A kind of biosynthesis method of t-2 toxin

A biosynthesis, T-2 technology, applied in the field of biosynthesis of T-2 toxin, can solve the problems of strong reagent toxicity, high cost, cumbersome and complicated treatment, etc., achieve simple sample processing method, reduce toxin cost, and simplify process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The recovery of embodiment 1 bacterial classification and the preparation of conidia liquid

[0025] Preparation of Potato Dextrose Agar Medium (also known as PDA Medium): Commercially available potatoes were washed with distilled water, peeled, and cut into 3 cm long and wide pieces with a knife. Take 200g of potato pieces, put them into a 1L beaker, add 400mL of distilled water, boil for 10min, filter with gauze, discard the potato pieces, keep the filtrate, add 20g of glucose; 20g of agar; after heating to dissolve, add distilled water to 1000mL. Sterilize under high-pressure steam at 121°C for 20 minutes for use, heat and dissolve in a microwave oven before use, pour the plate on an ultra-clean operating table, and seal it with a parafilm after cooling for use.

[0026] Preparation of conidia suspension medium (also known as CMC medium): Each 1 LCMC medium contains 7.5g sodium carboxymethylcellulose, 0.5g potassium dihydrogen phosphate, 0.5g yeast powder, 0.5g ammon...

Embodiment 2

[0030] Embodiment 2 toxin-producing cultivation and yield monitoring

[0031] Inoculation culture of corn toxin-producing medium: After 7 days of culture in a desktop refrigerated constant temperature shaker, take the CMC conidia culture medium cultured on a shaker, scrape off the conidia carefully with an inoculation loop in an ultra-clean bench, and mix to form a suspension , take the sterilized pipette tip with a pipette holster, carefully draw 2mL of conidia suspension in the aseptic area of the alcohol lamp and add it to 90 sterilized conical flasks packed with corn, seal with a parafilm tight. After the inoculation is completed, place the Erlenmeyer flask in a sterilized mold incubator, away from light. The culture temperature was set at 15°C and the humidity was 50%. Shake the Erlenmeyer flask evenly every day to ensure sufficient oxygen and uniform distribution of toxins, and promote the production of toxins. On the 11th day, 16th day, 21st day and 28th day of cul...

Embodiment 3

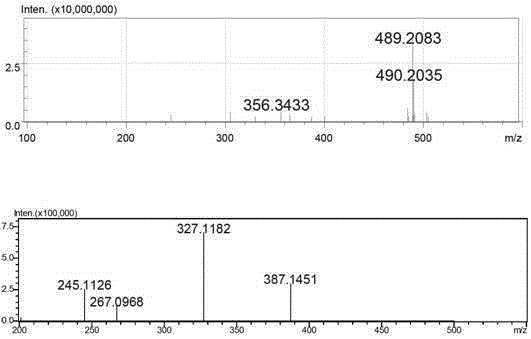

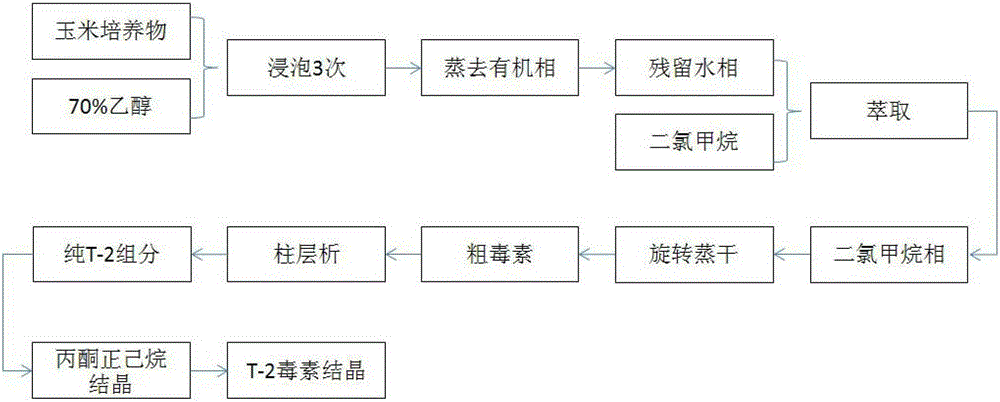

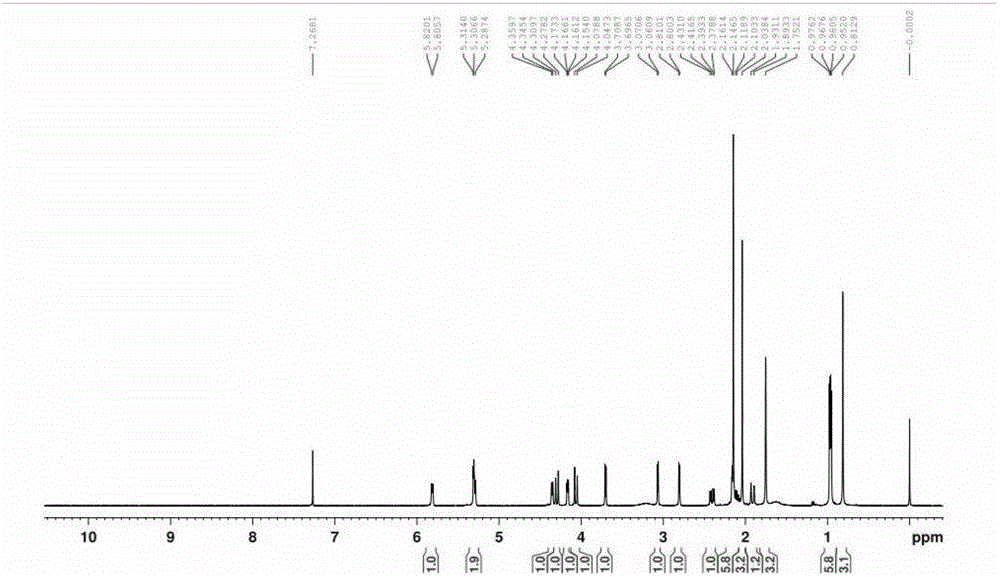

[0037] The separation and purification of embodiment 3T-2 toxin

[0038] After 28 days of inoculation and cultivation of the corn toxin-producing medium, the medium was taken out from the mold incubator, and the corn was carefully dried overnight in a drying oven. The next day, each 100g of corn culture was stirred and soaked overnight with 400mL of 70% ethanol, extracted three times, and the 70% ethanol extract was recovered by suction filtration. After the filtrate is collected, adjust the water temperature of the rotary evaporator to 65 degrees Celsius, rotate each 1L of ethanol extract to about 100mL-300mL at 40-60℃ on the rotary evaporator, and collect the water phase. Shake the remaining turbid aqueous phase to mix the precipitate. Add it to a 2L separatory funnel, add dichloromethane according to the water phase: dichloromethane 2:1 (v / v), shake evenly, and let it stand until it slowly separates. The dichloromethane phase was collected, and the aqueous phase was repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com