Automatic wall surface milling machine

The utility model relates to a wall milling machine and automatic technology, which is applied in the directions of building maintenance, construction and building structure, etc. It can solve the problems of detrimental to the physical and mental health of construction workers, difficulty in eradication, and high labor intensity, so as to improve construction quality and work. Efficiency, beneficial to health and environmental protection, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

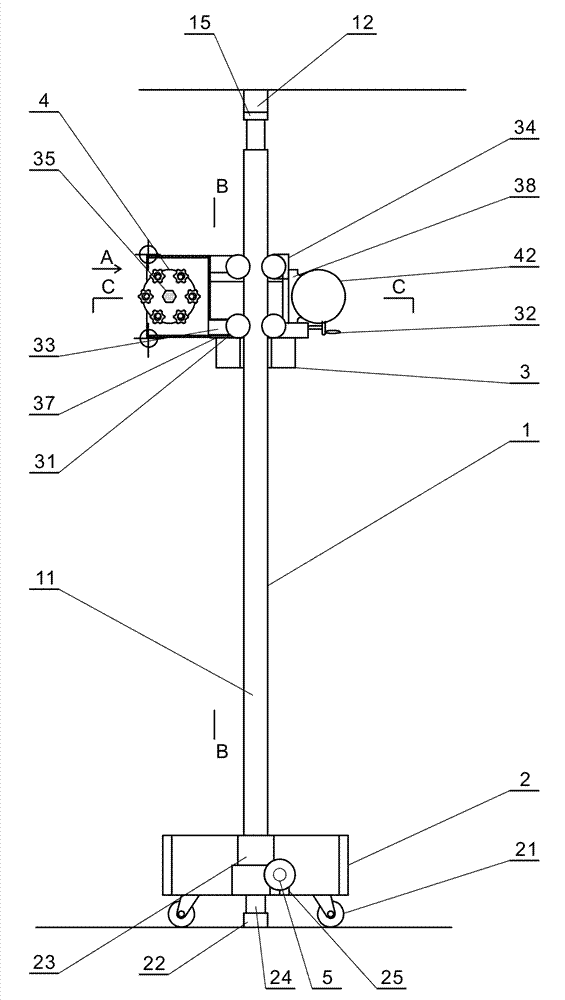

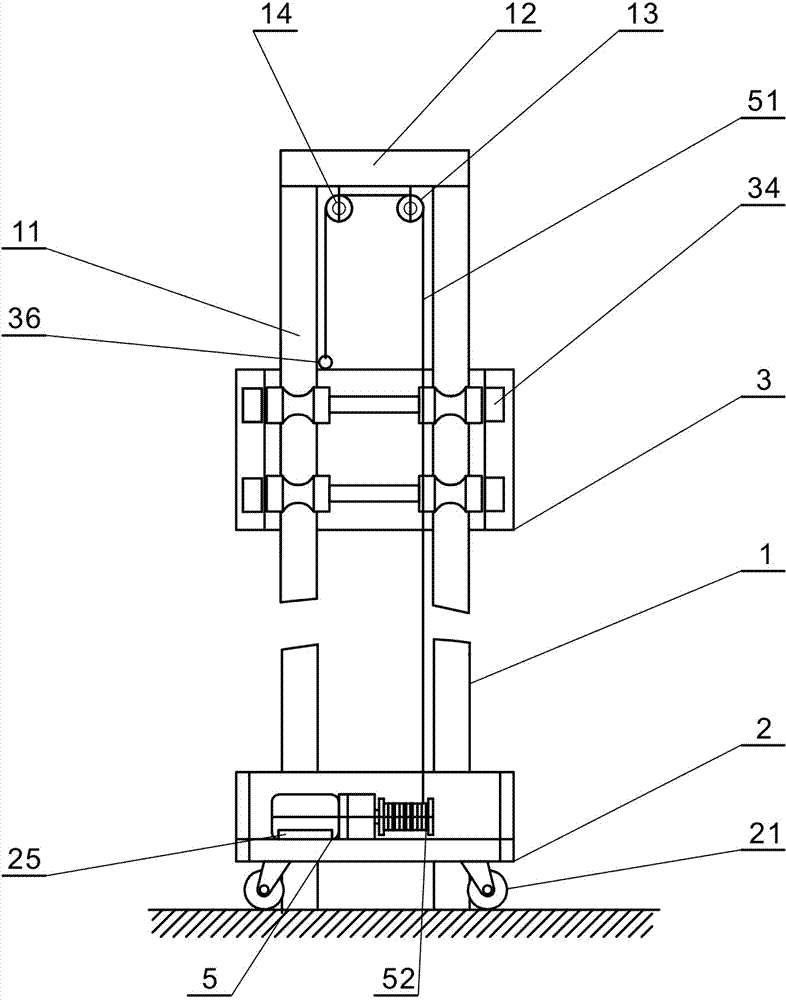

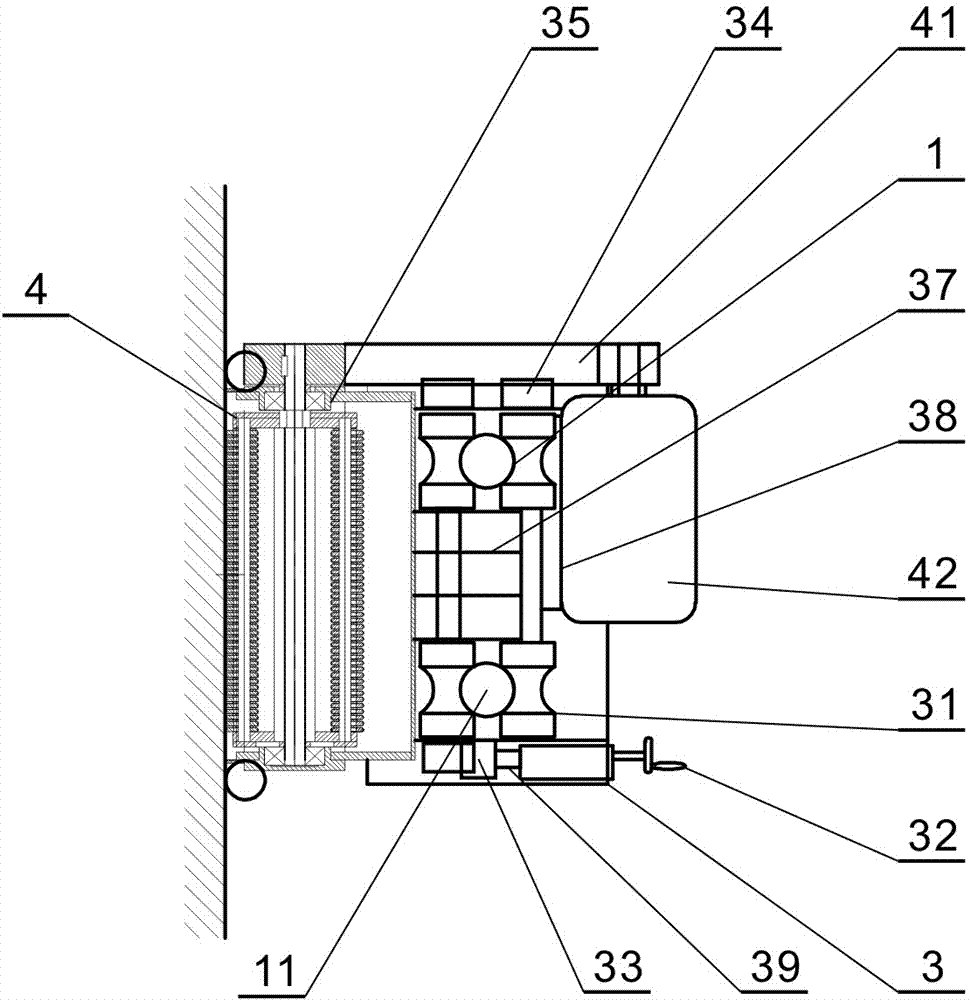

[0014] see figure 1 , figure 2 , image 3 , Figure 4 , The present invention includes a frame 1, a base 2, a pallet box 3, a milling head 4 and a lift 5. The frame 1 consists of a telescopic column 11, a beam 12 and a pulley block 13. The telescopic column 11 is provided with a telescopic column in the axial direction. The screw, the cross beam 12 is provided with a pulley shaft seat 14 and a telescopic screw seat 15, two telescopic columns 11 are arranged in parallel, the beam 12 is arranged between the two top ends of the telescopic column 11, and the telescopic screw seat 15 and the telescopic column 11 are telescopic The screw is hinged, the pulley group 13 is hinged on the pulley shaft seat 14 of the beam 12, the base 2 includes a movable caster 21 and a locking mechanism 22, and the base 2 is plate-shaped with a column seat 23 and a winch seat 25 on the top, and a lock on the bottom surface. The locking mechanism seat 24, the movable casters 21 are arranged on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com