Forging machine air cushion structure

A technology for forging presses and air cushions, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc. Convenience, overcoming easily damaged air cushion, good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

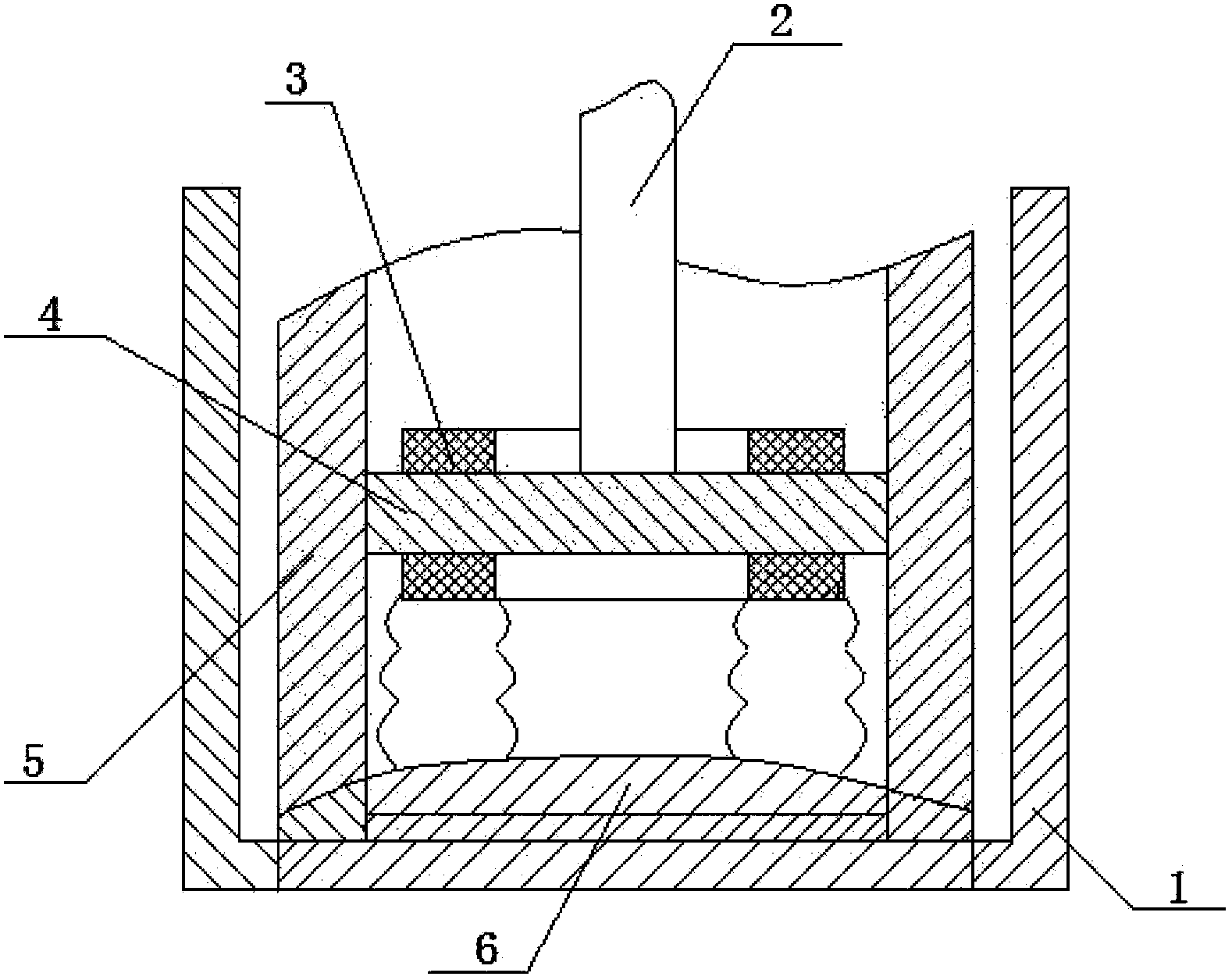

[0009] The air cushion structure has a structure (1), and a silica gel filling pad (6) is placed at the bottom of the structure (1); a piston rod (2) is installed at the middle end of the structure (1), and the piston rod (2) and The piston (4) is connected with each other, the piston (4) is installed in the cylinder (5), and can move up and down in the cylinder (5), the silicone buffer pad (3) is installed on the piston (4) and fixed on it by its own bolts Above the up and down position of the piston (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com