Coarse coal slime sorting machine

A sorting machine and coarse coal slime technology, applied in the field of coal mine machinery and equipment, can solve the problems of affecting sorting effect, local accumulation of materials, increasing process cost, etc., so as to improve sorting effect, improve dispersion effect, and reduce construction costs. Effects of cost and production process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

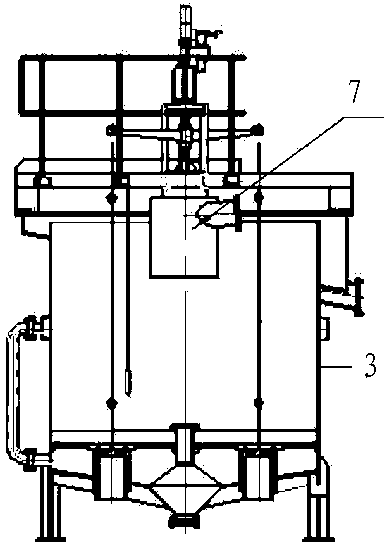

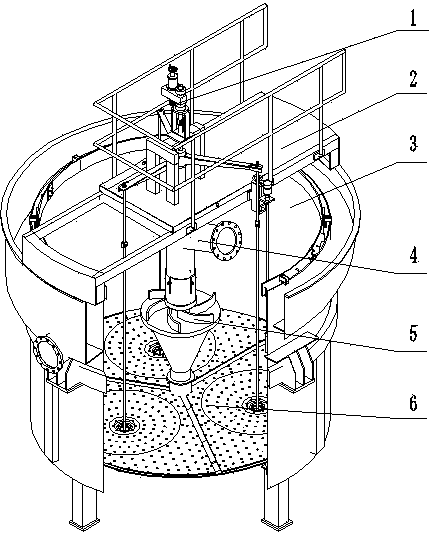

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes an electric actuator 1, an observation platform 2, a cylinder body 3, an adjustable feeding device 4, a swirl interference device 5, a water tank 6, and the like. Among them, the electric actuator 1 is installed on the top of the observation platform 2, and the observation platform 2 is seated on the top of the cylinder body 3. The flange above the adjustable feeding device 4 is connected to the observation platform 2, and the lower end is connected with the swirl interference device 5, and the swirl interference Device 5 is installed in the water tank 6 and is preferably its upper center position.

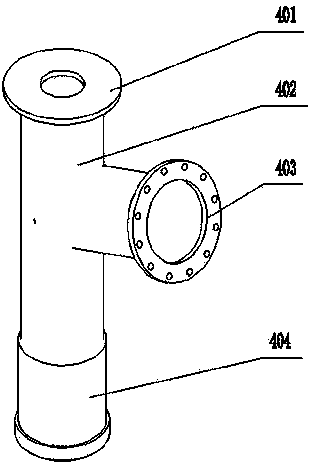

[0019] The adjustable feeding device 4 includes a connection flange 401, a material inlet flange 402, a three-way pipe 403, a movable sleeve 404, and the like. Wherein the connecting flange 401 is connected with the observation platform 2, the material inlet flange 402 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com