Novel oil-well pump

An oil pump, a new type of technology, applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems of stuck pump, increase of plunger descending resistance, increase of leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

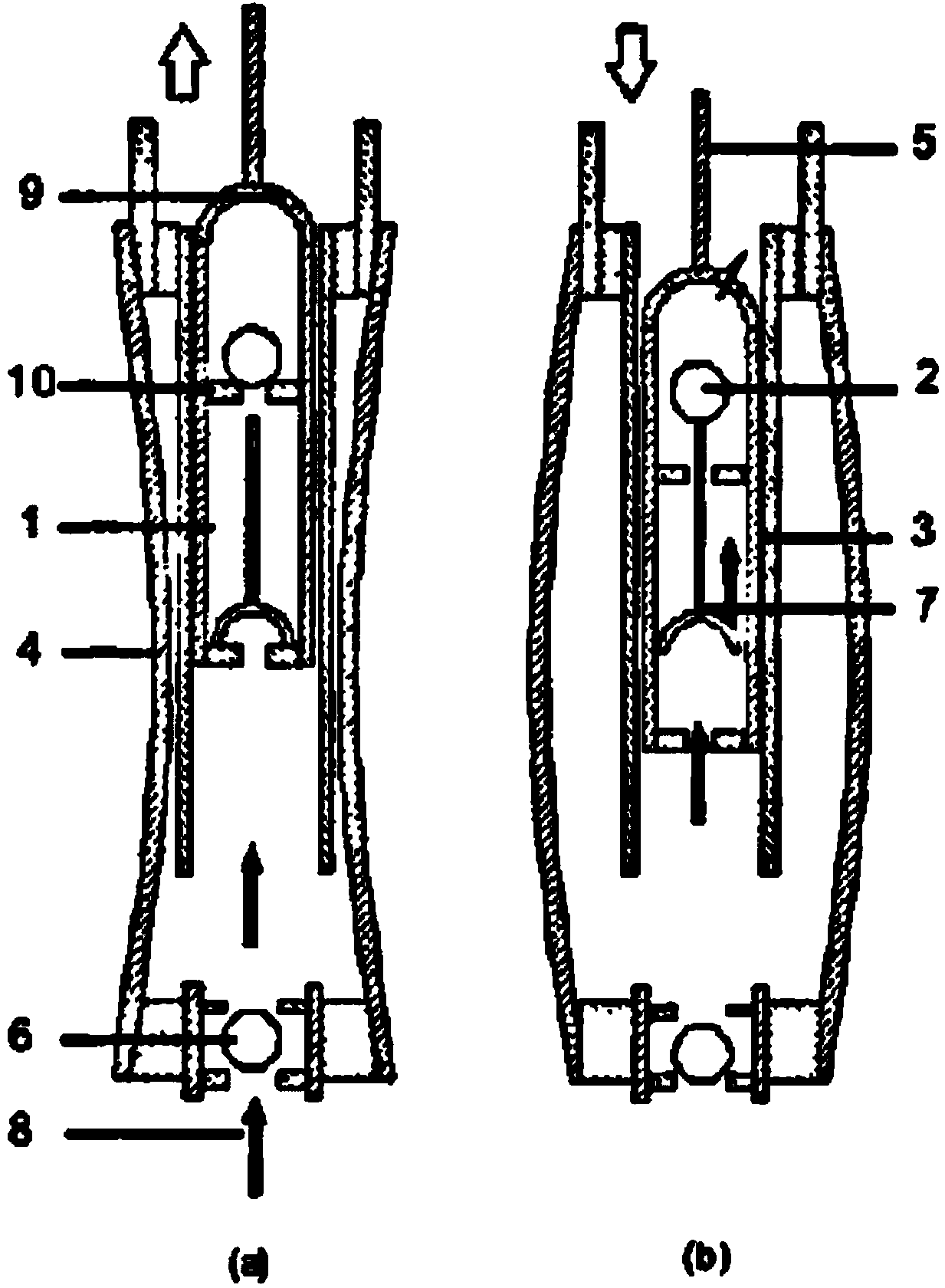

[0007] The upstroke sucker rod 5 drives the plunger 1 to move upward, as shown in Figure l(a). The volume of the pump chamber increases and the pressure decreases, the floating valve closes, the fixed valve opens, and the formation produced fluid enters the pump chamber. At this time, the outer pump barrel 4 shrinks under the action of the pressure difference inside and outside the pump chamber, while the pressure on the inner and outer walls of the inner pump barrel 3 is equal and does not deform.

[0008] Downstroke plunger 1 moves downward, as shown in Figure l(b). The volume of the pump chamber becomes smaller and the pressure rises, the fixed valve closes, and the plunger 7 of the floating valve opens under the action of high pressure at its lower end, and pushes the ball 10 of the floating valve, and the gas-liquid mixture in the pump chamber enters through the outlet smoothly. Oil pipe, there will be no lag in the opening of the floating valve or even the problem of "a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com