Hollow capsule ring conveying device

A hollow capsule and circular conveying technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of large floor area, high investment cost, and existing defects, so as to reduce investment costs and occupy an area The effect of small area and regular arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

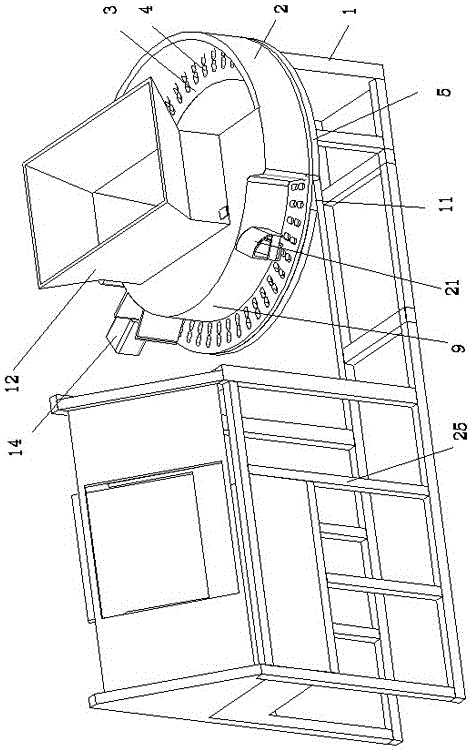

[0032] like figure 1 Shown is a schematic structural view of an embodiment of the hollow capsule annular delivery device of the present invention. The annular conveying device for hollow capsules in this embodiment includes a frame 1, on which a feeding device and a material distributing device are arranged.

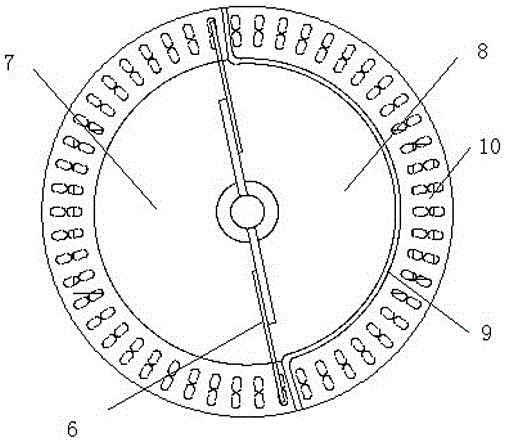

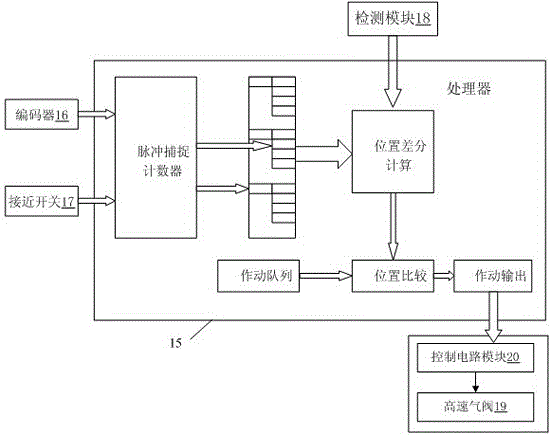

[0033] The distributing device includes a storage compartment 2 arranged below the feeding device, a feeding turntable 3 at the bottom of the storage compartment 2, a capsule tray 5 for supporting the feeding turntable, and a driving mechanism for driving the rotation of the feeding turntable 3. The feeding turntable 3 There is a hole 4 for storing the empty capsules for at least one week, and the storage compartment 2 is provided with a cleaning mechanism for cleaning the empty capsules that are not in the hole 4 or swee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com