tank, then add licorice powder with 0.3% weight of the extract, menthol with 0.04% of the weight of the extract, fenugreek tincture with 0.06% of the weight of the extract, and the extract 7% propylene glycol by weight.

[0033] (5) After stirring various i...

Embodiment 3

[0035] (1) Tobacco leaf fines less than 3mm and 20% alcohol aqueous solution are added to the stainless steel extraction tank at a weight ratio of 1:8.

[0036] (2) Heat the mixture in the extraction tank to 65°C and keep stirring for 2 hours.

[0037] (3) After the leaching is completed, put the liquid in the leaching tank on the vibrating sieve for the first solid-liquid separation; after the first solid-liquid separation is completed, the solid material on the vibrating sieve is transported to the centrifuge, The second solid-liquid separation is carried out, and the liquid obtained by the two solid-liquid separations is collected in the liquid storage tank.

[0038] (4) Take the extract and put it into the preparation tank, then add licorice powder with 0.4% weight of the extract, menthol with 0.02% of the weight of the extract, fenugreek tincture with 0.04% of the weight of the extract, and the extract 8% propylene glycol by weight.

[0039] (5) After stirring various i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com