Fault diagnosis method, fault-tolerant control method and fault-tolerant control system of BLDC position sensor

A sensor fault, fault diagnosis technology, applied in the direction of a single motor speed/torque control, instruments, measuring devices, etc., can solve problems such as torque ripple and motor current drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

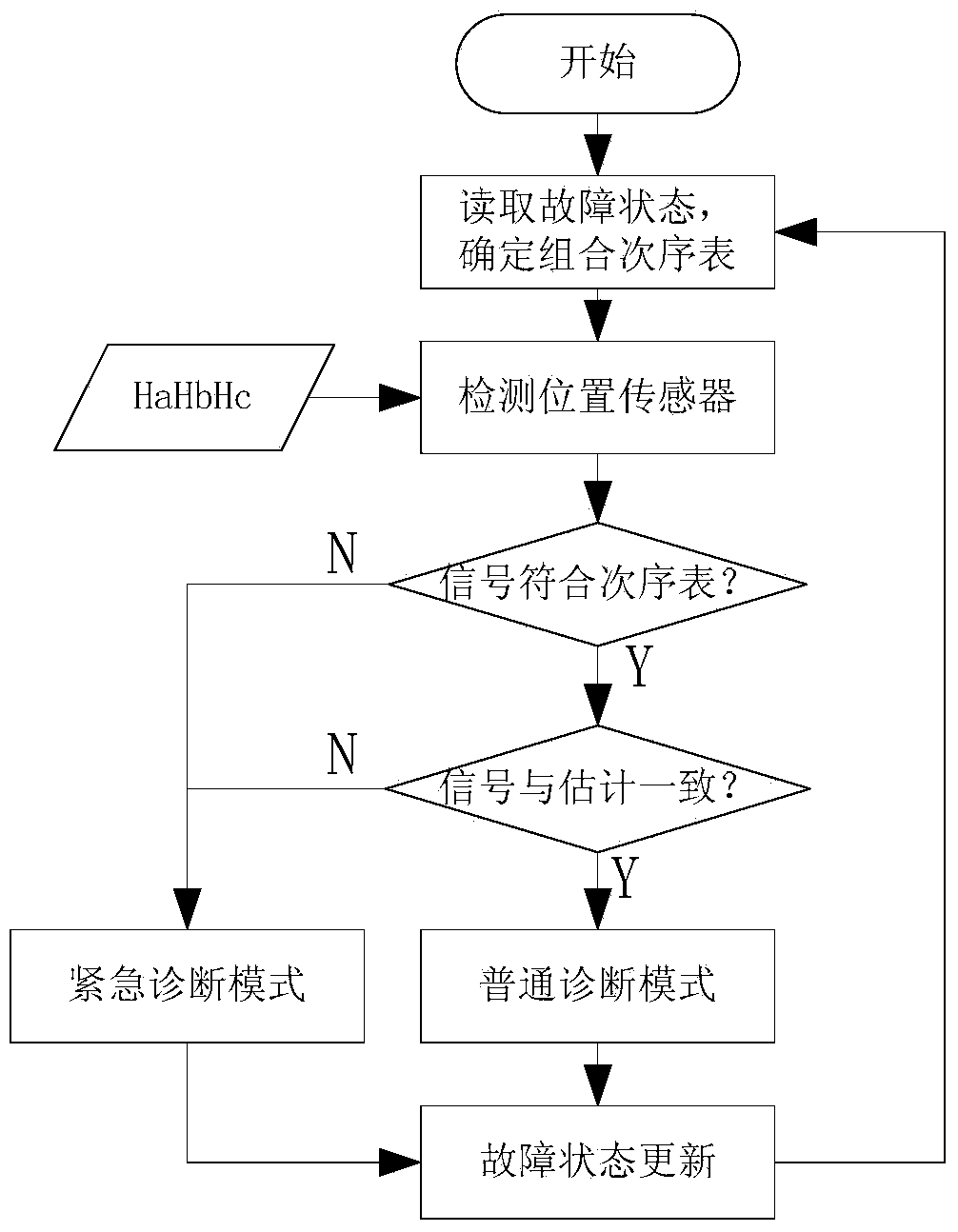

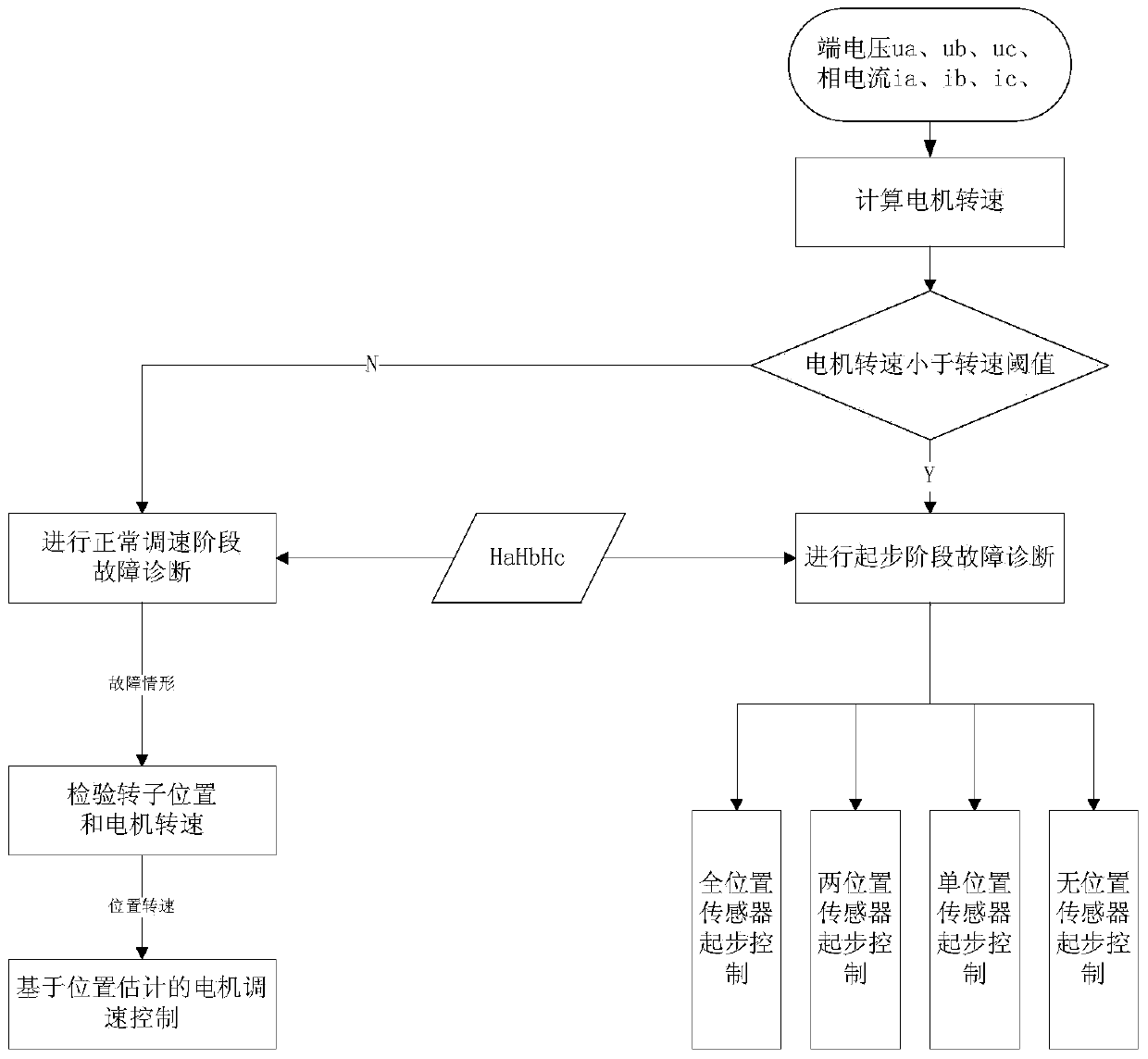

[0068] The invention proposes a fault diagnosis method for a position sensor of a brushless DC motor for a vehicle, a fault-tolerant control method based on fault diagnosis of the position sensor and a fault-tolerant control system thereof. The control method performs fault-tolerant control on the operation of the motor according to the fault state of the position sensor, so as to avoid the adverse effect of the fault of the position sensor on the operation of the motor.

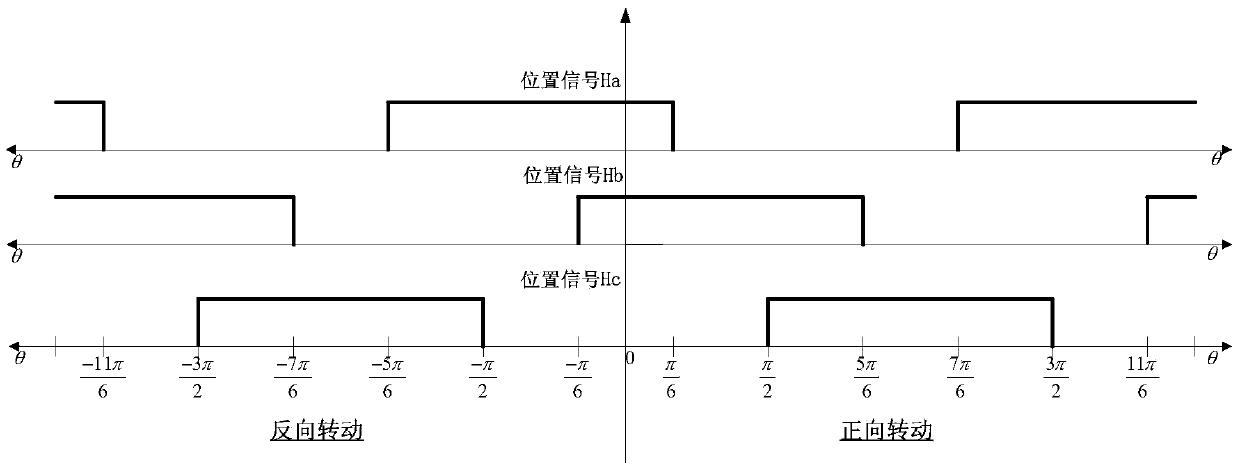

[0069] Generally, a brushless DC motor (BLDC) has three Hall sensors as position sensors and obtains rotor position information from them. According to the particularity of the control process, the brushless DC motor control process includes start control and normal speed control. When the rotor speed is higher than a certain speed threshold, the motor enters the normal spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com