Ultrasonic flow rate measurement device

A flow measurement and ultrasonic technology, which is applied in the field of ultrasonic flow measurement devices, can solve the problems of increased man-hours, difficulty in reducing power consumption, and material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

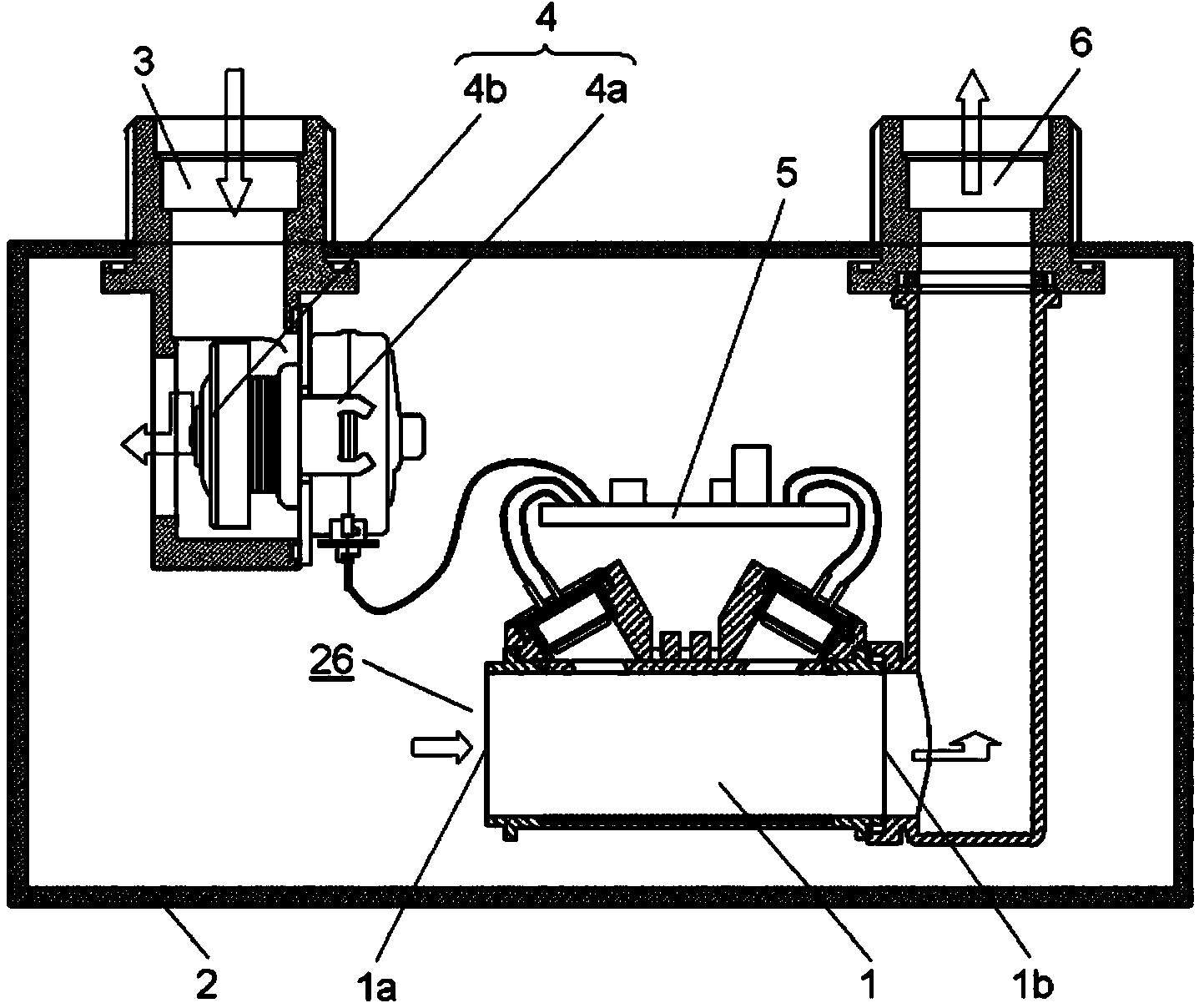

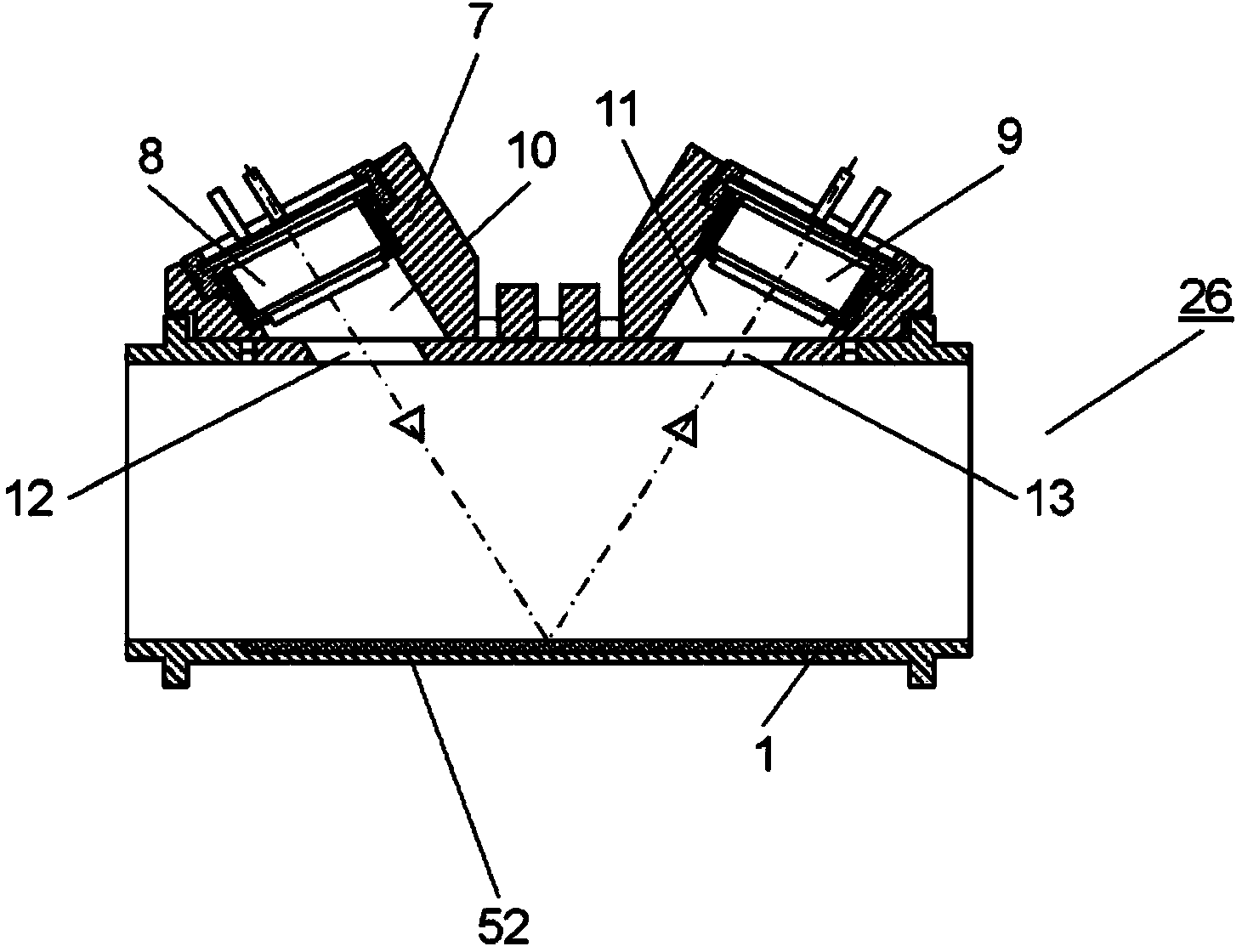

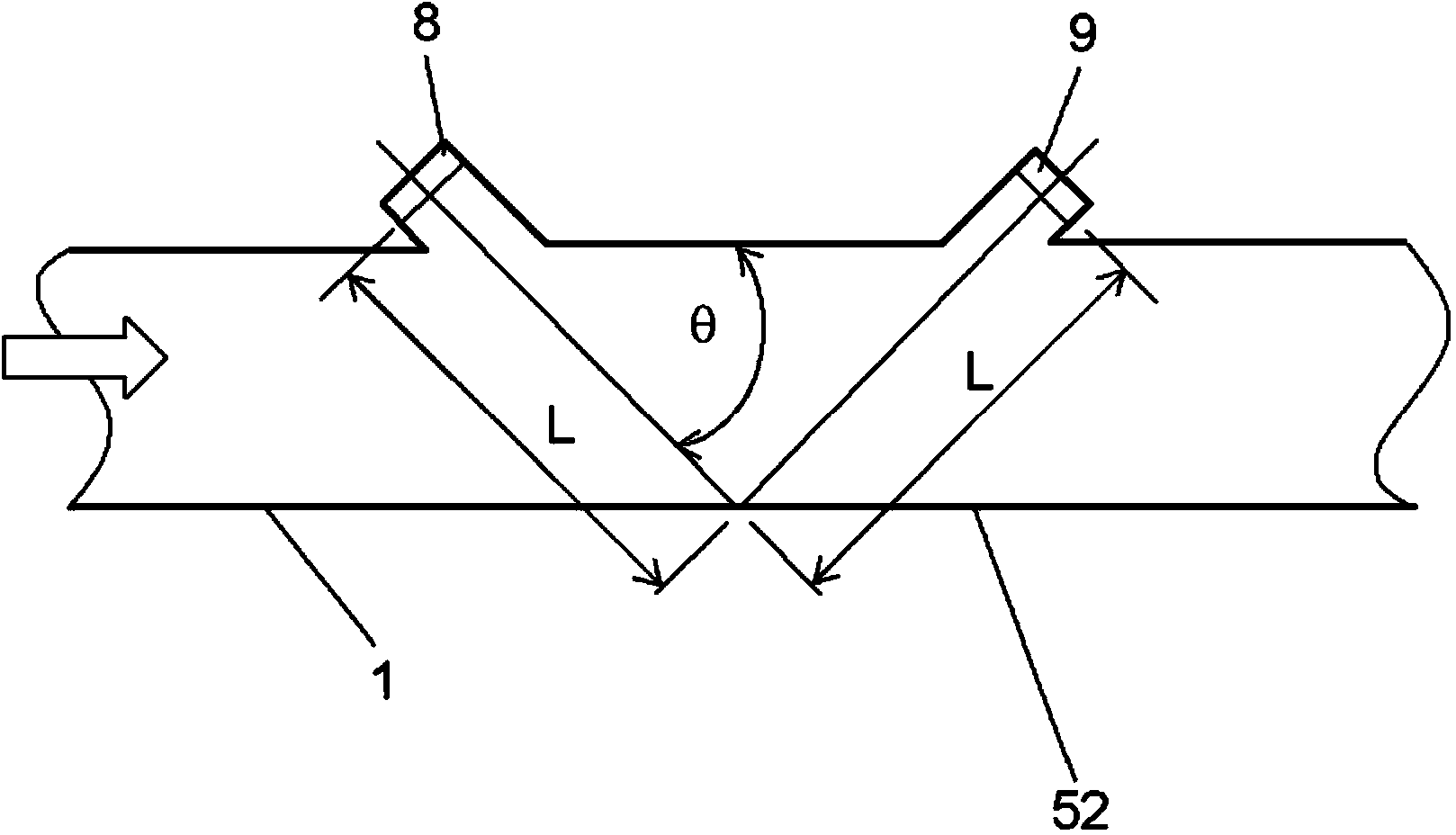

[0031] figure 1 It is a cross-sectional view showing the structure of the ultrasonic flow rate measuring device 50 in the embodiment of the present invention. figure 1 The hollow arrow indicates the flow of fluid (fluid to be measured).

[0032] Such as figure 1 As shown, the ultrasonic flow rate measuring device 50 includes a fluid supply path 3. The fluid supply path 3 has a shut-off valve 4 in the middle of the flow path. The shut-off valve 4 includes a drive portion 4a and a valve body 4b that cooperates with the drive portion 4a, and is opened and closed by the valve body 4b, wherein the drive portion 4a includes a step Into electromagnetic devices such as motors. In a state where the shutoff valve 4 is open, the fluid to be measured flows out of the fluid supply path 3 into the inside of the measuring instrument housing 2. The ultrasonic flow rate measurement device 50 includes a measurement flow path 1 through which a fluid to be measured flows. The measurement flow p...

no. 2 approach

[0069] Picture 11 It is a perspective view showing the structure of the slide mold 32 in the second embodiment of the present invention. Picture 12 It is a perspective view showing the structure of the sensor mounting housing 7 in the second embodiment of the present invention.

[0070] The structures of the ultrasonic flow rate measuring device 50 and the mold in this embodiment are the same as those of the first embodiment except for the structure of the slide mold 32, so the description thereof is omitted.

[0071] In this embodiment, as Picture 11 As shown, a grid-shaped groove 33 is formed at the front end of the sliding mold 32. The groove 33 is formed in a direction perpendicular to the flow in the measurement flow path 1, and the depth direction of the groove 33 is configured to be perpendicular to the ultrasonic radiation surface of the pair of ultrasonic sensors 8 and 9. The opening direction of the molded lattice-shaped suppressor 34 is perpendicular to the transmitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com