Detector for detecting liquid crystal module

A detection device and liquid crystal module technology, which is applied to the casing of the measuring device, the device for joining/disconnecting the connecting parts, optics, etc. In exchange for the module to be tested, it is convenient, the fixture height is minimized, and the production efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

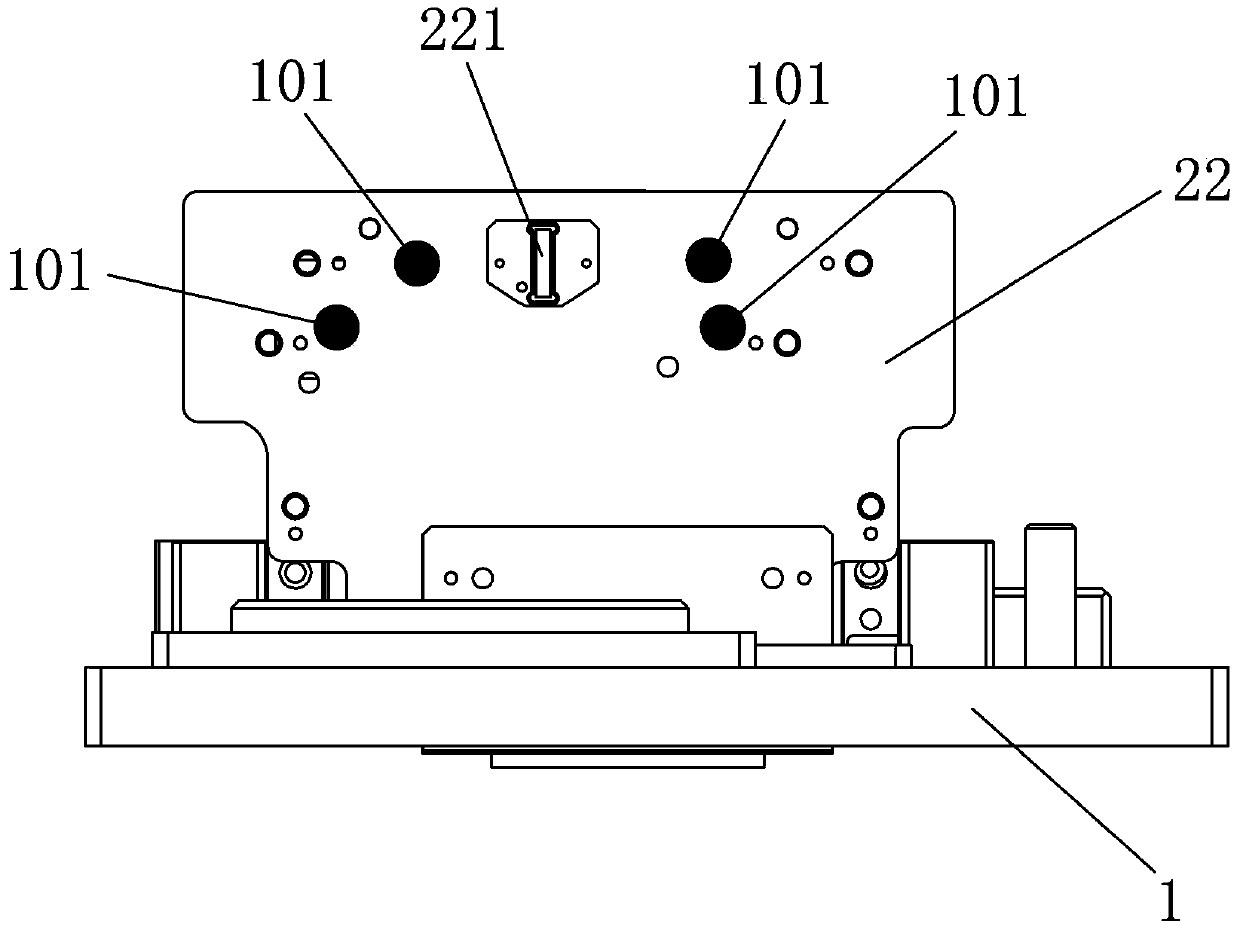

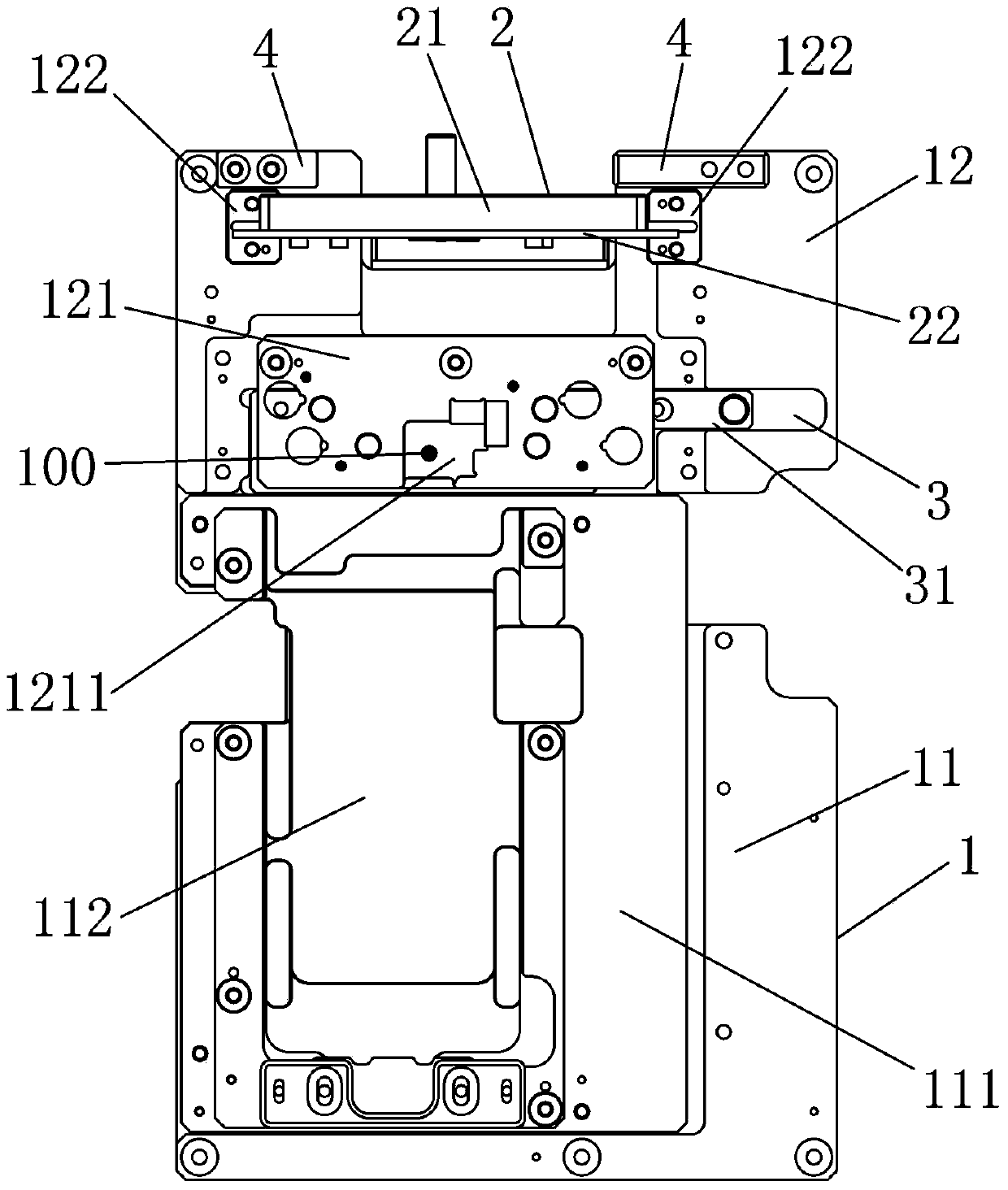

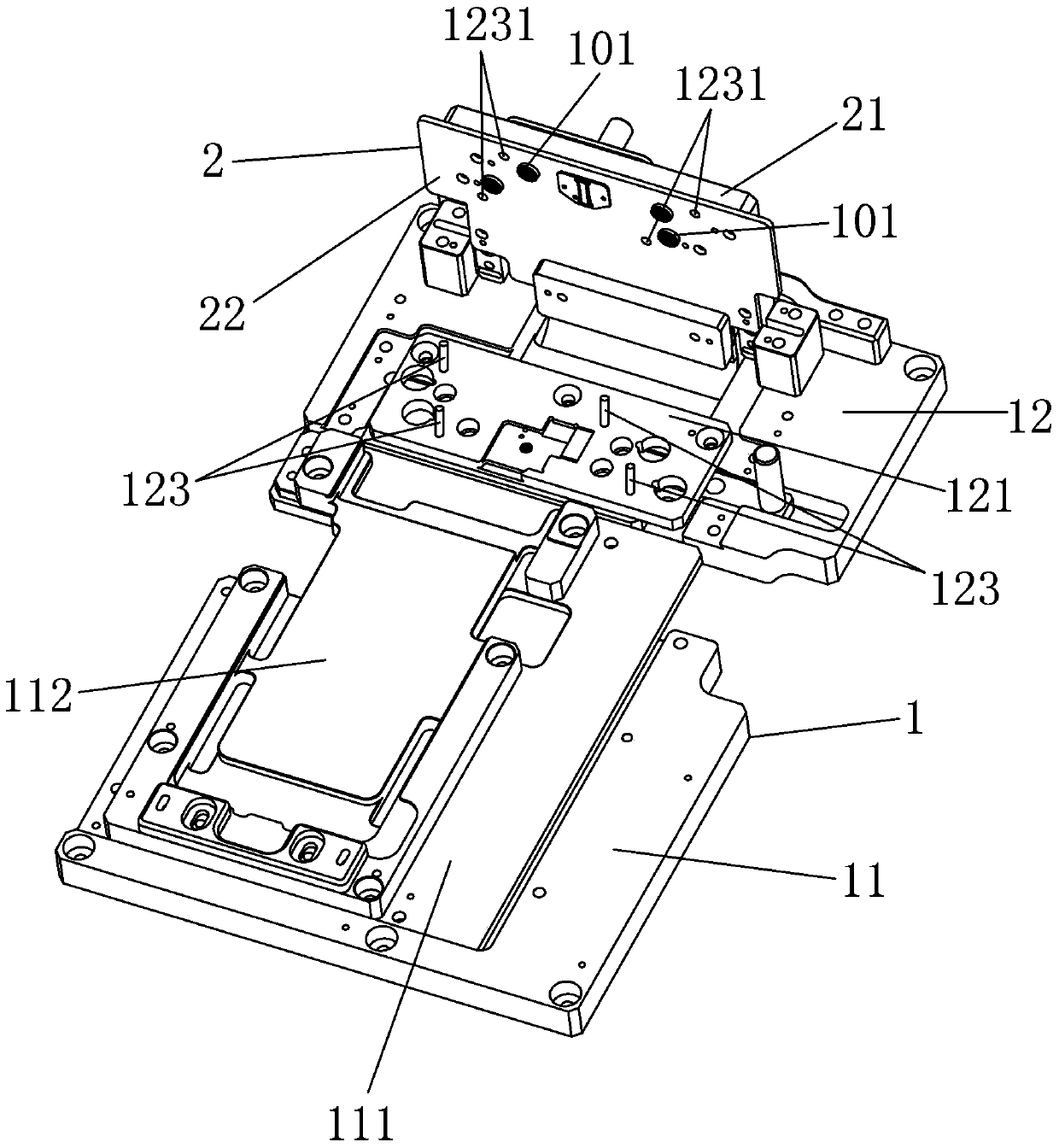

[0081] Such as Figures 1 to 23 As shown, a detection device for liquid crystal module detection, the detection device includes a top plate 1 and a flip assembly 2; the top plate 1 includes a first top plate 11 and a second plate 12; the first A backing plate 111 affixed to the first top plate 11 and a module supporting plate 112 affixed to the backing plate 111 are sequentially arranged on the top plate 11, and the module to be tested is placed on the mold. Group pallet 112.

[0082] The plate surface of the second second plate 12 is fixed with a limiting plate 121, which is provided with a cavity 1211 for placing the connector port of the module to be tested; the limiting plate 121 is used for positioning the module to be tested. Set the connector port to control the mating height of the connector detection port on the detection substrate and the connector port of the module to be tested. The cavity 1211 is provided with a first magnet 100 for fixing the connector port of ...

Embodiment 2

[0102] The difference between this embodiment and Embodiment 1 is that: the turnover assembly includes a substrate fixing plate, and a first detection substrate and a second detection substrate are arranged on the inner side of the substrate fixing plate; The two detection substrates are respectively provided with connector detection ports.

[0103] The limit plate is respectively provided with a cavity for placing the connector port of the module to be tested that matches the position of the connector detection port on the first detection substrate; Cavities for placing the connector ports of the module under test that match the position of the test port.

Embodiment 3

[0105] The difference between this embodiment and Embodiment 1 is that: the substrate fixing plate is rotatably connected to the second plate through a hinge; crimp together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com