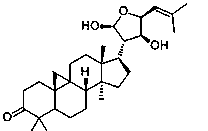

Preparation method of sliver-white aglaione A

A technology for silver white milanone and silver white milanone A is applied in the field of preparation of silver white milanone A, which can solve the problems of complicated operation, low sample yield, small preparation amount, etc., and achieves high product purity and simple process. Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Take silver white Mizilan leaves, dry them, crush them, weigh 10kg, add 8 times the amount of 90% ethanol solution, reflux and extract 3 times, the extract will shrink to no alcohol, add appropriate amount of water to dilute it, add it to D101 macroporous resin for adsorption, first use 7 times Column volume 50% ethanol solution to elute impurities, and then use 6 times column volume 80% ethanol solution to elute active ingredients, eluate to recover solvent and place precipitation, precipitate is filtered out and heated to dissolve with 95% ethanol, add appropriate amount of water to alcohol concentration 50%, add an equal volume of petroleum ether and stir thoroughly, collect the petroleum ether layer and filter with suction, collect the filter cake and dissolve the crystals with 80% ethanol solution for 3 times, dry to obtain 3g silver white mizalanone A, the content is 98.3% by HPLC detection.

Embodiment 2

[0015] Take silvery white Mizilan leaves, dry them, crush them, weigh 10kg, add 10 times the amount of 80% ethanol solution, and reflux for extraction twice. 10 times the column volume of 40% ethanol solution to elute the impurities, and then use 5 times the column volume of 90% ethanol solution to elute the active ingredient. Alcohol concentration 40%, add an equal volume of petroleum ether and stir thoroughly, collect the petroleum ether layer and filter with suction, collect the filter cake and dissolve the crystals with 90% ethanol solution for 3 times, dry to obtain 2.7g silver white mizalenone A, which is detected by HPLC. 97.2%.

Embodiment 3

[0017] Take silvery white Mizilan leaves, dry them, crush them, weigh 10kg, add 10 times the amount of 70% ethanol solution, reflux and extract twice, the extract will shrink to no alcohol, add appropriate amount of water to dilute it, then add it to HZ816 macroporous resin for adsorption, first use 7 times Column volume 60% ethanol solution to elute impurities, and then use 5 times column volume 80% ethanol solution to elute active ingredients, eluate to recover solvent and place precipitation, precipitate is filtered out and heated to dissolve with 90% ethanol, add appropriate amount of water to alcohol concentration 50%, add an equal volume of petroleum ether and stir thoroughly, collect the petroleum ether layer and suction filter, collect the filter cake and dissolve the crystals with 90% ethanol solution for 3 times, dry to obtain 3.5g silver white mizalenone A, the content is 97.8% by HPLC detection .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com