Method and equipment for synthesizing polycrystal of phosphor, germanium and zinc

A synthesis method and polycrystalline technology are applied in the field of preparation of ternary compound semiconductor materials, which can solve the problems of high vapor pressure, explosion of crucibles, inability to meet the requirements of ZGP single crystal growth and device fabrication, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Crucible for synthesis

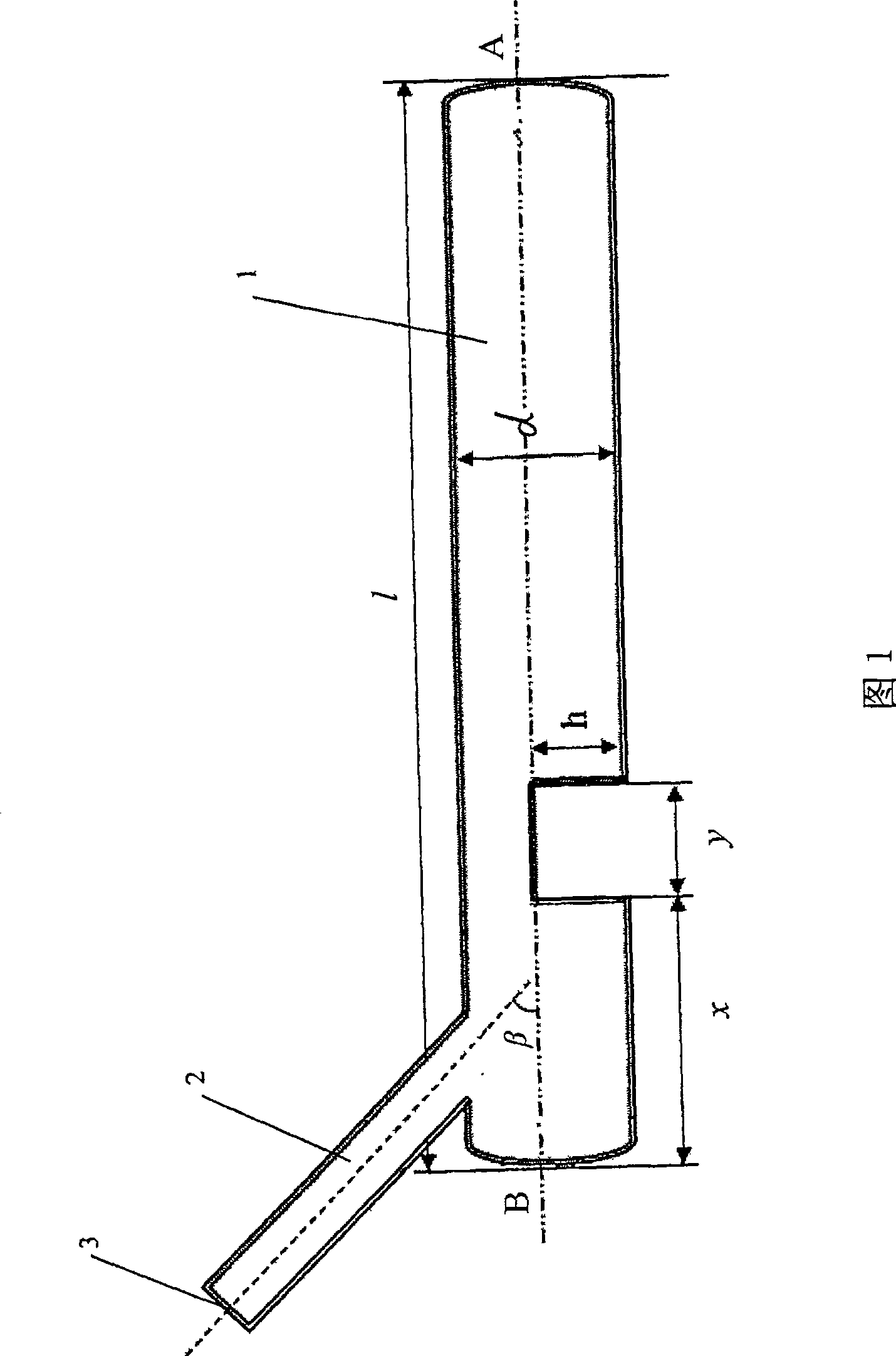

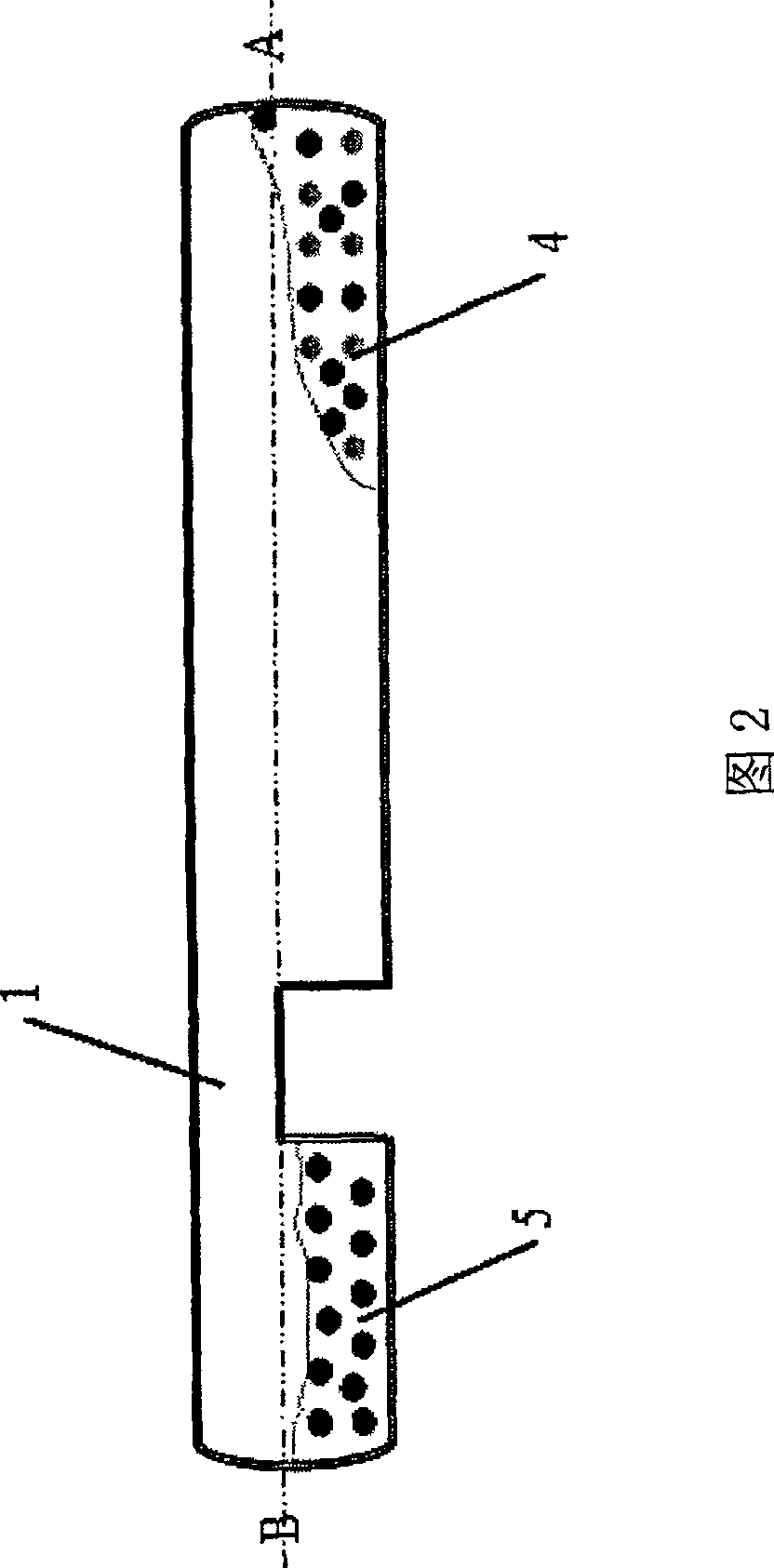

[0034] In this embodiment, the shape and structure of the crucible for synthesis are shown in Figure 1, which consists of a main body 1 and a feeding tube 2. The main body 1 is a quartz glass tube with an inner diameter of 28 mm and a length of 400 mm and closed at both ends. One end is A, The other end is B, a groove is arranged at a length of 45mm from the end of the body B, the length y of the groove is 25mm, the depth h is 1 / 2 of the inner diameter d, and the feed pipe 2 intersects at a distance of In the section with a length of 45mm at the end of the B end of the body, the feed port 3 is opposite to the groove notch, the angle β between the axis and the axis of the body is 60°, and the material is quartz glass.

Embodiment 2

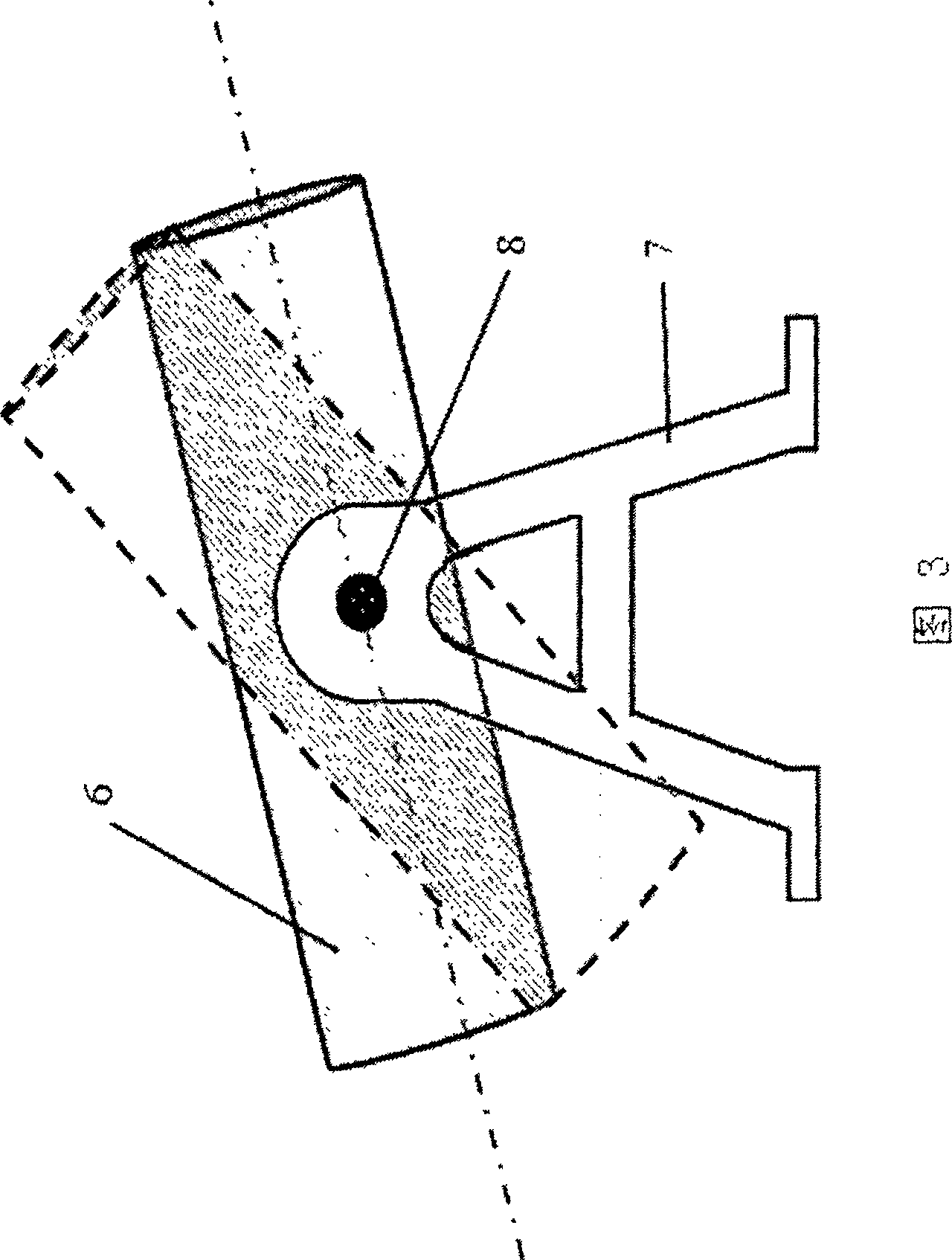

[0035] Example 2: Two-temperature zone tube furnace for synthesis

[0036]In this embodiment, the structure of the two-temperature zone tube furnace for synthesis is shown in Figures 3 and 4, including a furnace body 6, a heating element 9 mounted on the furnace body, a bracket 7 hinged to the furnace body through a hinge 8, Explosion-proof monitoring thermocouple 10, low temperature area temperature control thermocouple 11, high temperature area temperature control thermocouple 12, monitoring temperature controller 13, low temperature area heating temperature controller 14, high temperature area heating temperature controller 15 and explosion-proof temperature automatic controller . The above components are assembled as follows:

[0037] The heating elements 9 are distributed along the axial direction of the furnace body and are connected into two groups of independent heating systems, one group of heating systems provides heat for the low-temperature area of the furnace, ...

Embodiment 3

[0049] Example 3: Synthetic method

[0050] In this embodiment, the raw materials used are zinc (Zn), germanium (Ge), and phosphorus (P), all of which are of 6N grade. When batching, the molar ratio of each raw material is zinc:germanium:phosphorus=1:1:2. According to the above Proper proportion of phosphorus-rich ingredients: zinc 8.87481 grams, germanium 9.85581 grams, phosphorus 8.41137 grams. The crucible used in the synthesis is the crucible described in Example 1; the tube furnace used in the synthesis is

[0051] Example 2 The two-temperature zone tube furnace.

[0052] The synthetic process steps are as follows:

[0053] 1. Crucible cleaning and drying

[0054] After soaking and rinsing the inner wall of the crucible with tap water, inject hydrofluoric acid lotion for 3-5 minutes, then rinse with tap water until neutral, place it in an ultrasonic cleaning tank for 8-10 minutes, and then repeat with high-resistance deionized water. Just rinse off. Drain the cleaned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com