Bloated brick perforation tool

A technology of bread bricks and tooling, which is applied in the field of bread brick punching tooling, which can solve the problems of mismatching through holes, inability to guarantee the accuracy of through holes of bread brick pressing blocks, secondary rework, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

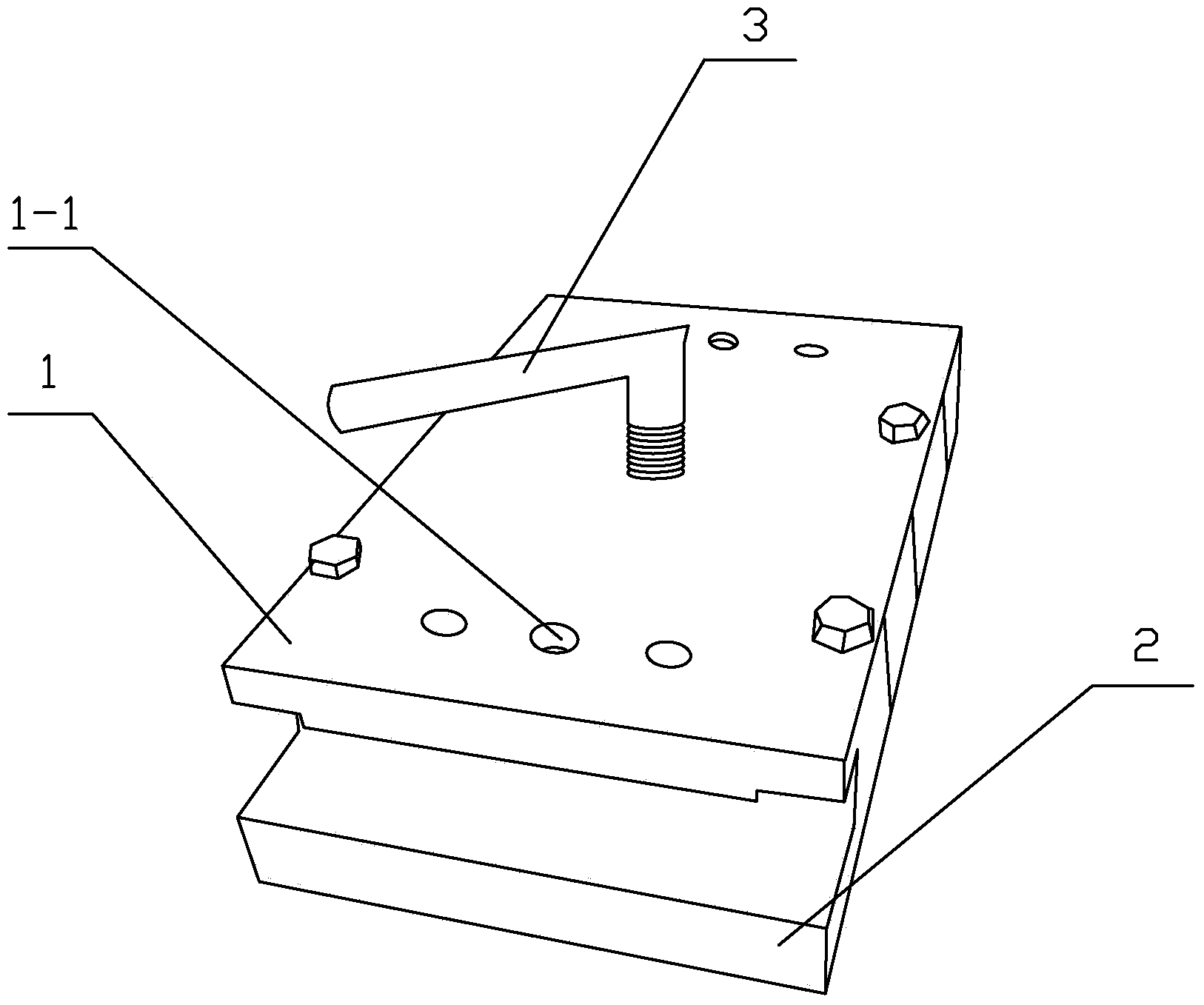

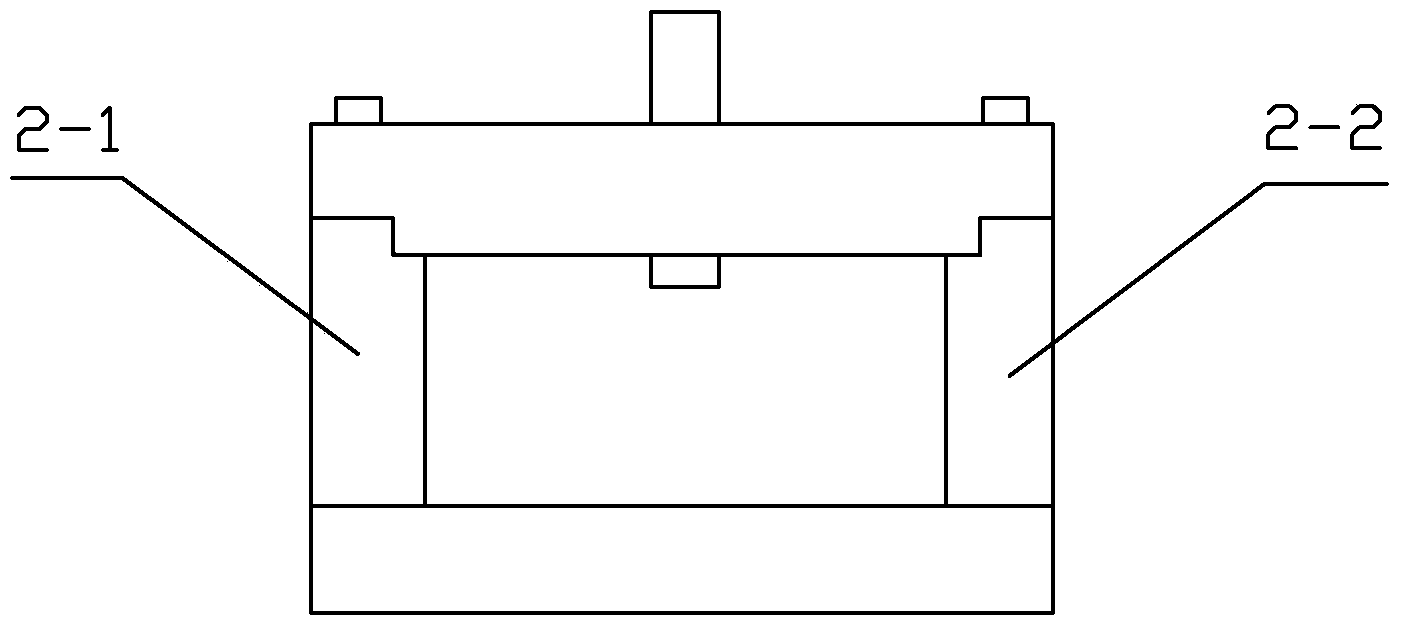

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a tool for punching bread bricks includes upper and lower pressing blocks 1 and 2 parallel to each other, and left and right baffles 2-1 and 2-2 are arranged on both sides of the lower pressing blocks. The upper pressing block and the left and right baffles are fixedly connected with the lower pressing block to form a semi-enclosed space. The semi-enclosed space matches the shape of the breadboard pressing block to be processed, so that the bread brick pressing block can slide freely in the semi-enclosed space . The upper briquetting block is provided with a drill form through hole 1-1, the position of the drill form through hole corresponds to the position of the mounting hole of the breadboard briquetting block to be processed, and the number of the drill form through holes in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com