Plastic tray

A pallet and plastic technology, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of spilling, easy tilting, uneven stacking of plastic pallets, etc., and achieve the effect of ensuring safety and avoiding tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

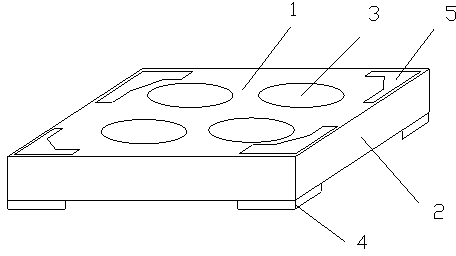

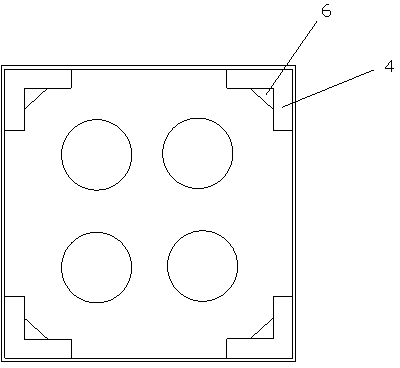

[0012] Such as figure 1 As shown, a plastic tray includes a tray body 1 and a support plate 2 integrally formed on the edge of the tray body 1, and a number of storage slots 3 are formed on the front side of the tray body 1. The shape of the storage slots 3 is consistent with the required The shape of the packaged product is suitable. On the inner surface of the corner of the support plate 2, an L-shaped bump 4 is integrally formed. The height of the L-shaped bump 4 is greater than the height of the support plate 2 and less than twice the height of the support plate. 2, the corners of the front of the tray body 1 are respectively recessed downwards and provided with L-shaped grooves 5 that are compatible with the L-shaped bumps 4, and the depth of the L-shaped grooves 5 is equal to the L-shaped bumps. Block 4 protrudes the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com