High-speed magnetic suspension type driving Jacquard knitting needle circular weft knitting machine

A magnetic levitation and knitting needle technology, which is applied to circular weft knitting, knitting, weft knitting and other directions with separate action needles, can solve problems such as restricting the performance of knitting jacquard circular weft knitting machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

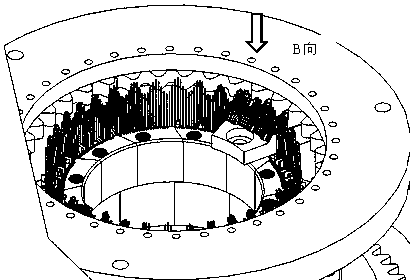

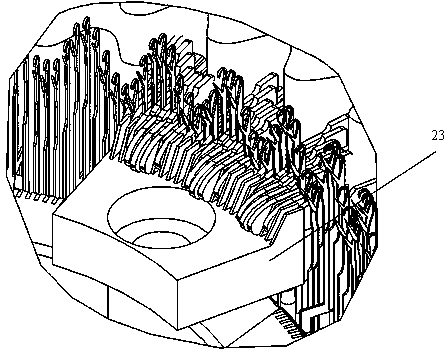

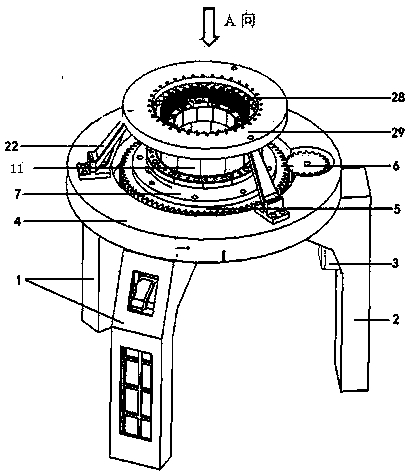

[0022] attached Figure 1-4 Marking description in: small machine foot 1, large machine foot 2, servo motor 3, large table top 4, large gear 5, small gear 6, syringe base 7, syringe base fixing hole 8, wire hole 9, syringe parts Positioning hole 10, needle cylinder device 11, needle cylinder part 11.1, needle cylinder part fixing hole 12, needle cylinder part disassembly line 13, needle cylinder part fixing screw 14, needle cylinder part positioning pin 15, knitting needle hole 16, inner ring Knitting needle holes 17, middle loop knitting needle holes 18, outer loop knitting needle holes 19, magnetic levitation drive knitting needles 20, sinker ring fixing screw holes 21, standoffs 22, sinker ring 23, sinker ring installation holes 24 , Needle groove 25, sinker groove 26, sinker 27, sinker triangle 28, sinker triangle ring 29.

[0023] see figure 1 Schematic diagram of the structure of the embodiment of the present invention, the frame part includes a small machine foot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com