In-situ chemical conditioning and vacuum preloading reduction method and conditioning device for landfill sludge

A chemical conditioning and sludge technology, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low processing capacity, low efficiency, and difficulty in using landfill sludge, so as to reduce costs and avoid secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

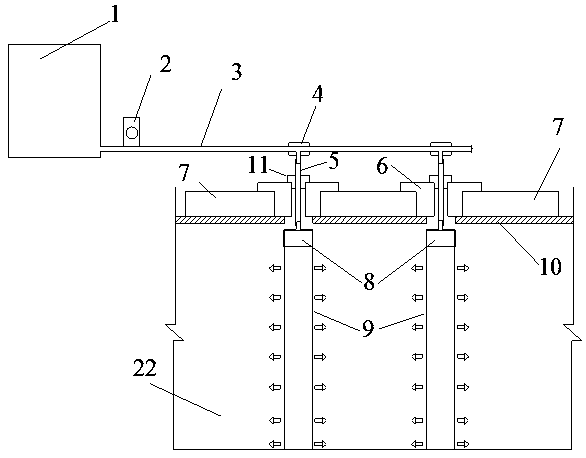

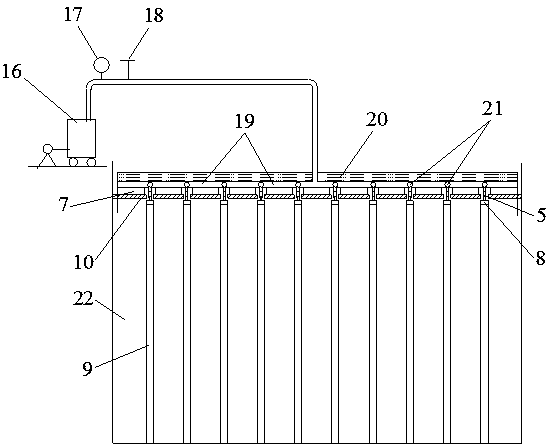

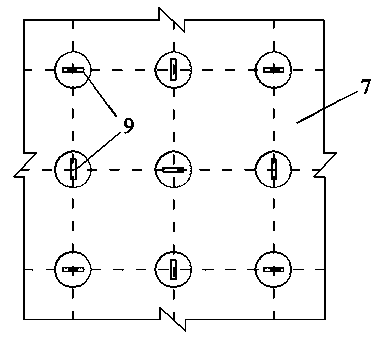

[0032] Such as figure 1 , image 3 , Figure 4 As shown, the bottom of the dissolving tank 1 of the present invention is connected to one end of the rubber tube 3 through the flow pump 2, and the other end of the rubber tube 3 is provided with a liquid outlet every 0.4m~0.6m, and each liquid outlet is respectively Install the perforated casing 4. Lay woven geotextiles 10 and high-strength foam boards 7 with multiple rows and columns of holes on the surface of the sludge landfill 22 from bottom to top, and connect plastic drainage board parts with the same structure to each hole casing 4; Each plastic drainage plate part comprises: plastic drainage plate 9, hand joint 8, connecting pipe 5 and stainless steel clip 12. One end of the connecting pipe 5 is connected to the nozzle of the hand joint 8, and the tank body of the hand joint 8 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com