Four-channel rotating jacket

A four-channel, rotating clamp technology, applied in the field of heat exchange, can solve the problems of low flow rate, low heat exchange efficiency, easy to short-circuit, etc., and achieve the effect of consistent temperature field and consistent flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

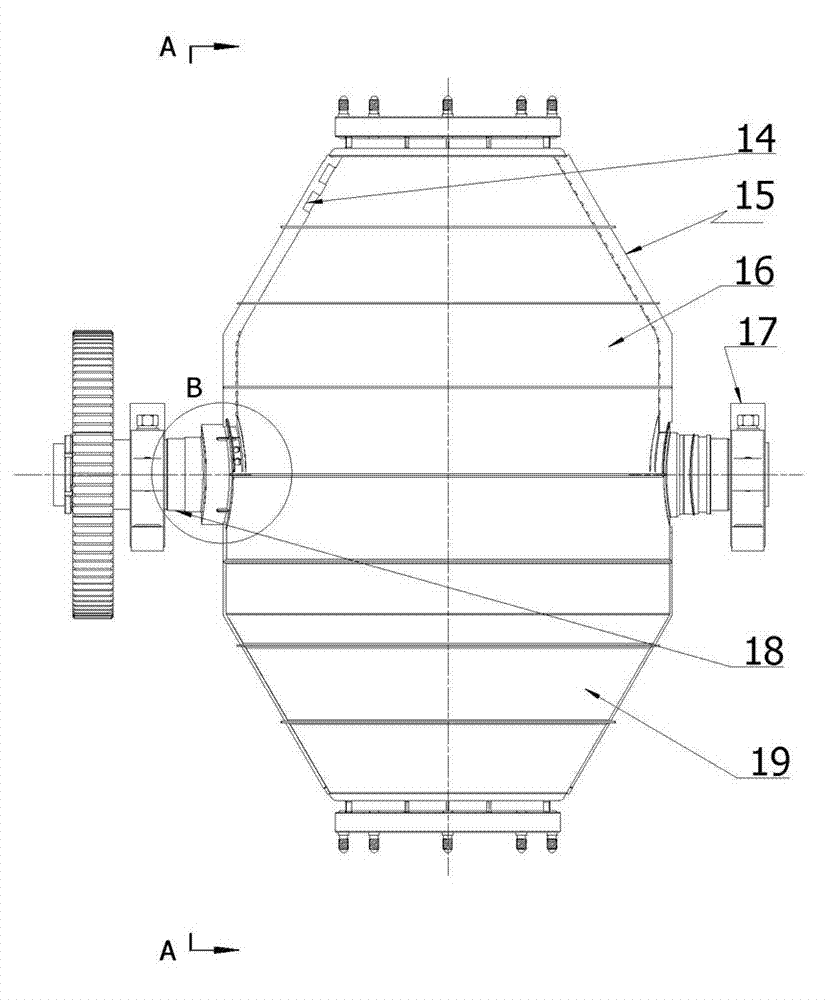

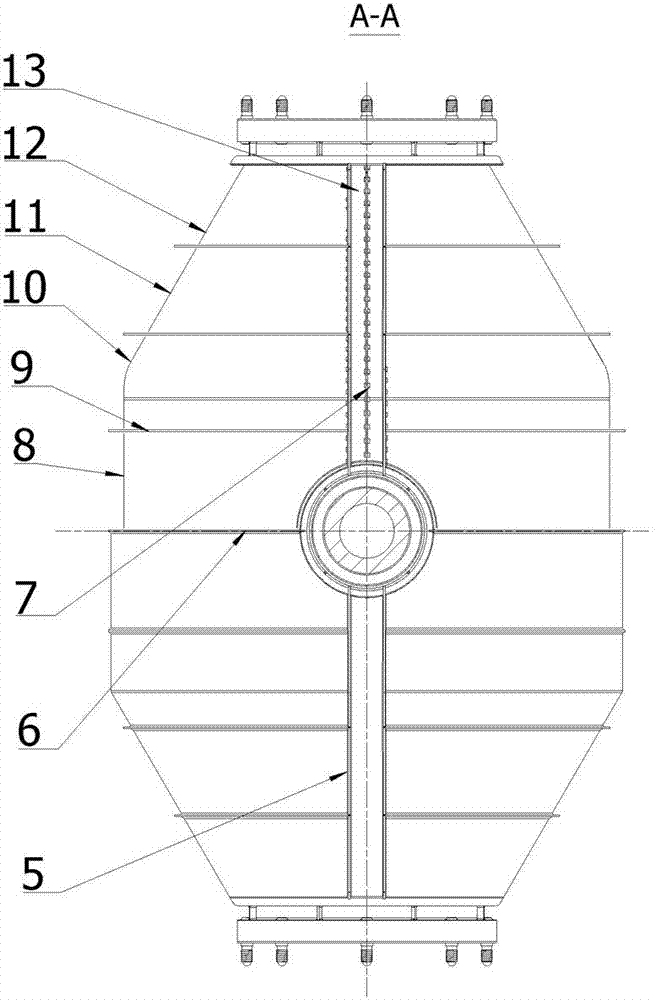

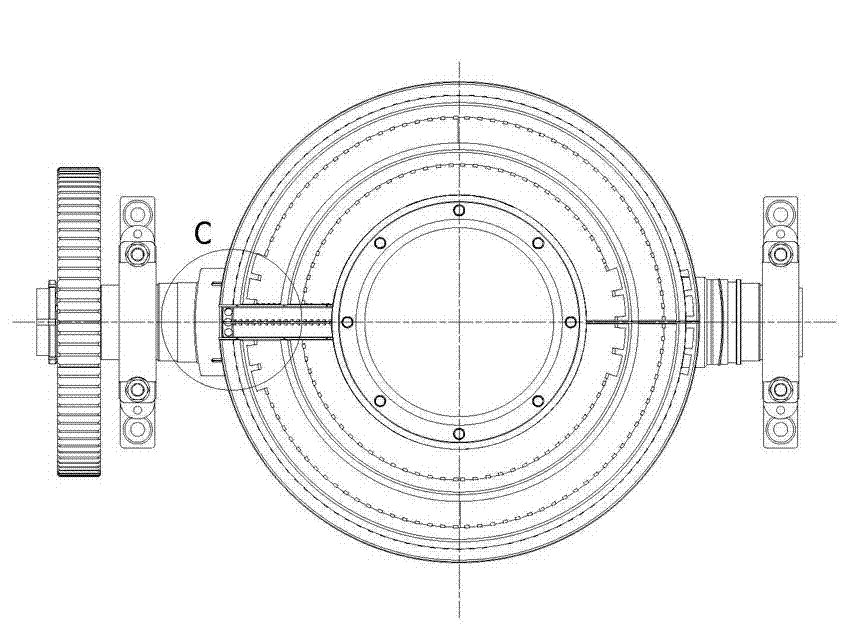

[0012] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention is based on the hollow rotating shaft 18, the jacket 19, the cylinder 16, and the bearing seat 17. The present invention is that the heat exchange fluid medium enters from the hollow rotating shaft 18, and the jacket of the four-channel water-distributing ring 4 The water inlet 3 enters the flow channel in the jacket, and the horizontal channel partition 6 divides the geometrically symmetrical biconical jacket 19 into two symmetrical areas. The plate 15 divides each zone into two channels. The horizontal flow channel partition 9 and the backwater longitudinal partition 5 are provided with flow channel openings 1 and 14, and the heat exchange fluid medium in each flow channel flows through the flow channel openings. , enter the four-channel water distribution ring 4 from the jacket return port 2, and return to the hollow rotating shaft 18 to flow out.

[0013] The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com