Joint mixture

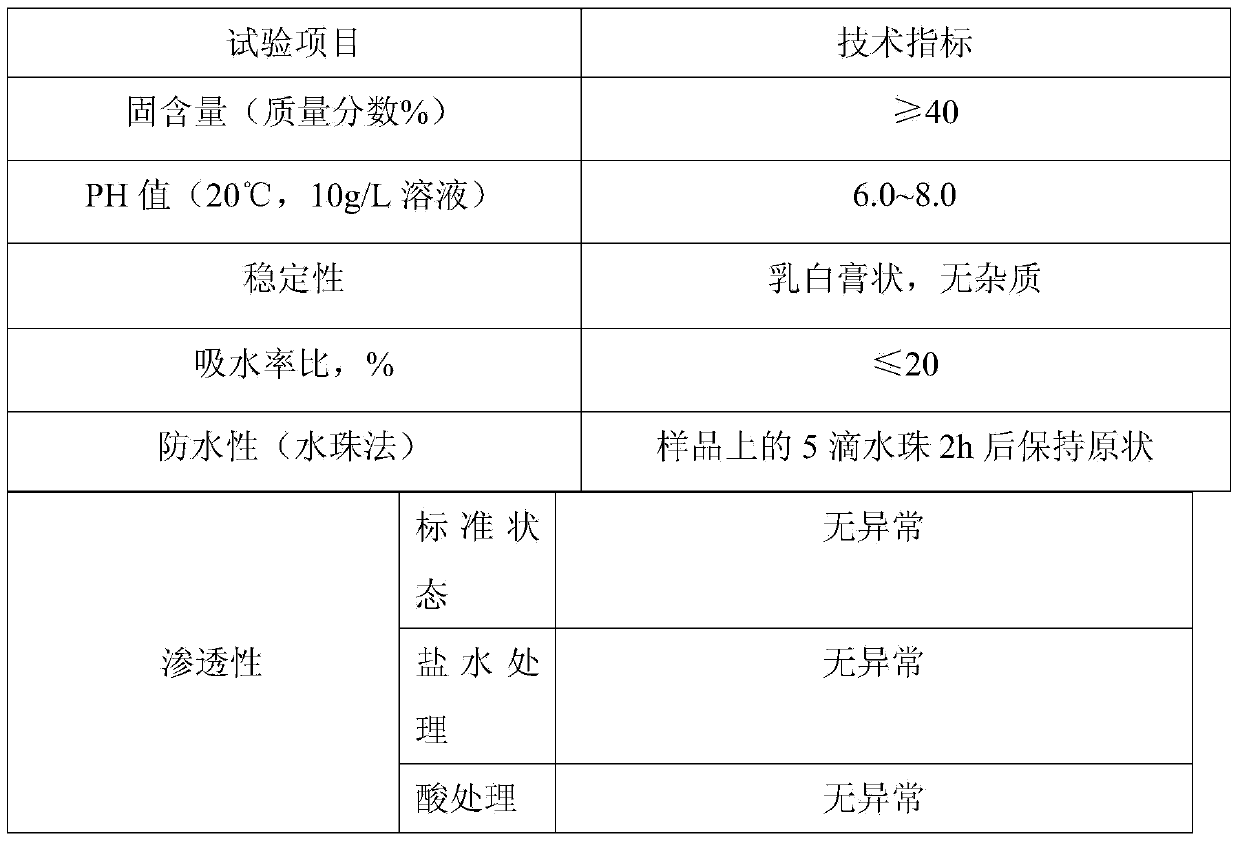

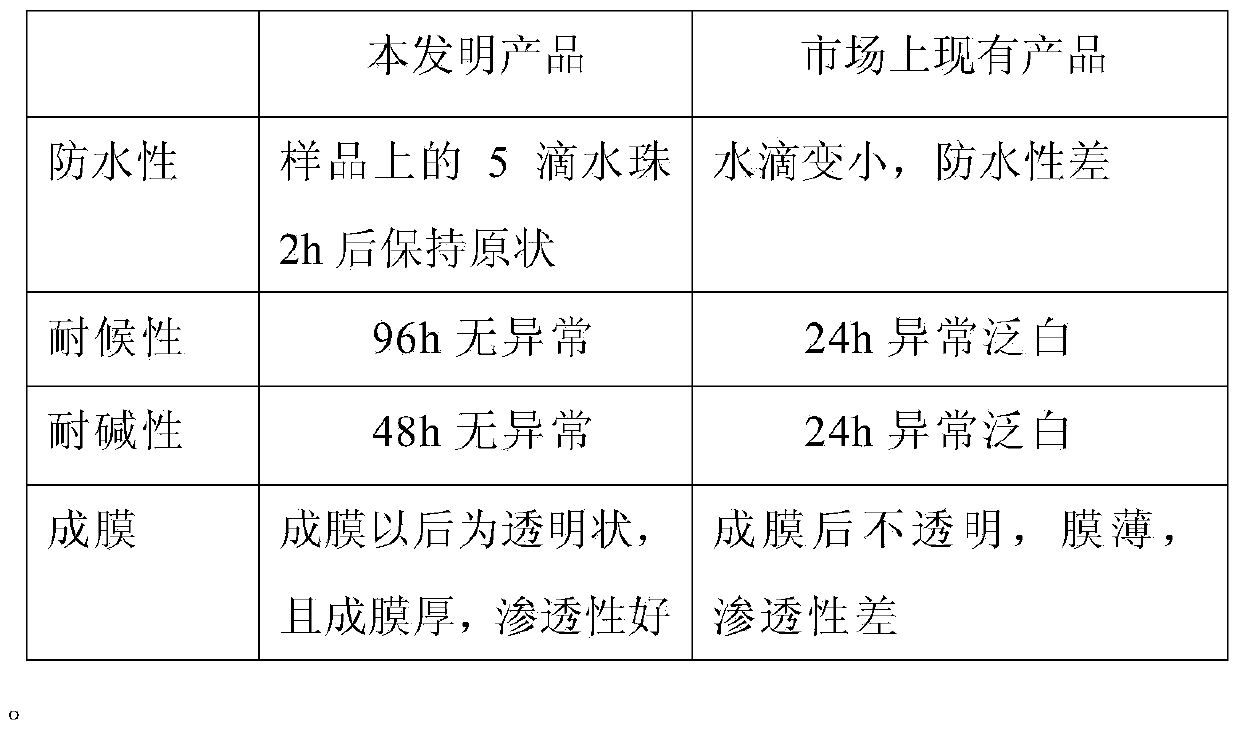

A technology of caulking agent and thickening agent, applied in the field of caulking agent, can solve the problems of low solid content, thin film, opacity, etc., achieve high solid content, good anti-seepage performance, strong weather resistance and alkali resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A caulking agent, which is prepared by mixing and stirring the following components in parts by weight: 500 parts of silicone emulsion, 500 parts of acrylic emulsion, 2 parts of bactericide, 1 part of defoamer and 20 parts of thickener. The solid content of above-mentioned acrylic emulsion is 52%.

[0019] In this embodiment, the silicone emulsion is a cationic hydroxy silicone oil emulsion, wherein the silicone emulsion has a silicon content of 10% by mass and a solid content of 50%, and the thickener is a polyacrylic acid salt alkali swelling type For the emulsion, the solid content of the thickener is 20%, and the defoamer is polysiloxane.

[0020] The preparation method of the above-mentioned caulking agent is as follows: mix and stir the required amount of each component material, stir for 2 hours, and the stirring speed is 500r / min to obtain the desired product.

Embodiment 2

[0022] A caulking agent is prepared by mixing and stirring the following components in parts by weight: 400 parts of silicone emulsion, 600 parts of acrylic emulsion, 1 part of bactericide, 2 parts of defoamer and 15 parts of thickener. The solid content of the acrylic emulsion is 53%

[0023] In this embodiment, the silicone emulsion is a cationic hydroxy silicone oil emulsion, wherein the silicone emulsion has a silicon content of 15% by mass and a solid content of 52%, and the thickener is a polyacrylic acid salt alkali swelling type Emulsion, the solid content of the thickener is 25%, and the defoamer is a polyacrylic acid polymer.

[0024] The preparation method of the above-mentioned caulking agent is as follows: mixing and stirring the required amount of each component material, stirring for 1.5 hours, and the stirring speed is 700r / min to obtain the desired product.

Embodiment 3

[0026] A caulking agent, which consists of the following components in parts by weight: 600 parts of silicone emulsion, 400 parts of acrylic emulsion, 1.5 parts of bactericide, 1.5 parts of defoamer and 10 parts of thickener mixed and stirred, wherein, the The solid content of above-mentioned acrylic emulsion is 55%.

[0027] In this embodiment, the silicone emulsion is a cationic hydroxyl silicone oil emulsion, wherein the silicone emulsion has a silicon content of 20% by mass and a solid content of 52%, and the thickener is a polyacrylic acid salt-alkali swelling type Emulsion, the solid content of the thickener is 25%, and the defoamer is a mixture of polysiloxane and polyacrylic acid polymer,

[0028] The preparation method of the above-mentioned caulking agent is as follows: mixing and stirring the required amount of each component material, stirring for 1 hour, and the stirring speed is 800r / min to obtain the desired product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com