Method for optimizing cracking depth of industrial ethane cracking furnace on line

A technology of ethylene cracking furnace and cracking depth, which is applied in the field of online optimization of cracking depth of industrial ethylene cracking furnace, which can solve the problems of manual determination, no cracking depth, lack of quantitative guidance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and embodiments.

[0029] This specific example is an optimization of the cracking of an industrial ethylene cracking furnace using naphtha as a raw material.

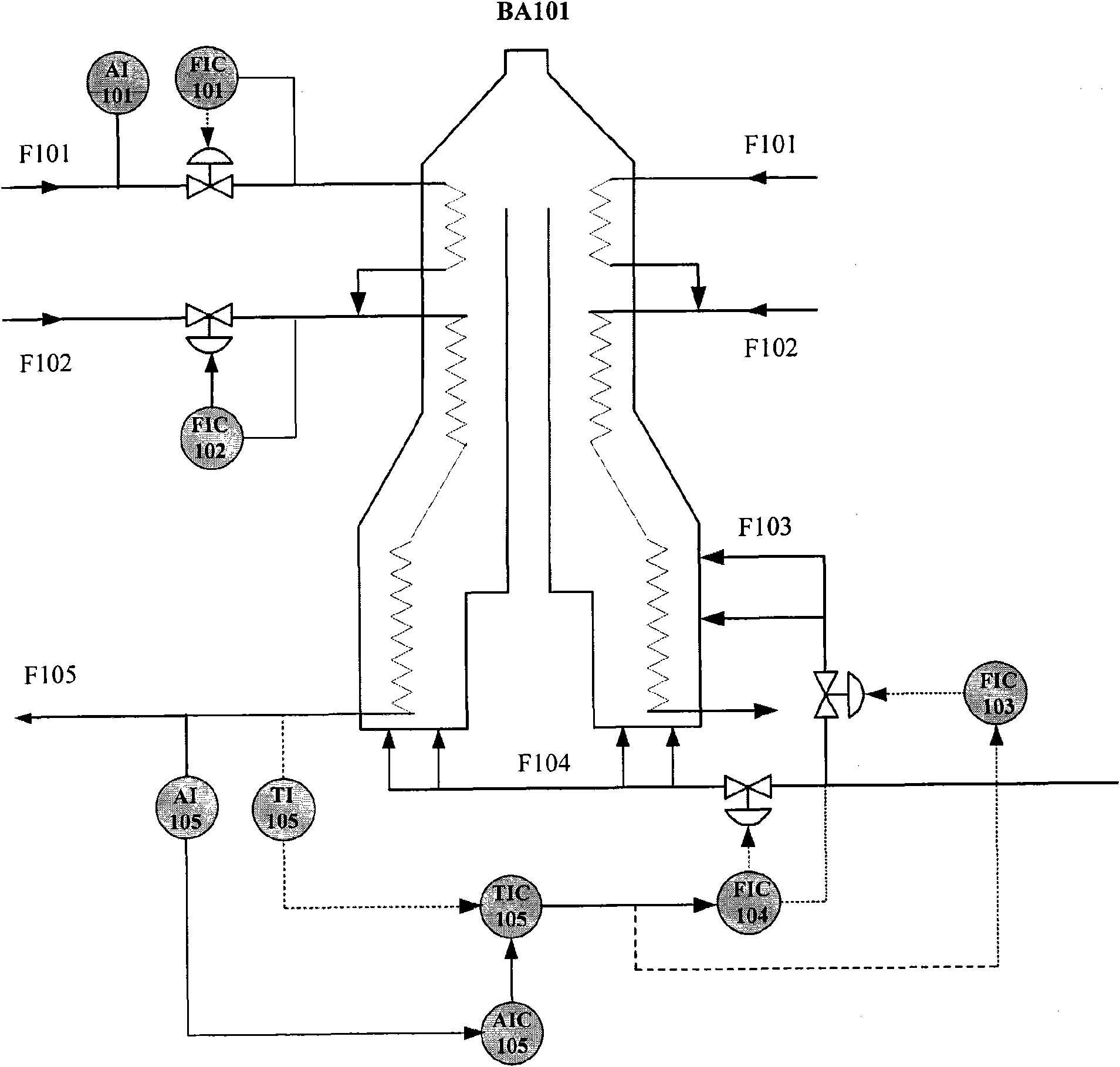

[0030] The industrial cracking furnace system of this specific example is figure 1 As shown, BA101 is a cracking furnace, including an upper convection section and a lower radiant section; F101, F102, F103, F104 and F105 are feed, steam, sidewall fuel gas, bottom fuel gas and cracked gas, respectively; FIC101, FIC102 , FIC103 and FIC104 are respectively the feed flow meter, steam flow meter, sidewall fuel gas flow meter, bottom fuel gas flow meter; AI101 is the raw material density meter, TI105, AI105 are respectively the cracking furnace outlet cracking gas temperature indicator and cracking gas Online analyzer, TIC105 is COT controller, AIC105 is cracking depth controller. figure 1 It includes a cascade control system composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com