A multi-degree-of-freedom powder feeding device

A technology of powder feeding device and degree of freedom, applied in metal material coating process, coating, etc., can solve problems such as difficult to achieve continuous adjustment, blockage of powder feeding nozzle, fixed dead, etc., to achieve portability and adaptability Strong, easy to operate, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] In order to overcome the shortcomings of the existing laser cladding powder feeding device, that is, to adopt a suitable powder feeding principle and a good control device, the gravity powder feeding principle is adopted and on the basis of combining the advantages of mechanical principle technology and industrial computer program control technology, This embodiment provides a multi-degree-of-freedom powder feeding device, which can be transplanted to the output ends of various industrial lasers.

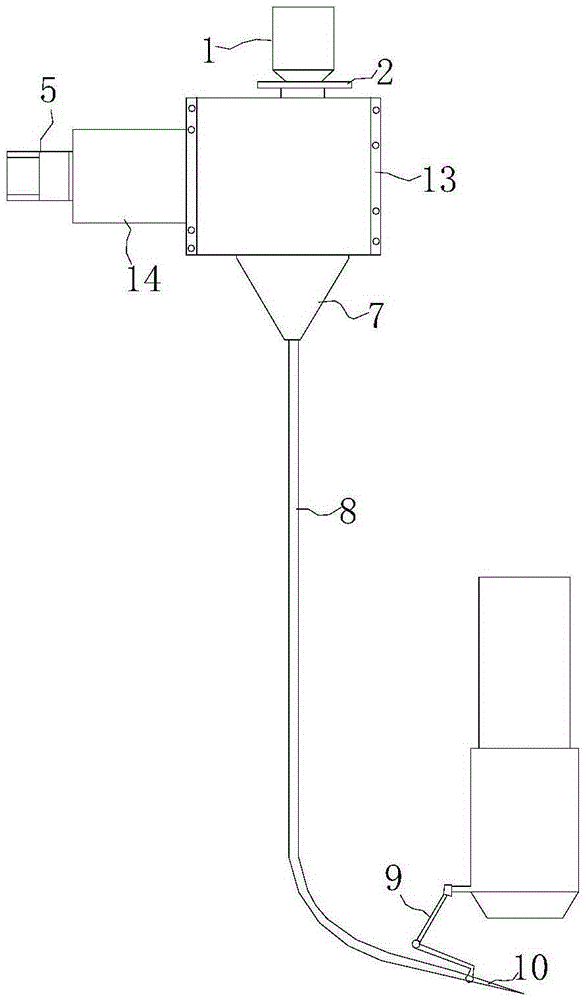

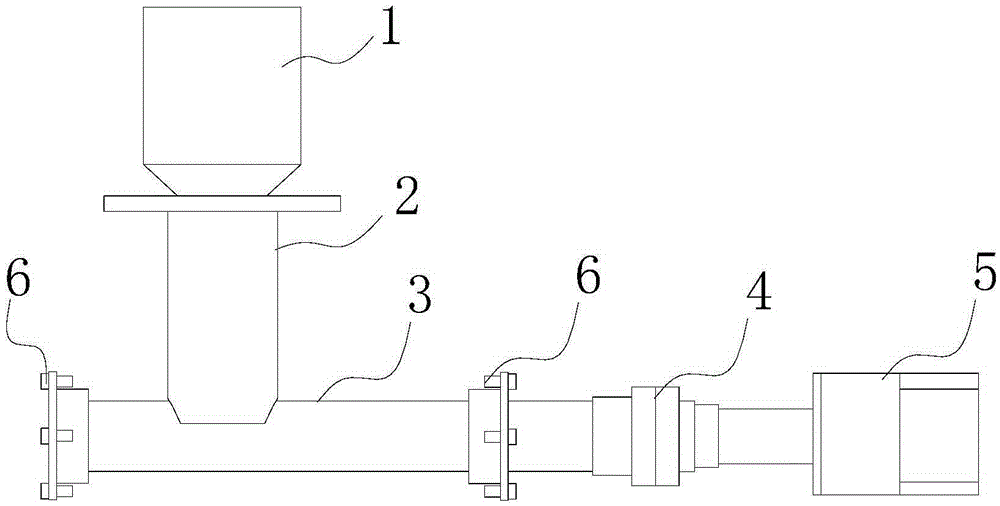

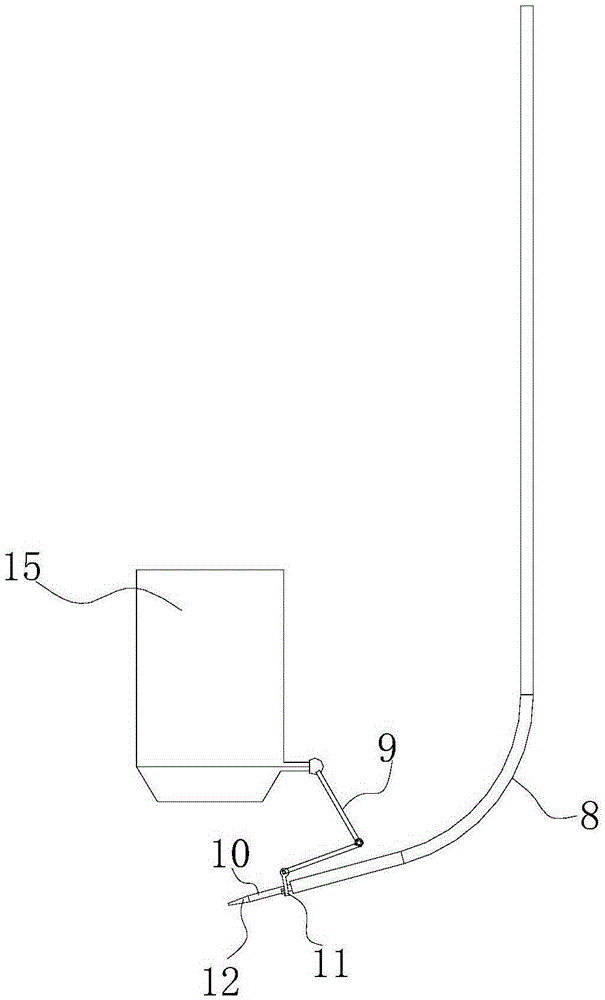

[0029] Such as Figure 1-Figure 2 As shown, the multi-degree-of-freedom powder feeding device provided by the present invention includes a powder holding funnel 1, a powder feeding shaft 2 arranged at the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com