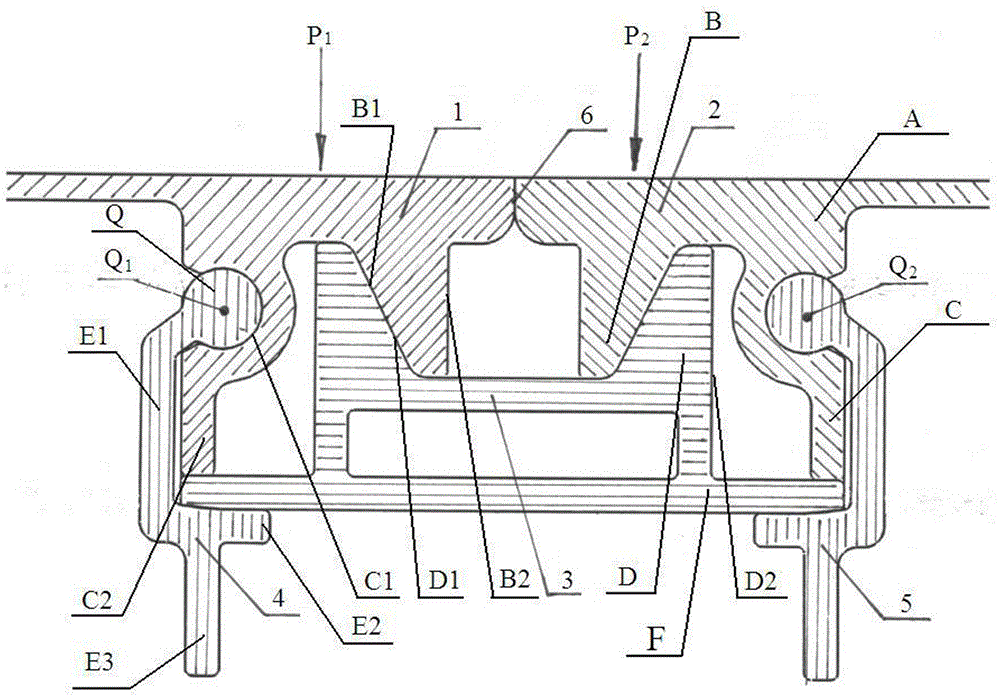

A composite structure aluminum alloy formwork

A technology of aluminum alloy formwork and combined structure, which is applied in the direction of formwork/formwork components, building structures, and on-site preparation of building components, which can solve the problems of short service life of formwork, high cost, and poor sealing joints, and achieve Improve construction efficiency, prolong service life, and achieve good sealing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

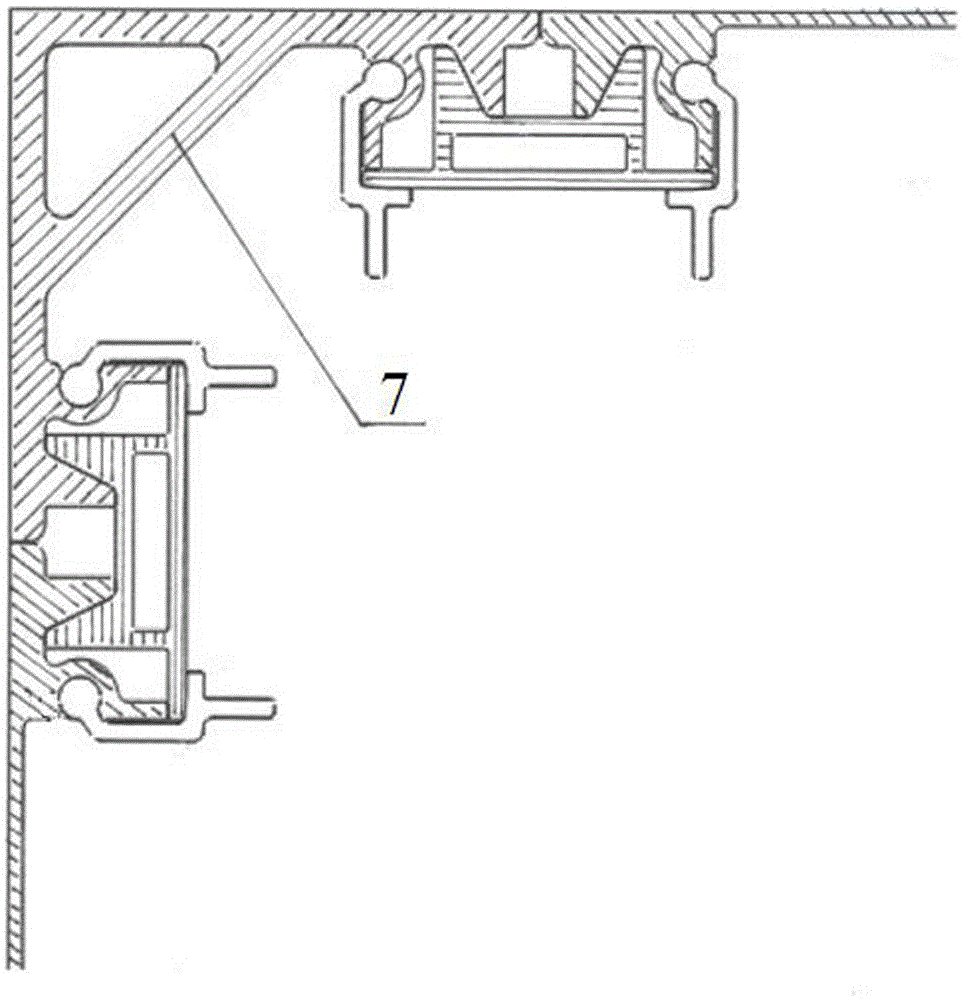

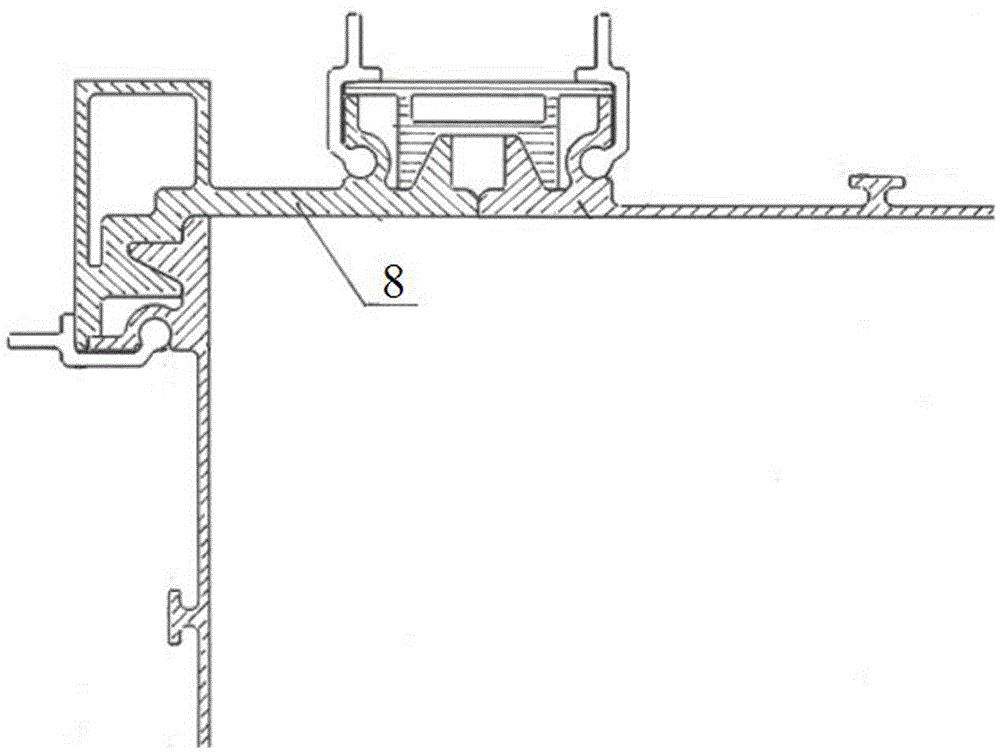

Method used

Image

Examples

Embodiment

[0047] Example: Public rental housing project in a district of Kunming

[0048] (1) Project features: The public rental housing designed by this project includes single-living, small-sized and medium-sized houses, with an area ranging from 37m2 2 to 55m 2 , a number of 35-story high-rise buildings with a building height of 2.7m and a frame shear wall structure. In order to reduce the construction cost, the concrete is required to reach the level of no plastering after pouring, so higher requirements are put forward for the building formwork system. According to the characteristics of the project, it is appropriate to choose an aluminum alloy formwork system with outstanding advantages.

[0049] (2) Profile production: Utilizing the technical solution proposed by the present invention, first design various aluminum alloy profiles required by the formwork composition system, and entrust aluminum alloy profile factories to open molds to produce the required profiles.

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com