Split type fermentation cabinet

A fermentation cabinet and split-type technology, applied in the field of split-type fermentation cabinets, can solve the problems that the fermentation cabinet occupies space, cannot be disassembled at will, and is inconvenient to transport the fermentation cabinet, and achieves low implementation cost, simple, reasonable and compact structure, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

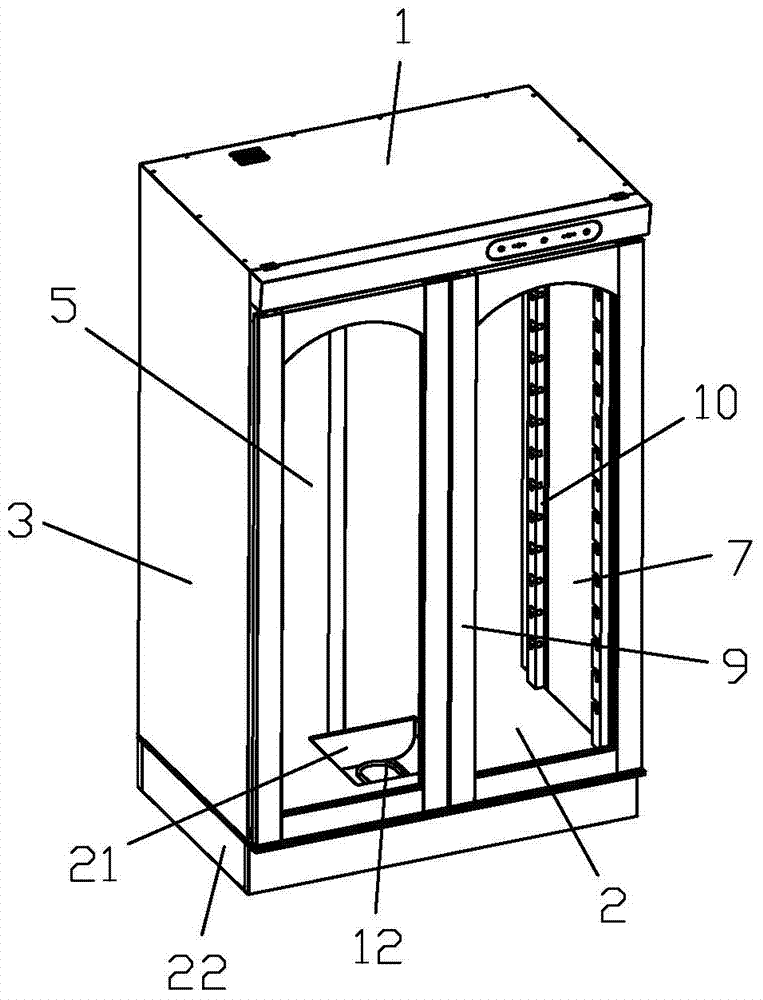

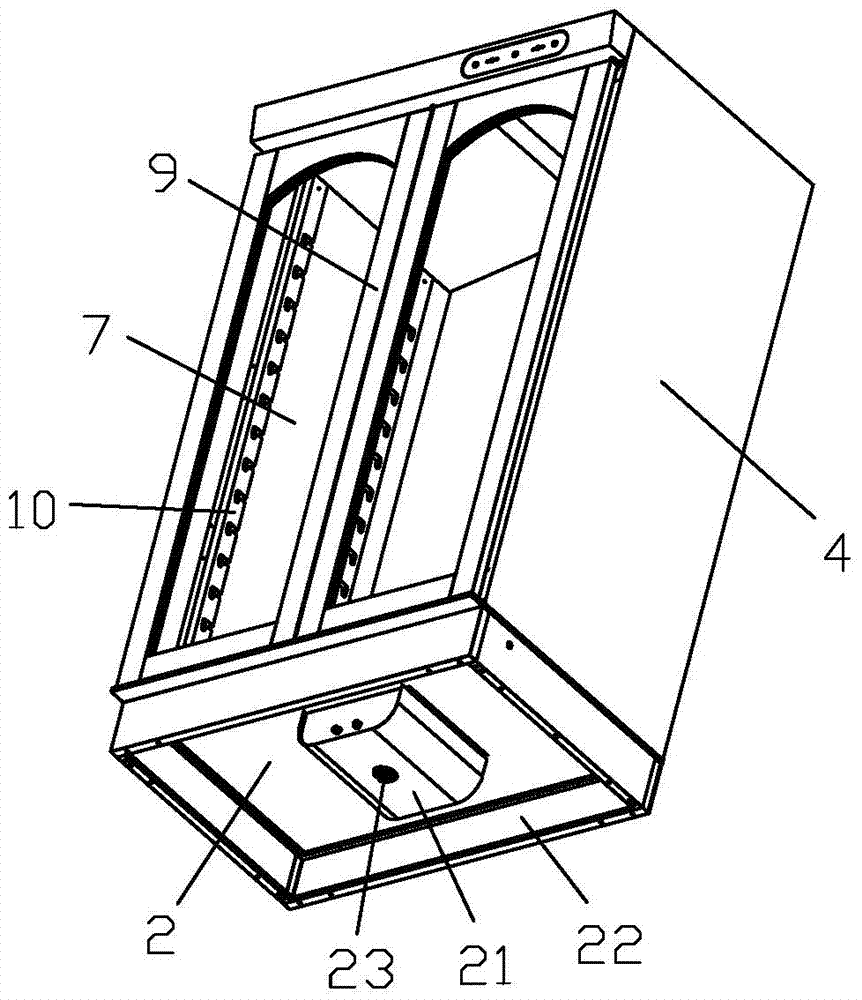

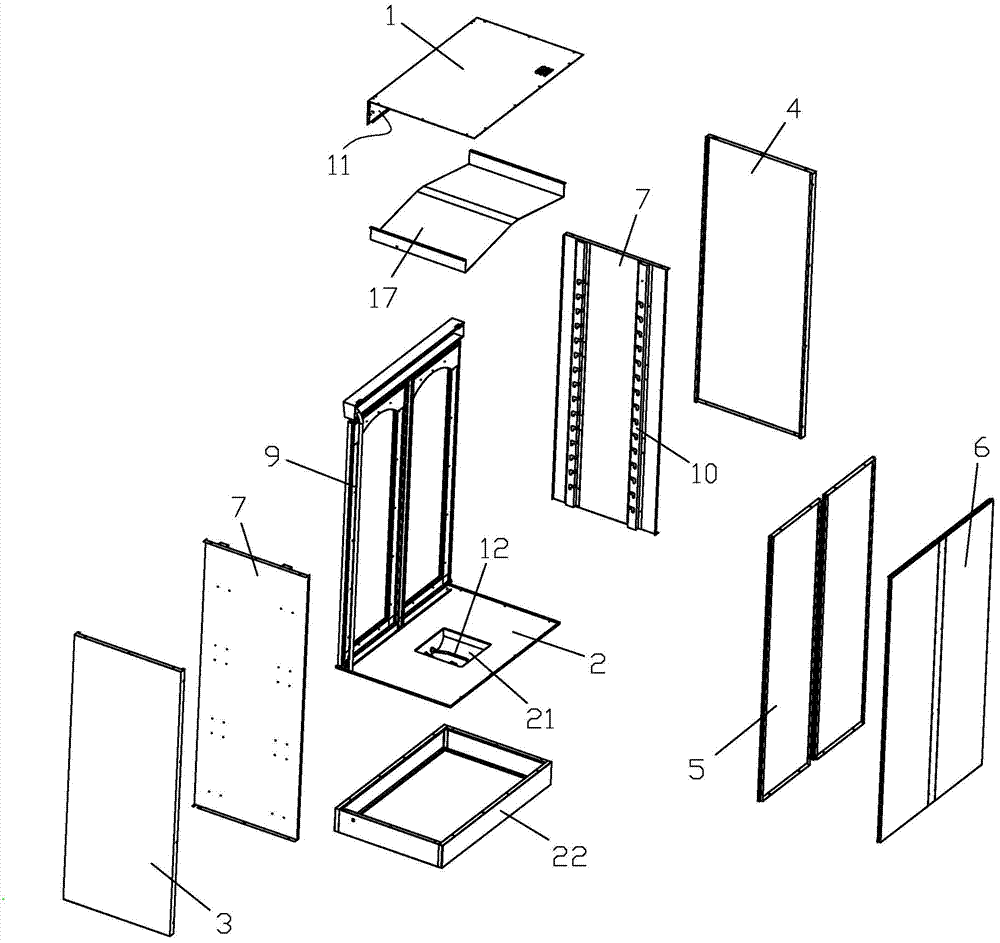

[0015] refer to Figure 1~Figure 5 , the split fermentation cabinet of the present invention comprises a top plate 1, a bottom plate 2, a left side plate 3, a right side plate 4 and a back plate 5, steps 54 are formed on the left and right side walls of the back plate 5, and the left and right The rear walls of the side plates 3 and 4 are formed with flanges 41 overlapping the steps 54, the rear wall of the back plate 5 is attached to the first connecting plate 6, and the left and right sides of the first connecting plate 6 The side wall is formed with a first bent portion 61 that fits on the overlapping surface of the step 54 and the flange 41, and the upper and lower walls of the first connecting plate 6 are bent forward to form a joint that overlaps the upper and lower sides of the back plate 5, respectively. The second bending portion 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com