Connecting piece with cavity sectional material

A technology of connecting parts and cavities, applied in building components, windows/doors, buildings, etc., can solve problems such as unsatisfactory waterproof performance, large water seepage gaps, and weak connections, achieving good reinforcement effect, increasing connection area, Good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

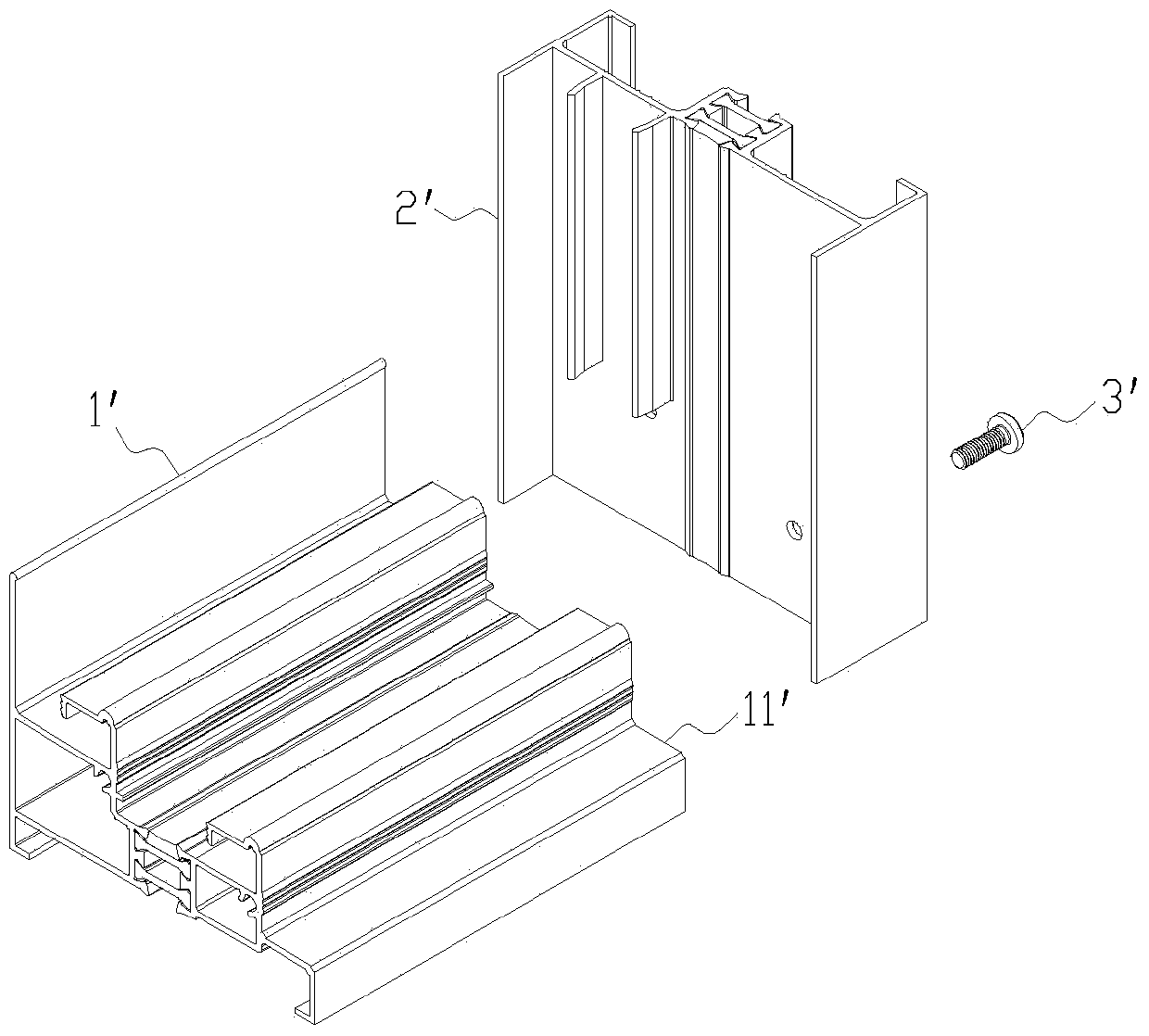

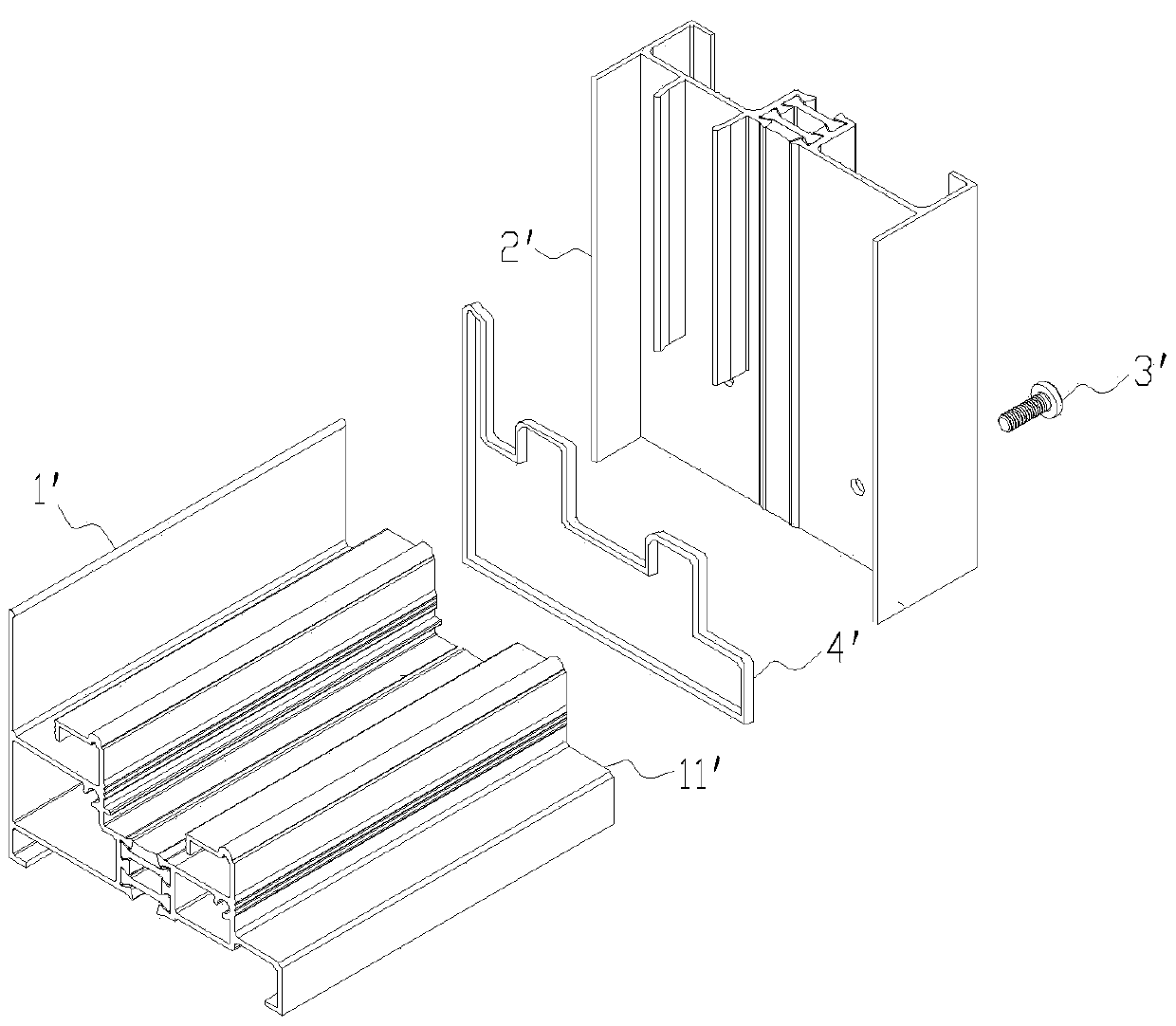

[0033] Such as image 3 , Figure 4 A connection piece with a cavity profile is shown, which is used for the connection between the metal horizontal profile 1 (such as the sliding of the door and window, the lower middle waist) and the metal vertical profile 2 (such as: the frame of the door and window), the horizontal profile 1 A cavity with a sealed section is provided along the length direction.

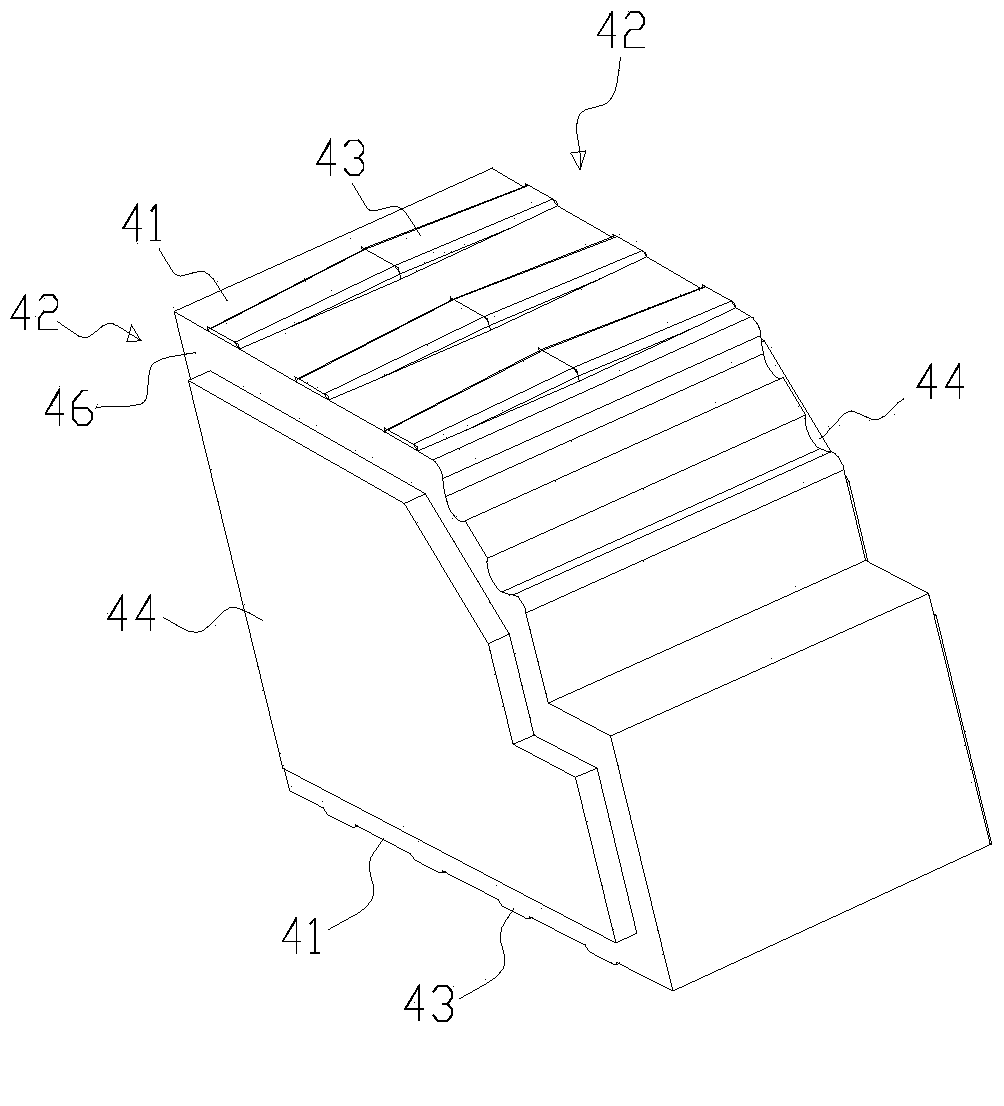

[0034] The connecting piece is a block-shaped plastic hollow piece whose outer contour is adapted to the cavity so as to be embedded in the cavity. It includes upper and lower two insertion surfaces 41 and two insertion surfaces perpendicular The bonding surface 42 of 41, described bonding surface 42 is made up of inner end face and outer end face, all forms boss 44 on inner end face, outer end face, and the height of boss 44 is 1cm, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com