Electrode structure of interlaced back contact (IBC) solar cell

A solar cell and electrode structure technology, applied in the field of solar photovoltaics, can solve the problems of cell efficiency drop, power loss, and 5-inch staggered back-contact cell technology, etc., to reduce losses, beautify the appearance, and improve photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

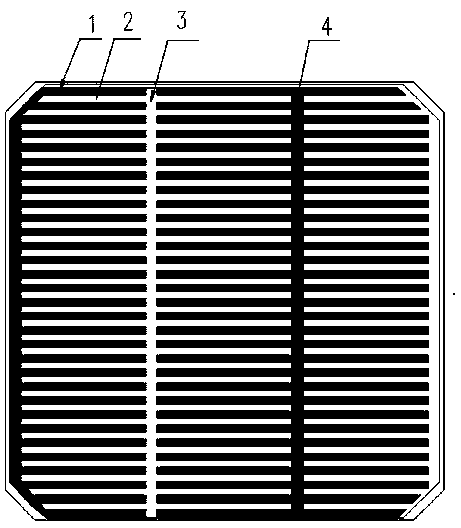

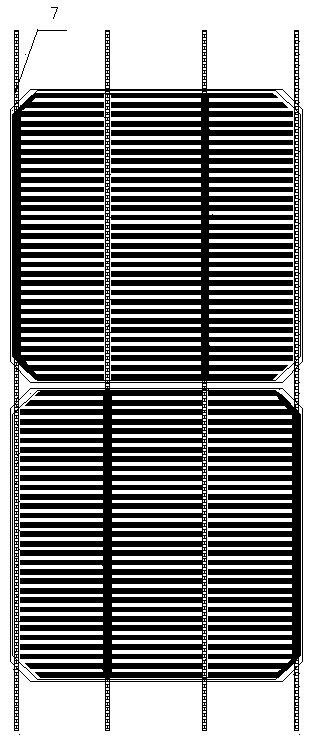

[0024] Embodiment 1, with reference to Figure 1-5 , a staggered back contact IBC solar cell electrode structure, the back of the cell is provided with interdigitated positive and negative grid electrodes (1, 2); the positive and negative grid electrodes (1, 2) pass through Insulation by laser etching or insulating glue; all the positive and negative grid electrodes (1, 2) on the back are respectively gathered on the strip or block positive and negative contact electrodes (3, 4, 5, 6); the positive and negative contact electrodes pass through The conductive welding strip 7 is connected, and the insulating adhesive film 8 is used to isolate and insulate between the conductive welding strip 7 and the block positive and negative grid line electrodes (5, 6).

Embodiment 2

[0025] Example 2, in the staggered back contact IBC solar cell electrode structure described in Example 1: the positive and negative grid electrodes (1, 2) are segmented electrodes that do not penetrate the entire surface of the cell.

Embodiment 3

[0026] Embodiment 3, in the staggered back contact IBC solar cell electrode structure described in Embodiment 1: the adjacent cells are rotated by 180°, and the positive and negative contact electrodes of the two cells are on a straight line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com