Biomass particle burner of cylinder-type feeding system

A biomass particle and feeding system technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of easy life of stuck materials, low feeding efficiency, etc., and achieve non-wear, high feeding efficiency, and failure rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

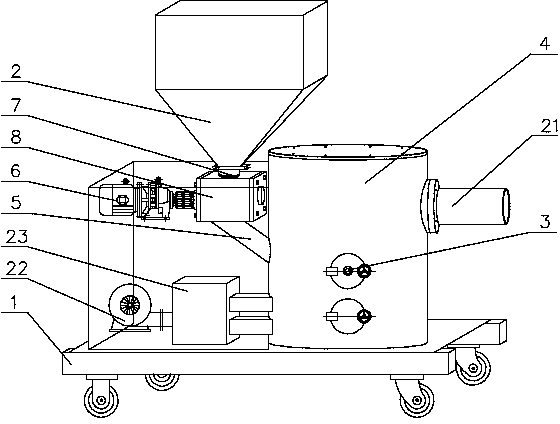

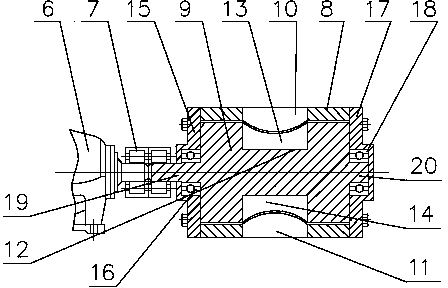

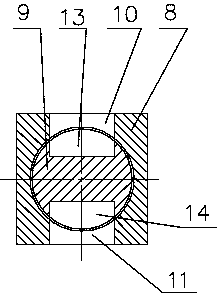

[0018] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0019] As shown in the figure, a biomass particle burner with a cylindrical feeding system includes a frame 1, a hopper 2, a feeding mechanism, a combustion chamber 4 and a feeding pipe 5, and the hopper 2 passes through the feeding mechanism and the feeding pipe 5 connected, the feeding pipe 5 communicates with the combustion chamber 4, the feeding mechanism includes a motor 6, a feeder and a transmission member 7, the feeder includes a housing 8, a conveying body 9, and the housing 8 is fixed on the feeding pipe 5 Above, the conveying body 9 is a cylinder and is located inside the shell, the motor 6 drives the conveying body 9 to rotate circumferentially through the transmission member 7, and the shell 8 is provided with feeding holes separated by a certain distance 10 and discharge hole 11, the feed hole 10 communicates with the hopper 2, the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com