Condenser cleaning system and cleaning method in steam turbine closed type circulating water system

A closed-cycle, steam turbine technology, applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., can solve the problems of unsatisfactory state, low cleaning coefficient, increased back pressure, etc. Good cleaning effect and the effect of reducing the amount of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

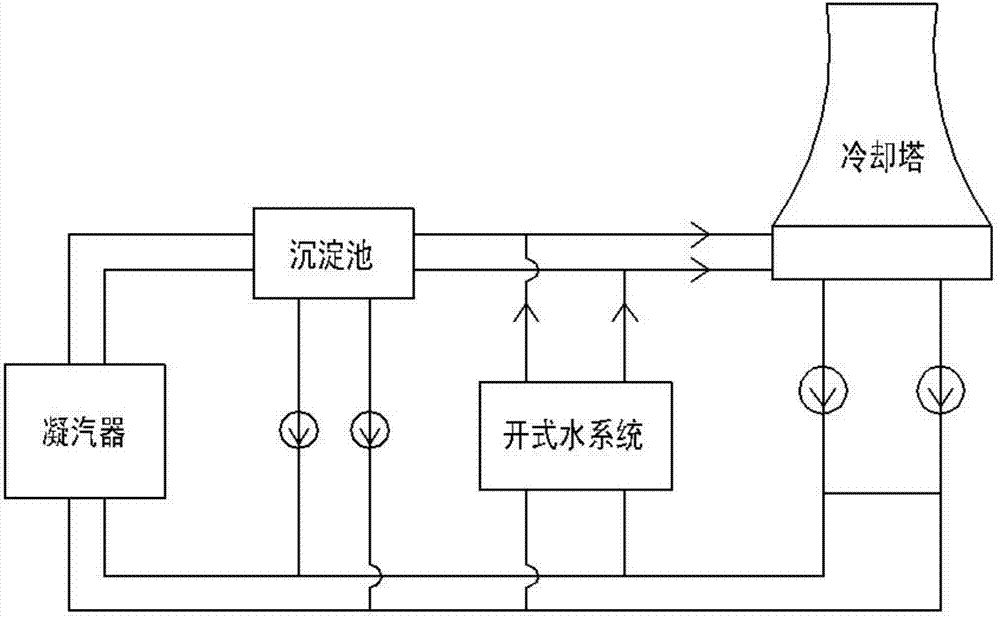

[0028] see figure 1 , the structure of the condenser cleaning system in the closed circulating water system of the steam turbine in this embodiment is set as:

[0029] For the steam turbine closed circulating water system consisting of a cooling tower, a condenser and an open water system, a sedimentation tank is installed at the outlet of the condenser, and the effluent of the sedimentation tank and the effluent of the open water system enter the cooling tower together. The solid particles discharged at the bottom of the sedimentation tank re-enter the condenser from the water inlet of the condenser; the solid particles have a density of 1-2g / cm 3 For high-quality ceramsite sand, the particle size of ceramsite sand is selected to be 0.5-5mm, which is smaller than the diameter of the filter holes in the circulating water system of the steam turbine.

[0030] The cleaning method of the condenser in the steam turbine closed circulating water system in the present embodiment is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com