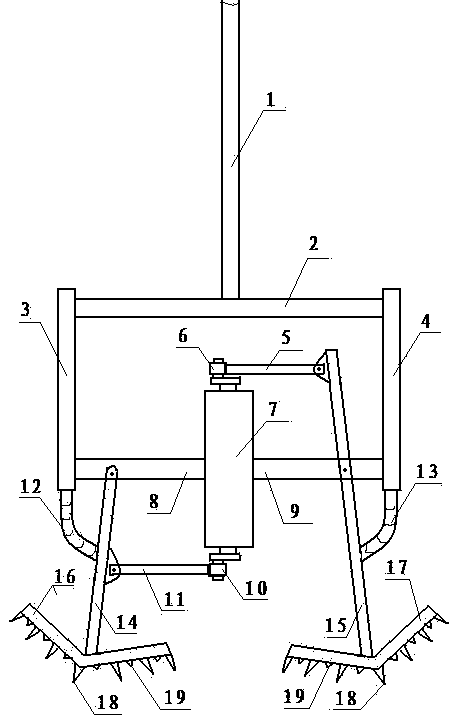

Double-shaft-end electric trencher

A technology of electric motors and trenchers, which is applied to earth movers/shovels, construction, etc., can solve the problems of slow trenching speed, high cost, and complex structure, and achieve high trenching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment connects the lower end of long steel pipe 1 and is connected in the middle of horizontal pipe 2, and the left and right sides of horizontal pipe are respectively connected with the upper end of left standpipe 3 and right standpipe 4, and the lower end of left standpipe The left steel wire elbow 12 is connected, the left steel wire elbow lower end is connected with the left inclined pipe 14, the right vertical pipe lower end is connected with the right steel wire elbow 13, and the right steel wire elbow lower end is connected with the right inclined pipe 15; Double shaft end motor 7, the left end of the double shaft end motor is fixed on the left support beam 8, the right end is fixed on the right support beam 9, the upper end of the double shaft end motor is fixed with an upper eccentric shaft 6, and the upper eccentric shaft is hinged through the upper connecting rod 5 Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com