Method and device for winding a fibrous web in a winder

A fiber web, winding machine technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., to achieve the effect of simple feeding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the figures, the same reference numerals designate corresponding parts and combinations of parts.

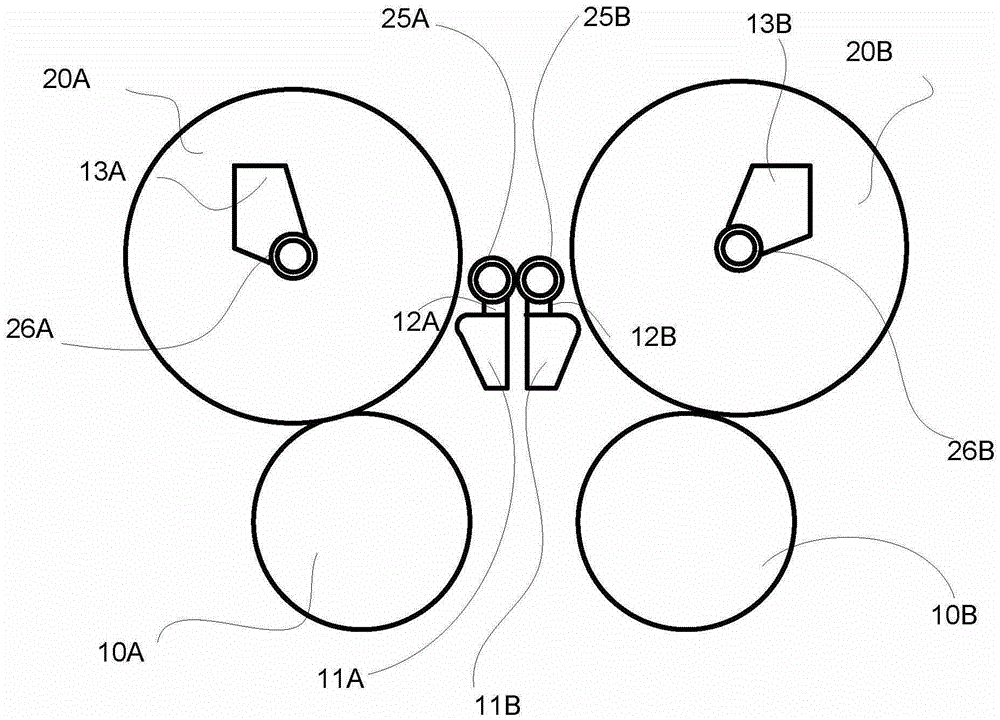

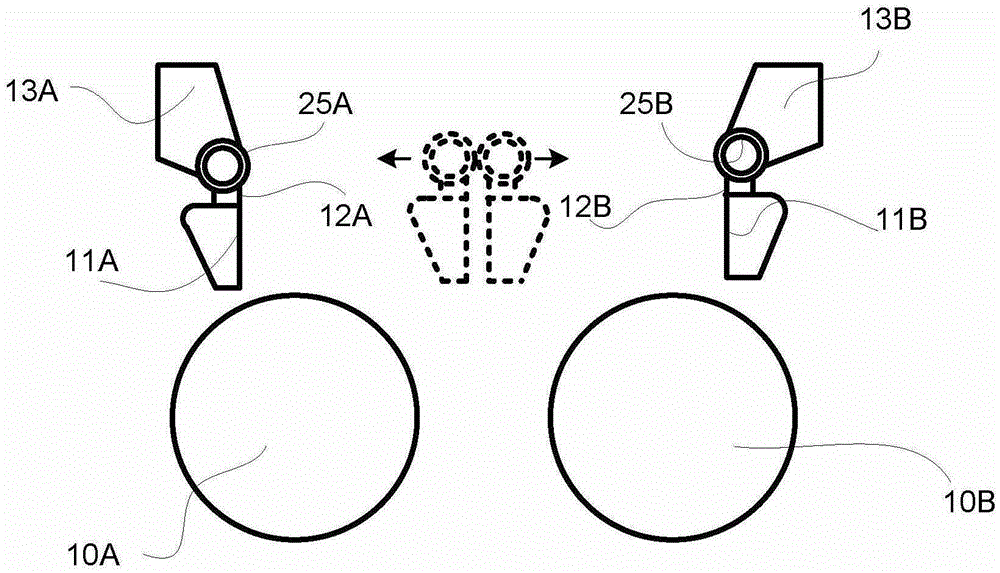

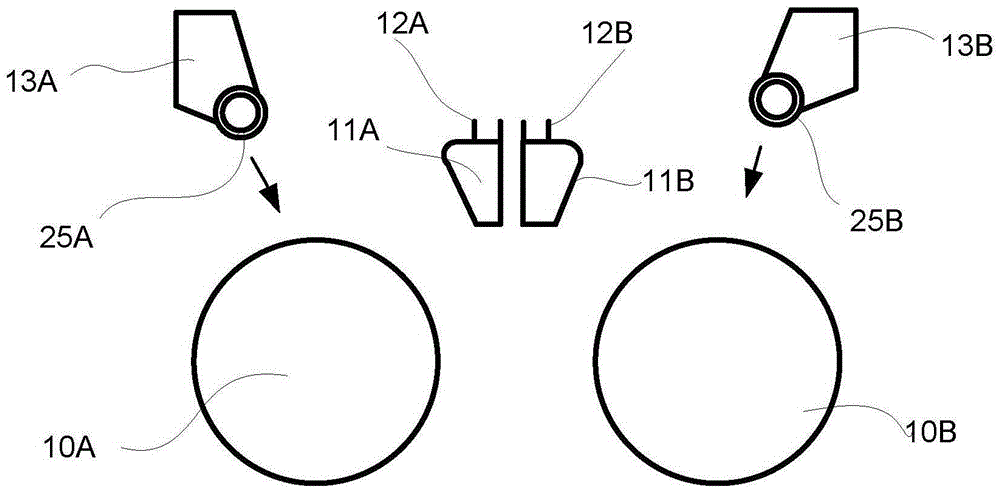

[0029] exist Figure 1 to Figure 3 In the example shown is a winder for winding a partial web comprising two winding rolls 10A, 10B. The partial webs are wound at the winding stations to partial web rolls respectively around cores 26A, 26B via winding nips formed between the partial web rolls 20A, 20B and the winding rolls 10A, 10B. 20A, 20B, these winding stations are arranged successively in the axial direction of the partial web roll 20A, 20B of each winding roll 10A, 10B. The partial web rolls 20A, 20B are supported at the ends of winding cores 26A, 26B by means of winding heads 13A, 13B. The winding machine comprises a core supply system (not shown) and supply beams 11A, 11B; the supply beams 11A, 11B are used to supply new winding cores 25A, 25B into the winding machine, and in the previous set of sections During winding of the web rolls 20A, 20B close to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com