Modular Fault Tolerant Flux Switching Permanent Magnet Linear Motor Control Method

A permanent magnet linear motor and magnetic flux switching technology, which is applied in electronically commutated motor control, motor control, motor generator control, etc., can solve problems such as fault-tolerant performance limitations, achieve high power, strong ability to operate with faults, and control Simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below according to the drawings and specific embodiments of the specification.

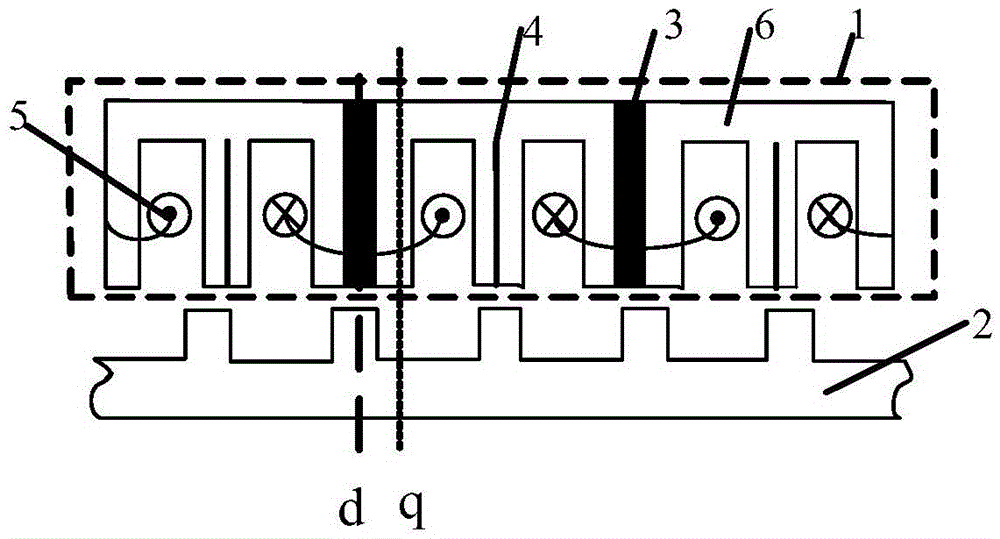

[0035] Such as figure 1 As shown, the modular fault-tolerant magnetic flux switching permanent magnet linear motor includes primary teeth 1 and secondary teeth 2, and the primary and secondary teeth 2 both adopt a salient pole structure, and the primary teeth 1 include eight pieces of permanent magnets. Magnet 3, armature winding 5 and seven fault-tolerant "Ш"-shaped magnetic permeable modules 6, said "Ш"-shaped permeable magnetic modules 6 include fault-tolerant teeth 4 and magnetically permeable iron cores, and said magnetically permeable cores are side by side horizontally placed, the magnetically permeable iron core is provided with fault-tolerant teeth 4, the permanent magnets 3 are tangentially alternately magnetized, and each piece of permanent magnet 3 is embedded in two adjacent "Ш"-shaped magnetically conductive Between the modules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com