Mopping cloth with high dust collection effect

A ground cloth and floor technology, which is applied to cleaning carpets, floors, household appliances, etc., can solve the problems of limited ability to hold dust, cost, and affect work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

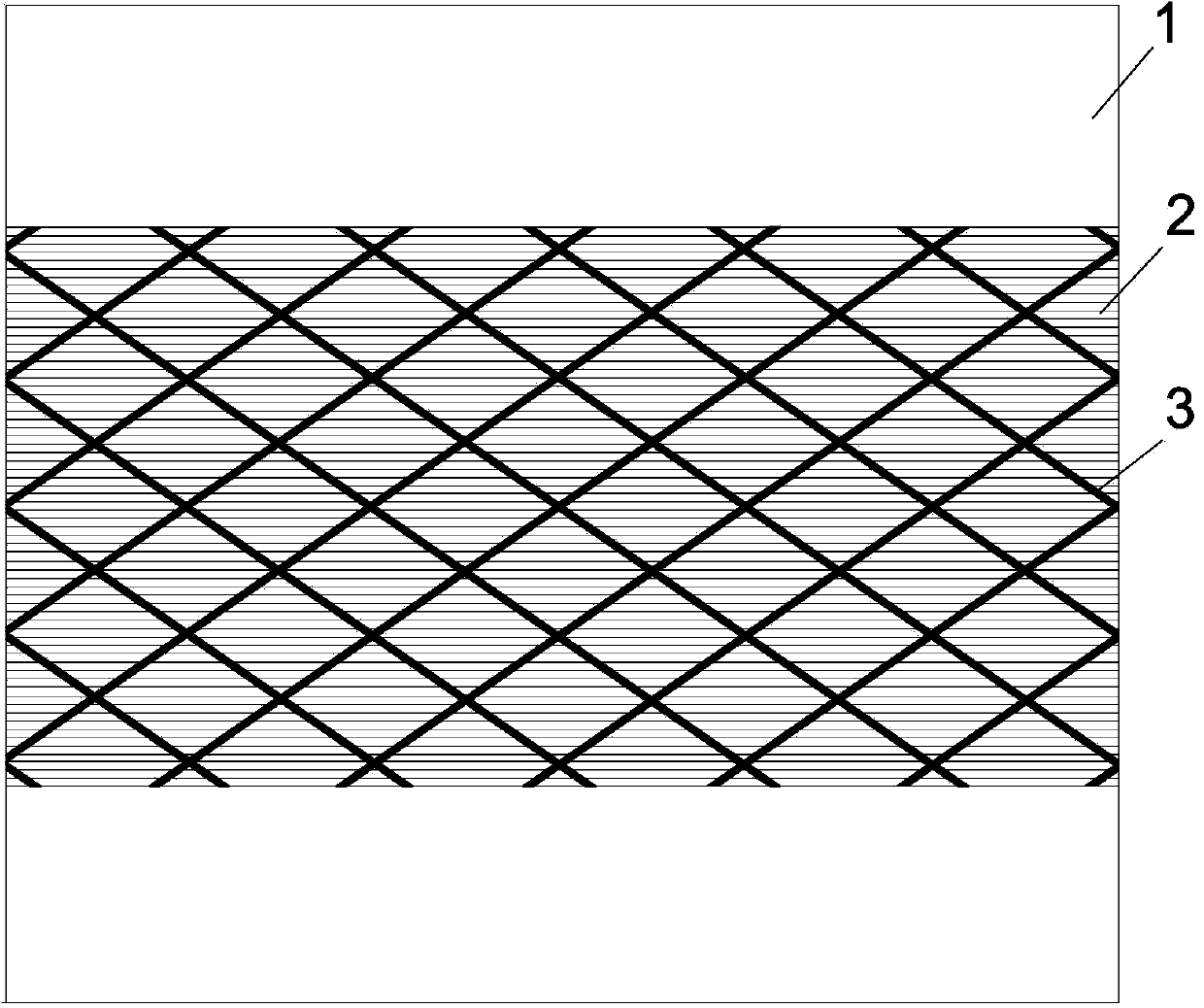

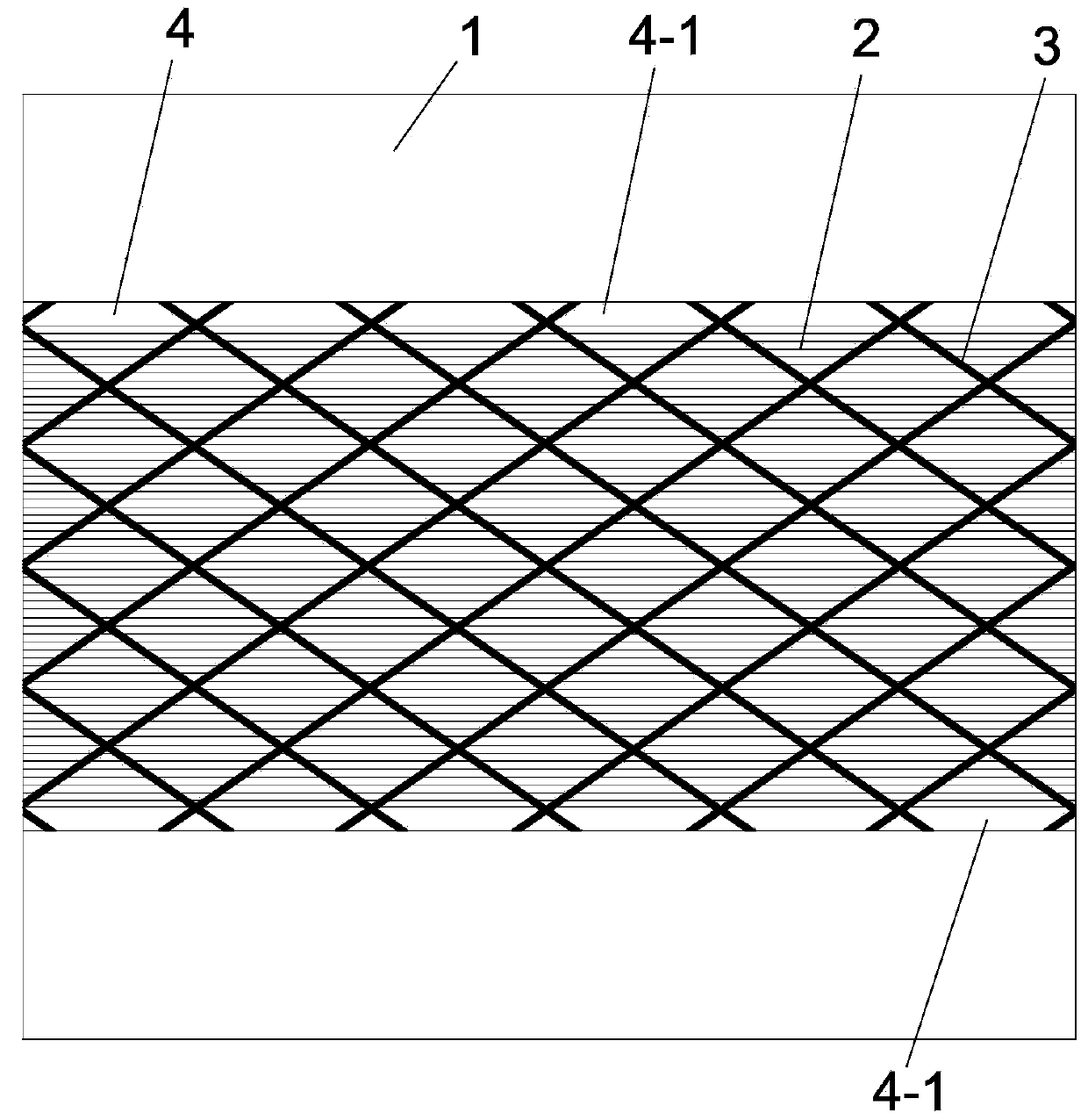

[0024] As shown in the figure, the mopping cloth with high cleaning effect provided by the present invention has a bottom layer of non-woven fabric 1, and a chemical fiber layer 2 is fixed on the non-woven fabric. welding machine for hot-melt welding), the chemical fiber layer and the non-woven fabric are heated together to a molten state, and several hot-melt welding lines 3 are formed after cooling, and the chemical fiber layer and the non-woven fabric are fixed as a whole. All of the above are similar to the existing mopping cloth.

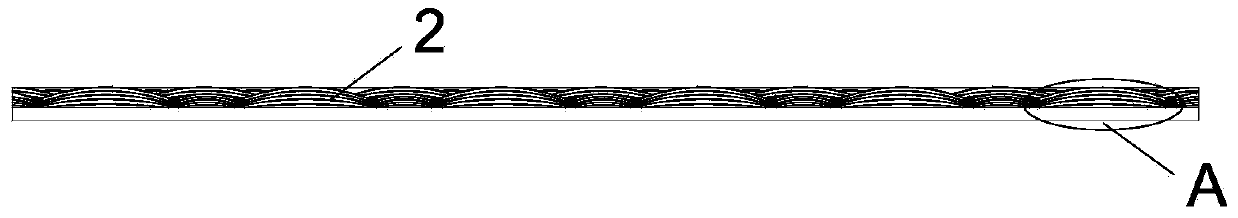

[0025] The innovation of the present invention is: the chemical fiber layer is a chemical ultrafine fiber layer (the thickness of the chemical ultrafine fiber layer is determined according to needs); all ultrafine chemical fibers in the chemical ultrafine fiber layer are all along the mop cloth. length direction (i.e. figure 1 , image 3 The left and right directions) are stretched, and after being connected with the non-woven fabric through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com