Suspension Mechanism for Additional Conductors of Catenary in Electrification of High Speed Railway

A high-speed railway and suspension mechanism technology, applied in the direction of overhead lines, etc., can solve the problems of insufficient strength, achieve the effects of flexible rotation, elimination of air gap discharge, and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

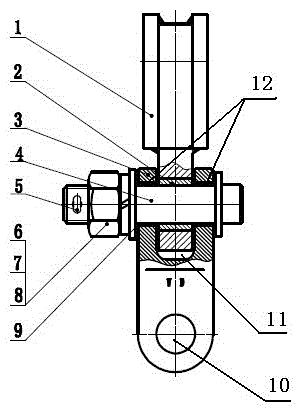

[0014] Such as figure 1 and figure 2 As shown, the additional wire suspension mechanism of the electrified catenary of high-speed railway is characterized in that: it includes a double-eared connecting plate 1 and a single and double-eared vertical connecting plate 3; both ends of the double-eared connecting plate 1 have double ears and two ear holes 13 and a first connection hole 14, the upper two ear holes 13 are respectively located on the two ears at both ends, the middle part of the ears is an empty groove and symmetrical to the left and right, the first connection hole 14 below is located on the line of symmetry, and the first connection 14 holes are inlaid with the second A bearing sleeve 2; the lower end of the single and double ear vertical connecting plate 3 has a second connecting hole 10, and the upper end has a U-shaped groove 11 perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com