Stopping machine special for low-temperature tanker loading and unloading arm

A technology of loading and unloading arms and cryogenic tanks, which is applied in the direction of tank trucks, hoses, pipes, etc., to achieve the effect of easy pushing or insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

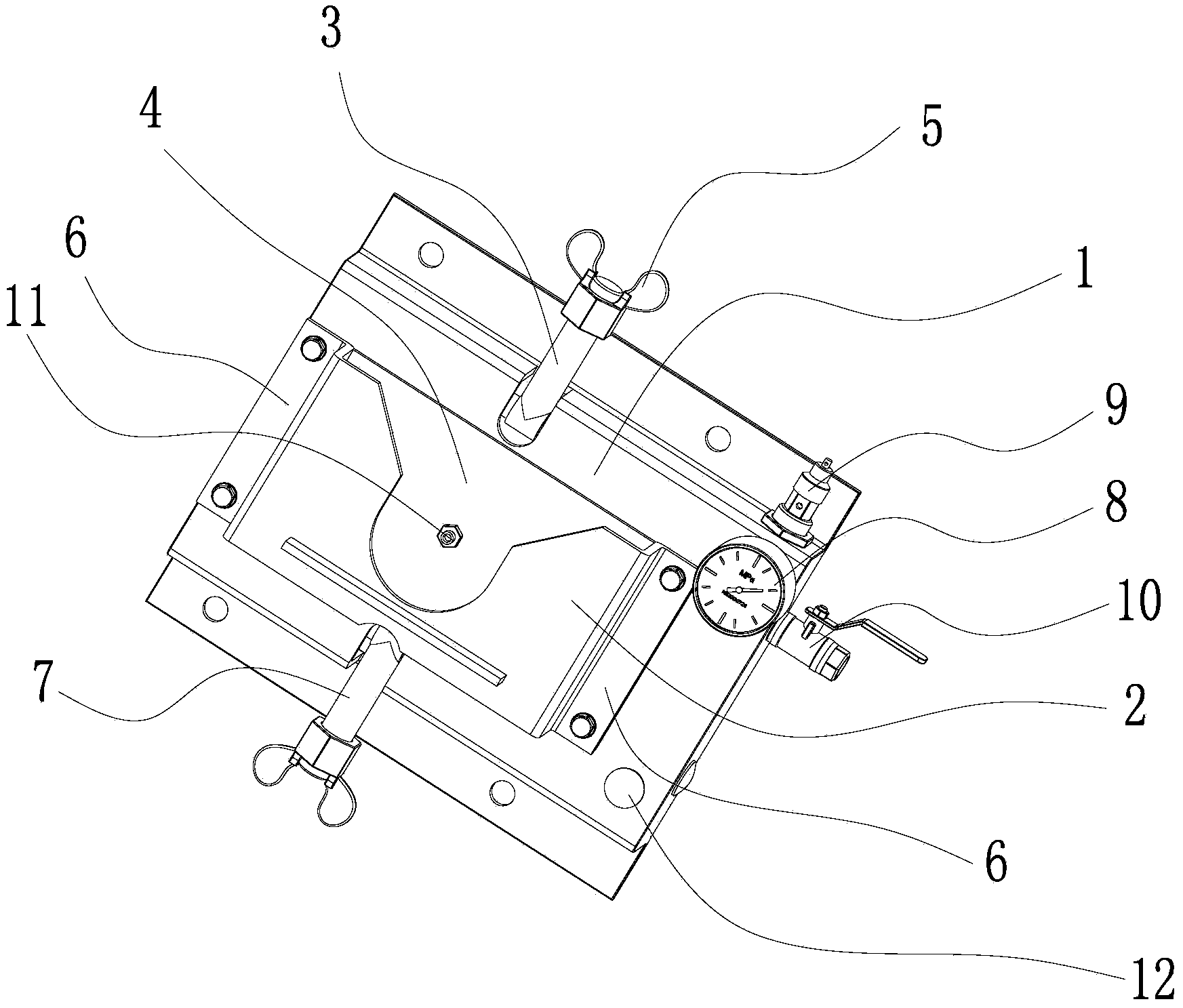

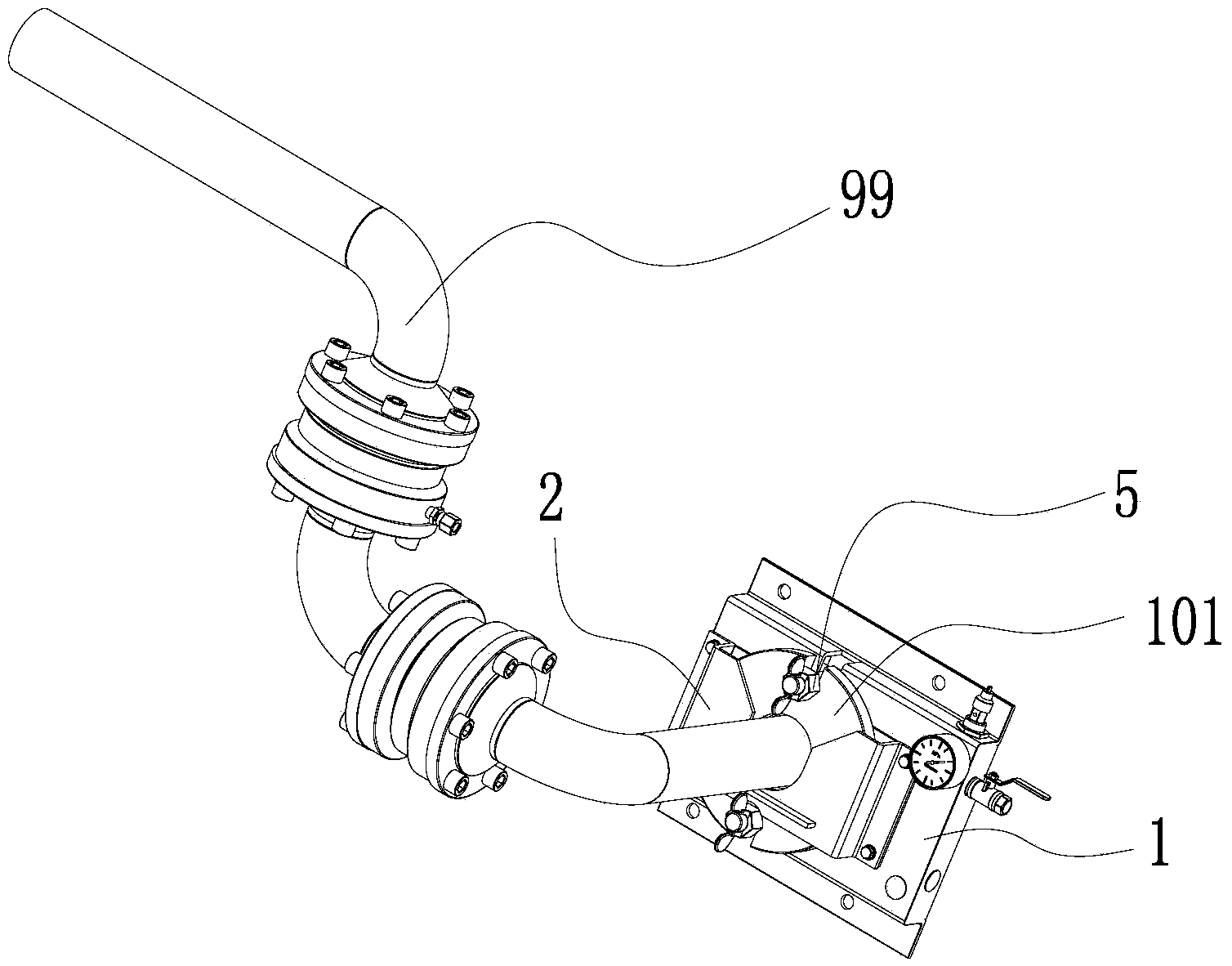

[0026] The stopper in the present invention is used to dock the low-temperature tanker arm 99 on the low-temperature liquid tanker. The outlet of the low-temperature tanker arm 99 is provided with a flange 101, and the flange 101 is provided with a first opening bolt groove. according to figure 1 As shown, it includes a main board 1 and a sub-board 2 that are stacked and connected to each other in a plane; and a first flange limit bolt 3 is also included.

[0027] Wherein, a cavity capable of accommodating the flange 101 is formed between the middle protrusion of the sub-board 2 and the main board 1, and a U-shaped notch is formed on the sub-board 2 to accommodate the entry and placement of the loading and unloading arm 99 of the low-temperature tanker.

[0028] The first flange limit bolt 3 includes bolt cylinders and pin shafts that are vertically intersected and connected. The main board 1 is provided with a second open bolt groove that can accommodate the bolt cylinders to...

Embodiment 2

[0035] In order to perform air tightness detection after the low-temperature tanker loading and unloading arm 99 is connected, this embodiment is an improvement on the basis of Embodiment 1, and also includes a valve group connector (not shown in the figure), the valve group connector has The first outlet, the second outlet and the third outlet, the first, second and third outlets are sequentially connected with a pressure gauge 8, a safety valve 9 and an exhaust valve 10, an air source hole 11 is opened on the main board 1, and the air source The hole 11 corresponds to the center of the flange 101, and the air source hole 11 connector is installed on the air source hole 11, and the air source hole 11 connector is connected to the valve group connector through a gas pipe.

[0036]When carrying out seal detection, open the nitrogen inlet valve on the low-temperature tanker loading arm 99, fill nitrogen into the low-temperature tanker loading arm 99, the pressure gauge 8 shows th...

Embodiment 3

[0039] In order that the docking device in the present invention can be compatible with left-handed and right-handed low-temperature tanker loading and unloading arms 99, further, the main board 1 is provided with an installation reserved hole 12 for installing the valve group connector, and the installation reserved hole 12 With sealing cap. The middle part of the main board 1 is a step-shaped protrusion, and the two sides of the main board 1 are respectively provided with bolt installation holes. The first opening bolt groove is arranged at the edge of the stepped protrusion. Install the reserved hole 12, the installed reserved hole 12 is provided with a sealing cap, the valve group connector can be connected to the installation reserved hole after the sealing cap is removed, the sub-board 2 and the main board 1 are connected by bolts, The sub-board 2 can be connected to the main board 1 again after being turned 180 degrees.

[0040] figure 1 The stopper shown is suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com