Anti-torsion and environment-resistant ultra-flexible cable for field photography

A field photography, environment-resistant technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of rapid loss, disorder, cracking, etc., to improve the mechanical strength of insulation, prolong the service life, and increase the tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

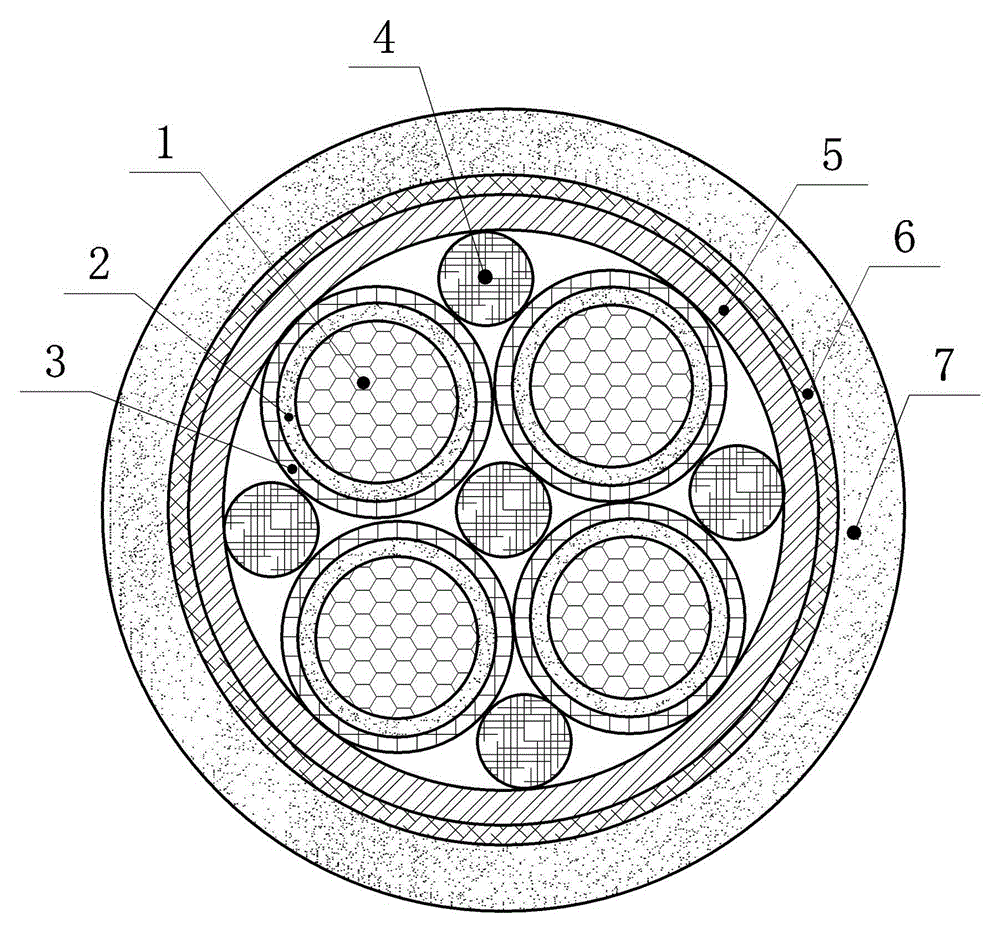

[0024] Example: see figure 1 , a torsion-resistant and environment-resistant ultra-flexible cable for field photography, consisting of multiple insulated cores and a buffer protection outer layer, the buffer protection outer layer is wrapped around the multiple insulated cores, and is arranged between the multiple insulated cores There are reinforcing ribs 4; the insulated wire core includes a soft conductor 1, an insulating layer 2 and an aromatic hydrocarbon braid 3, and the buffer protection outer layer sequentially includes a cabled tape layer 5, a steel wire braid 6 and an outer sheath from inside to outside Layer 7.

[0025] Among them: the soft conductor 1 is made of multiple strands of fine oxygen-free copper wires, which are processed by the process of bundle first and then twist; the insulation layer 2 is made of vulcanization-free ethylene-propylene rubber elastomer with high tensile strength, good flexibility, and fatigue crack resistance Composite extruded; aroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com