Safety door device of injection moulding machine

An injection molding machine, safety door technology, applied in the field of safety door devices, can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

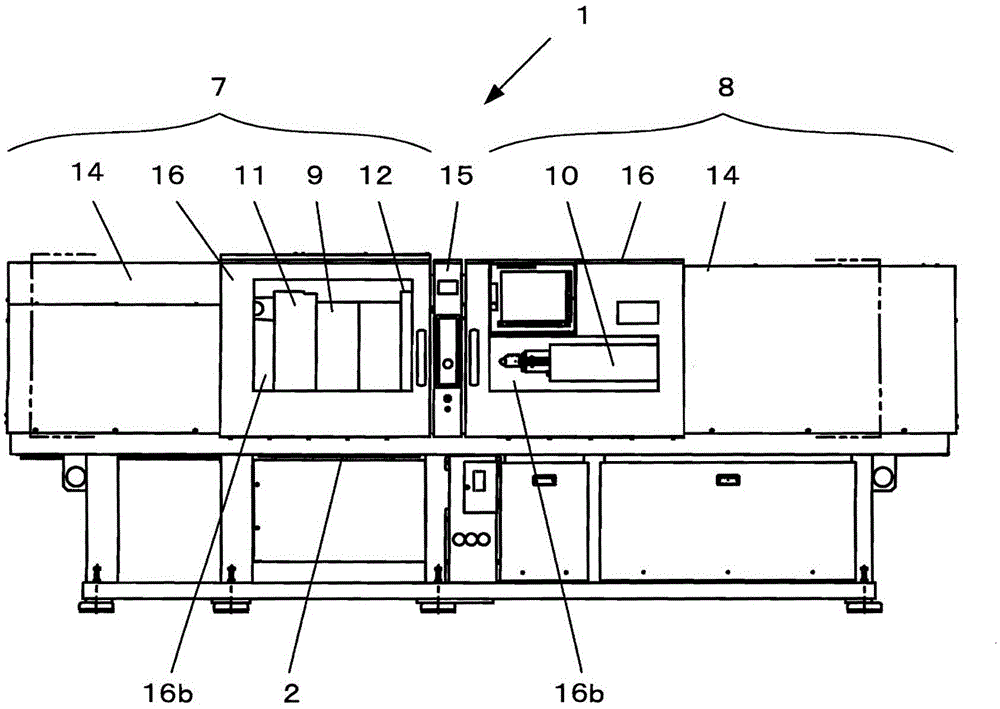

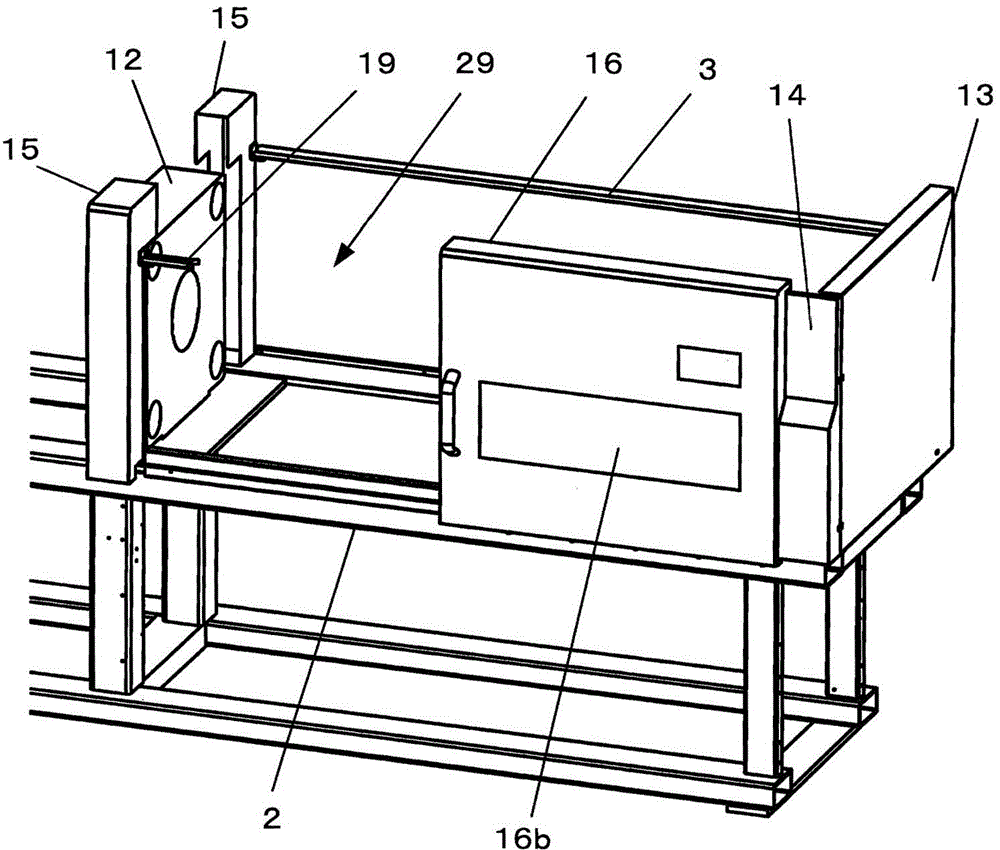

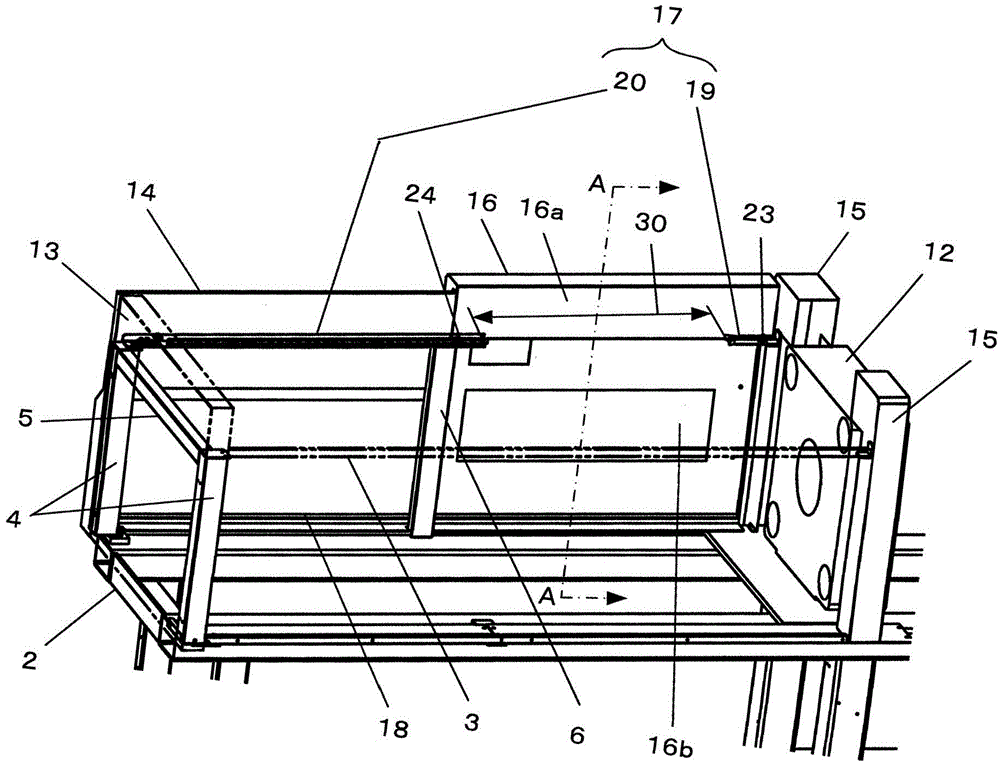

[0031] use figure 1 An injection molding machine equipped with the safety door device of the present invention will be described.

[0032] The injection molding machine 1 is composed of a mold clamping unit 7 and an injection unit 8 . The clamping part 7 and the injection part 8 are arranged opposite to each other on the machine base, and each has a plurality of mechanical driving parts, and the movement of each part is strong and high-speed, which may bring danger to the operator, so the fixing of the end parts Cover 13 (refer to figure 2), the fixed cover 14 on the side and other covers, so as to isolate it from the workers. In addition, reference numeral 15 denotes a fixed shelf cover covering the fixed shelf 12 .

[0033] In the replacement of the mold 9, the replacement of the cylinder part 10, etc., it is necessary to provide the clamping space (between the movable shelf 11 and the fixed shelf 12) of the mold clamping part 7, and the space for the rotation axis (bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com