Sewing machine

A sewing machine and motor technology, which is applied to sewing machine components, sewing equipment, sewing machine control devices, etc., can solve the problems of not being able to fully realize the burden of workers, reduce the burden, and reduce the confusion of stitch formation, and suppress the confusion and burden. lightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] [Structure of Sewing Machine]

[0050] Next, a sewing machine 10 as an embodiment of the present invention will be described with reference to the drawings.

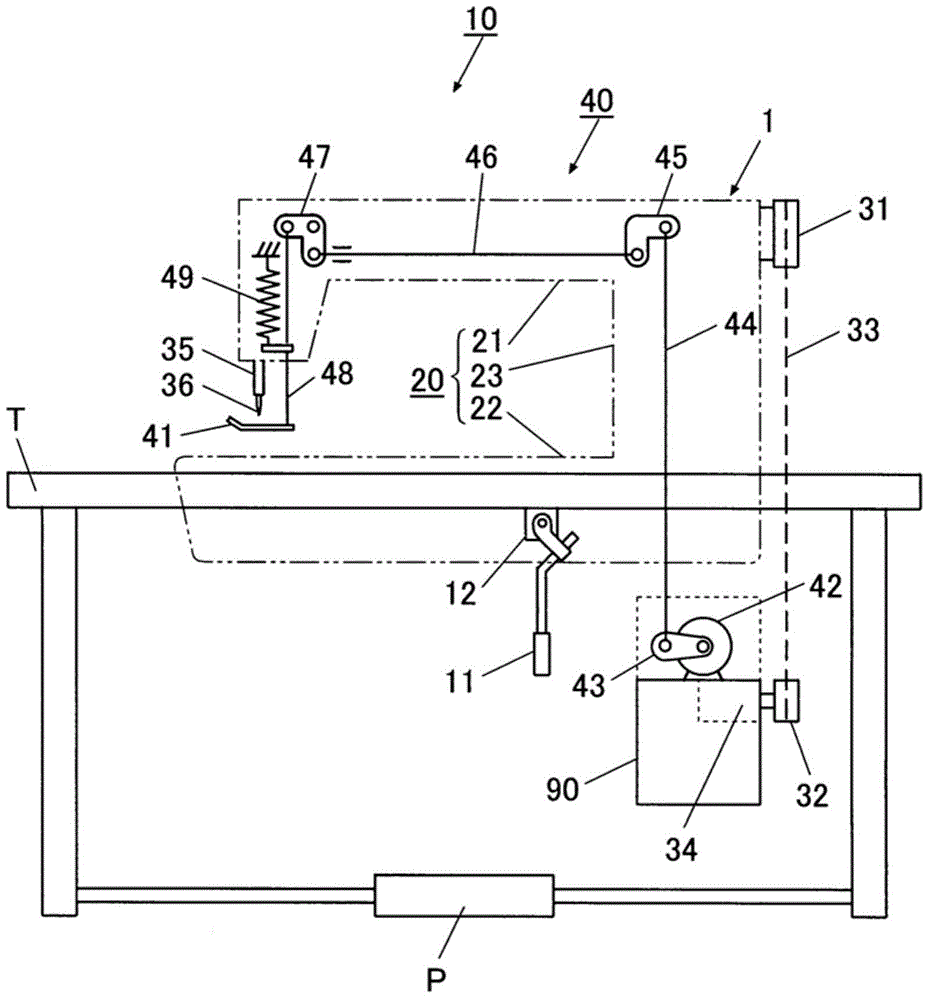

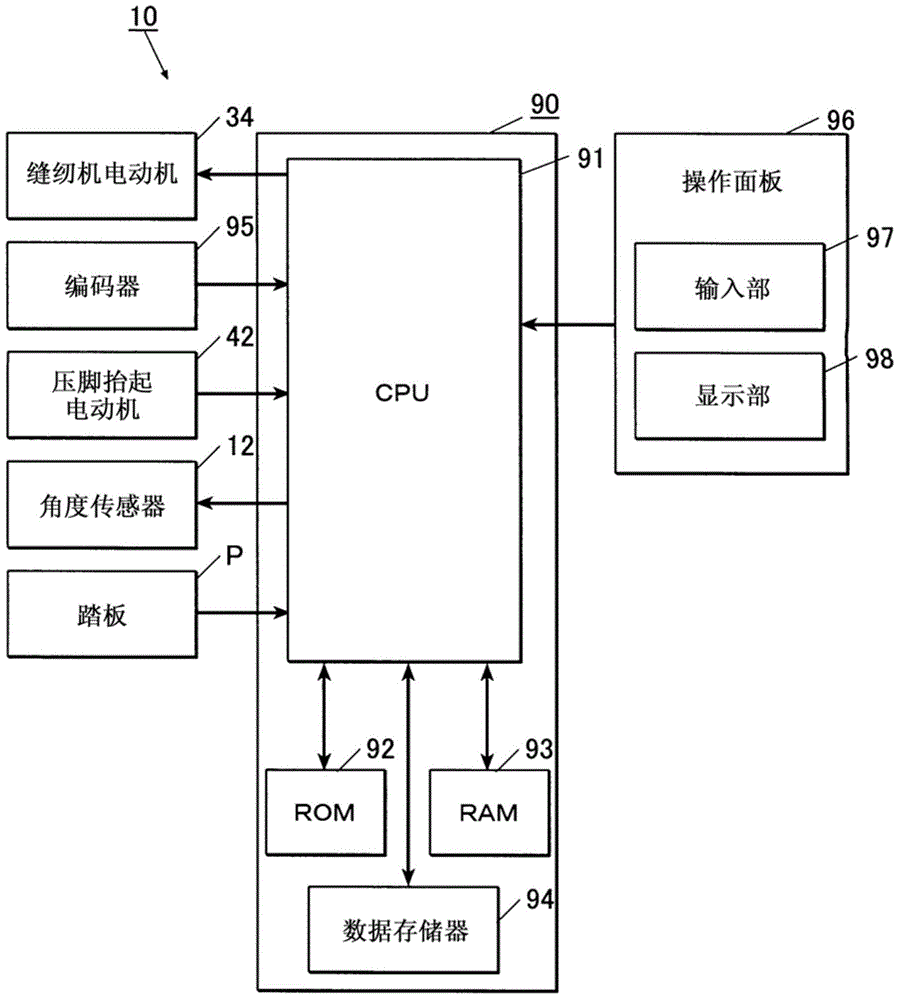

[0051] sewing machine 10 as figure 1 As shown, there are: a sewing machine main body 1, which is arranged on the sewing machine table T; a pedal P as a starting unit, which is arranged at the lower part of the sewing machine table T, and is used for starting the sewing machine motor described later and operating the rotation speed ; and the control unit 90, which centrally controls the various parts of the sewing machine.

[0052] Sewing machine body 1 such as figure 1 Shown is a sewing machine frame 20 having a substantially U-shaped outer shape when viewed from the side. This sewing machine frame 20 has: a sewing machine arm portion 21, which forms an upper portion of the sewing machine main body 1, extending in the left-right direction; a sewing machine base portion 22, which forms a lower portion of the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com