Method for construction of diameter-expanding pile on pile top

A construction method and technology of expanding diameter piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as thick and unfavorable sediment at the bottom of holes, and failure to meet the construction accuracy requirements of ultra-deep cast-in-situ piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

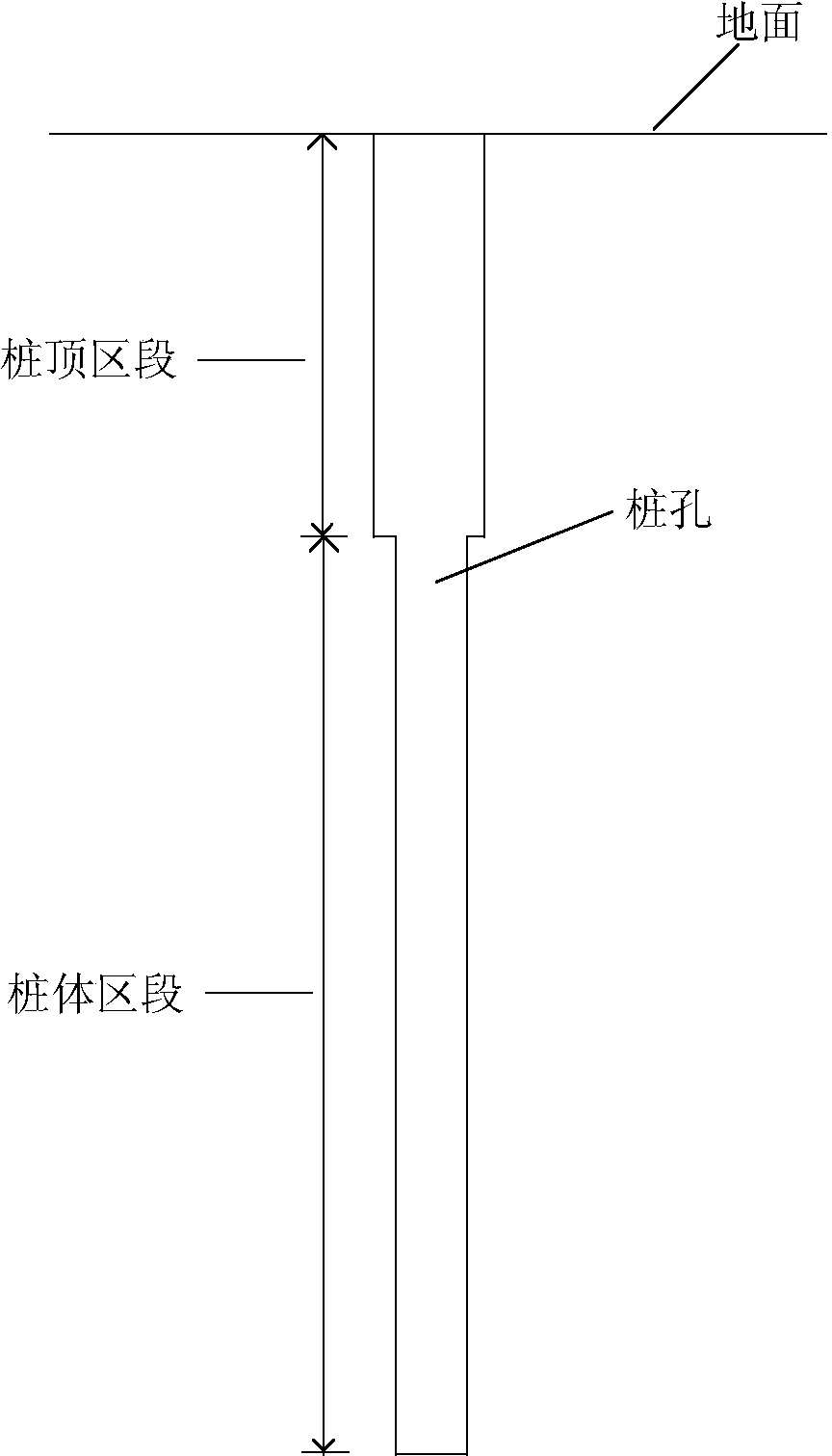

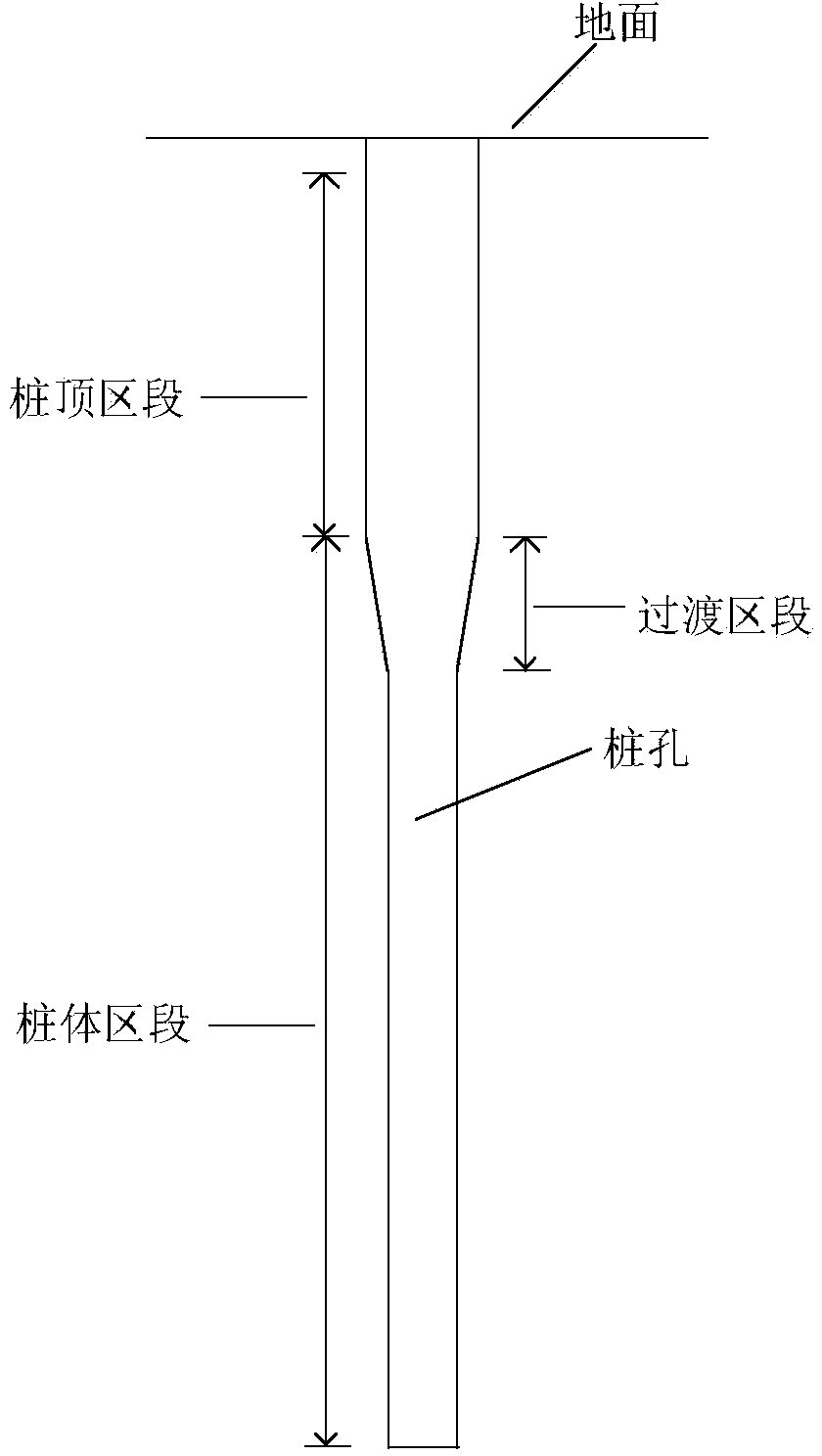

[0026] The following will combine Figure 1 to Figure 5 The construction method of the pile top diameter expansion pile provided by the present invention is described in detail, which is an optional embodiment of the present invention, and it can be considered that those skilled in the art can implement it within the scope of not changing the spirit and content of the present invention. Modify and polish.

[0027] The present embodiment provides a method for constructing pile top diameter-expanding piles, which includes the following steps in turn:

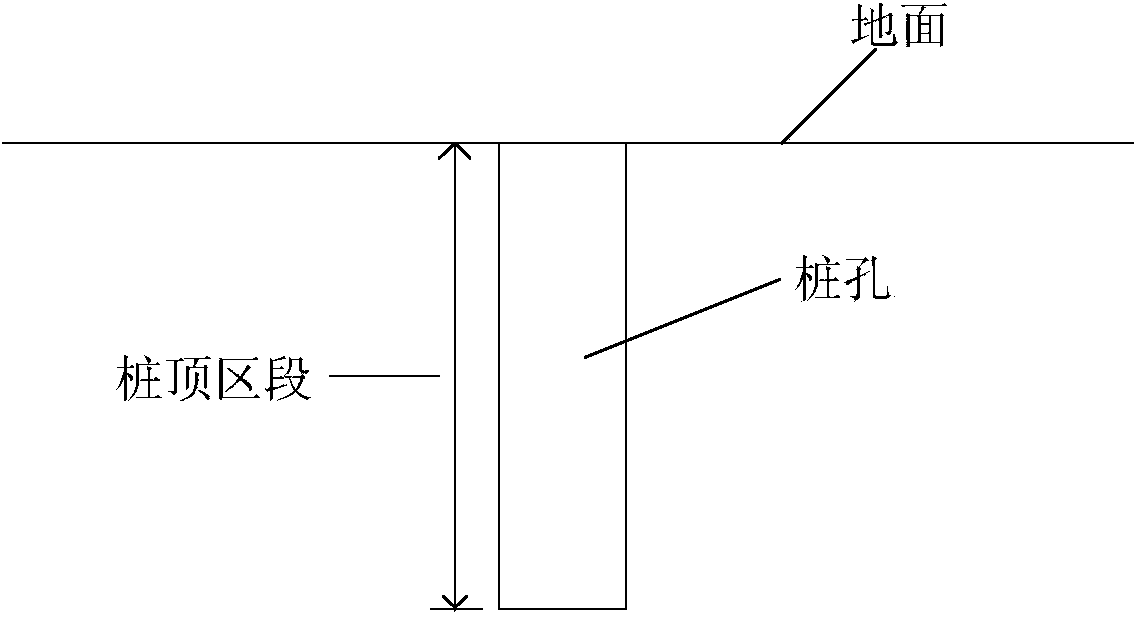

[0028] S10: Please refer to figure 1 , the rotary drilling rig is equipped with a large-diameter drill bit and then drilled on the ground to form an enlarged pile top section. At this time, the pile hole only includes the pile top section; in this step, drill from the ground to the variable section At the upper edge of the pile, this position matches the reinforcement cage made separately, and it can also be considered as the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com