A fan for three-phase asynchronous motor

A three-phase asynchronous, electric motor technology, applied in the field of electric motors, to achieve the effect of improving efficiency, small size, and reducing wind resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

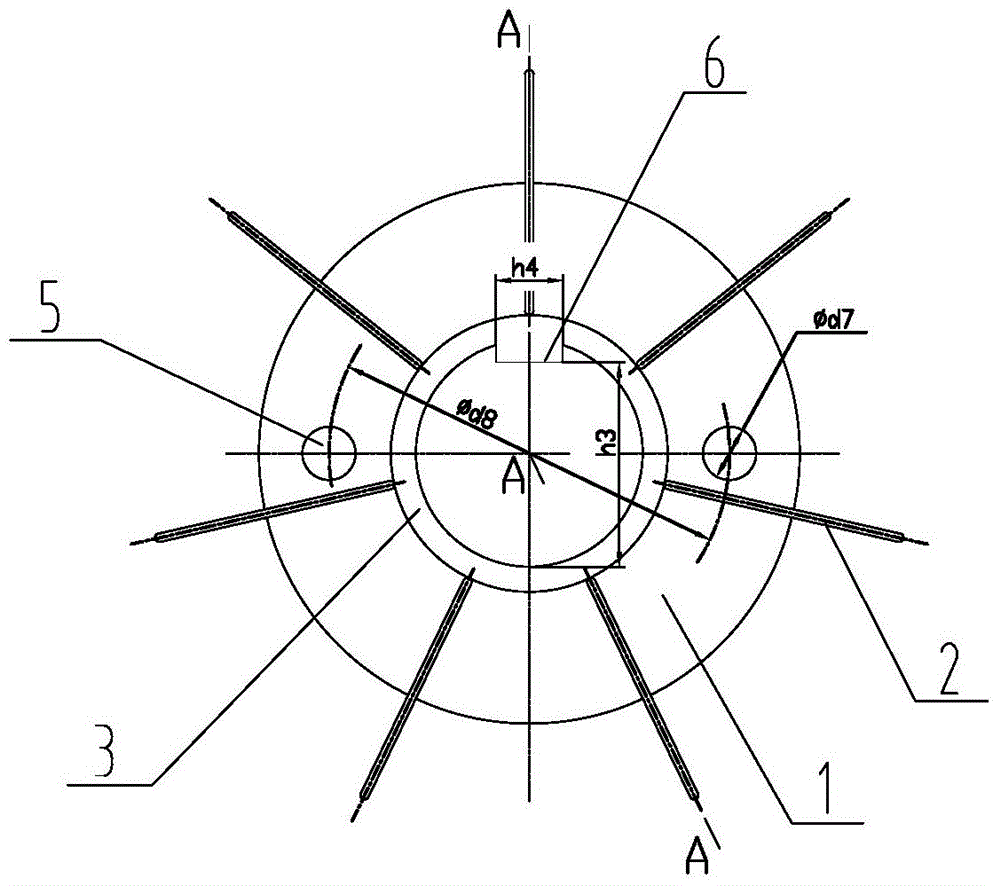

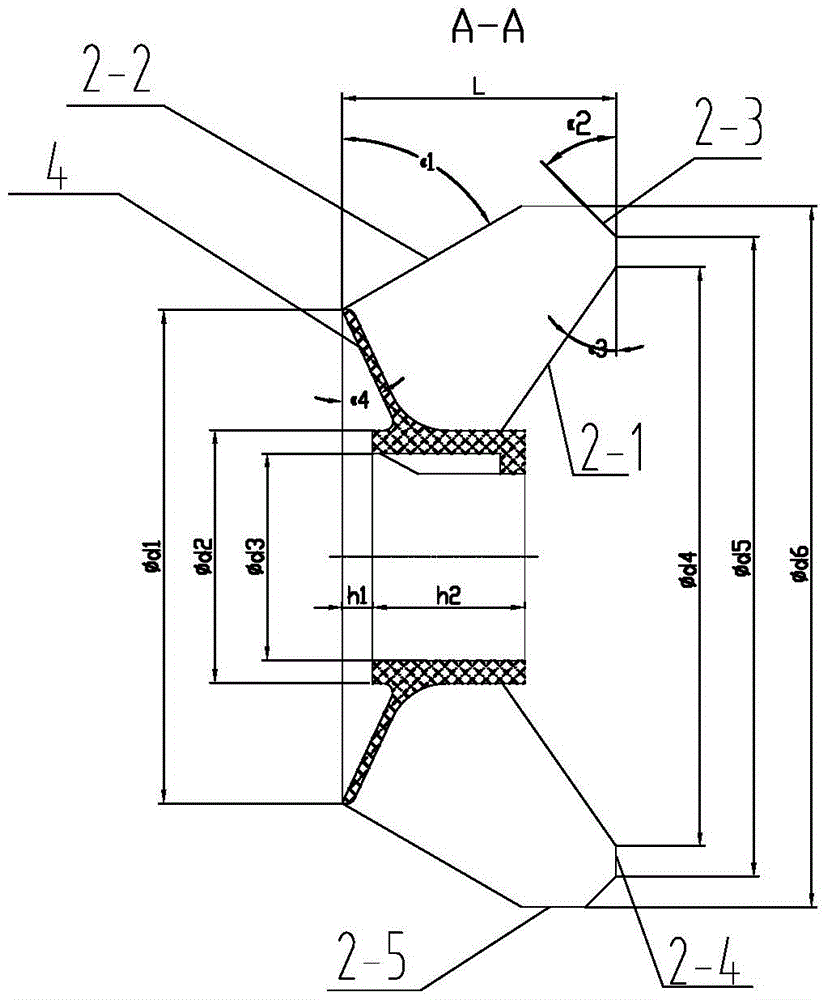

[0018] Such as figure 1 , figure 2 As shown, it includes fan body 1, fan blade 2, bottom edge 2-1, upper edge 2-2, top edge 2-3, first chamfer 2-4, second chamfer 2-5, bushing 3, cone Shaped barrel 4, ventilation hole 5, connecting groove 6 etc.

[0019] Such as figure 1 , figure 2 As shown, the present invention is a fan for a three-phase asynchronous motor, including a fan body 1, the thickness L of the fan body 1 is 90mm, and a shaft sleeve 3 is fixed at the center of the fan body 1, and the outer diameter of the shaft sleeve 3 is φd2 is 83mm, the inner diameter φd3 of the shaft sleeve 3 is 68mm, and the peripheral surface of the shaft sleeve 3 is provided with a tapered barrel 3-1, the inner diameter φd1 of the tapered barrel 3-1 is 162mm, and several Fan blades 2, both ends of the root of each fan blade 2 are fixedly arranged on the outer end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com