Round tube combination buffering device

A buffer device and circular tube technology, applied in the direction of elastic shock absorbers, etc., can solve the problems of large load fluctuations, unstable buffer force, and low ratio, and achieve low cost, stable impact force, and average load/peak load ratio high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

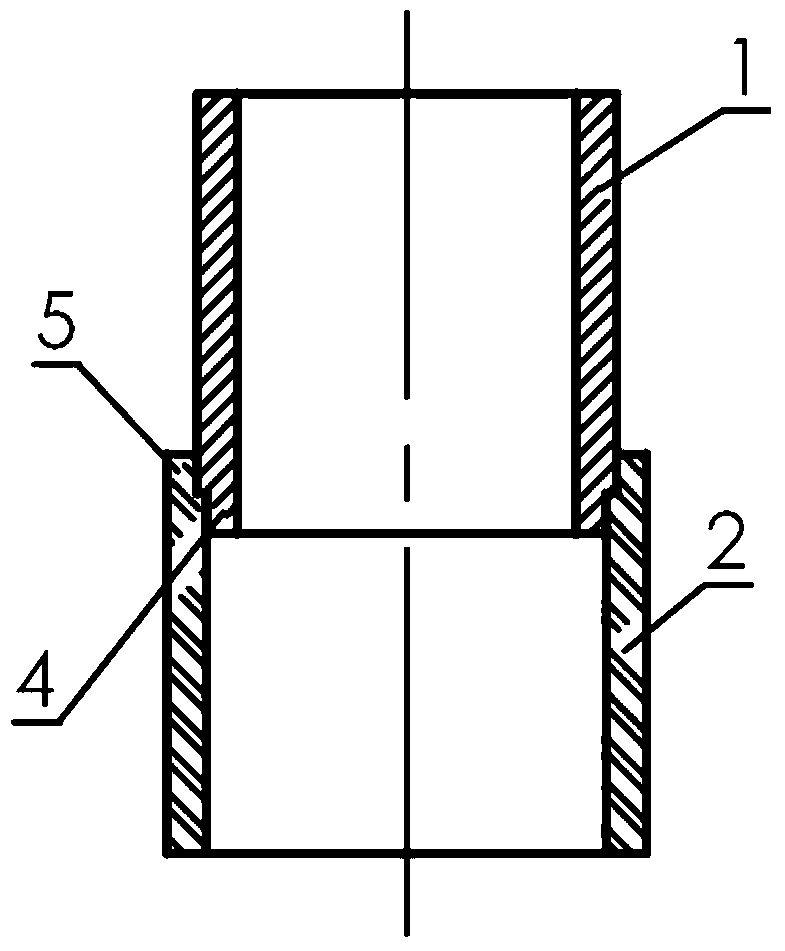

[0054] Example 1: Combining figure 1 Describe this embodiment, the buffer of this embodiment includes a small round tube 1 and a large round tube 2; the small round tube 1 is provided with a first boss 4, the large round tube 2 is provided with a second boss, the first boss 4 and the second The two bosses 5 are closely matched to realize the restraint and positioning of the small round tube 1 and the large round tube 2, and ensure that the round tube combined buffer device does not lose stability during deformation and energy absorption; the destructive strength of the small round tube 1 and the large round tube 2 is different, It is necessary to ensure that the higher-strength round pipe does not undergo plastic deformation during the shearing and extrusion deformation of the lower-strength round pipe, and the round pipe that undergoes shear deformation in the round-pipe combined buffer device is a plastic material.

Embodiment 2

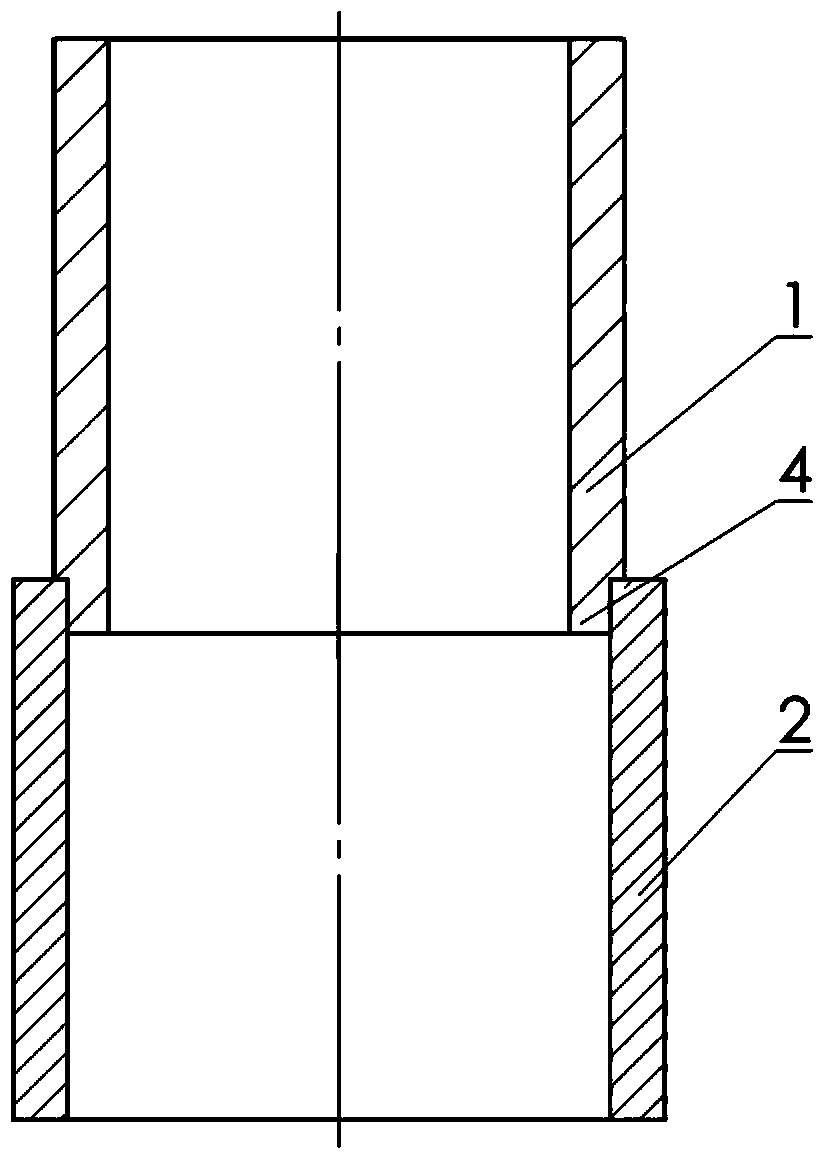

[0055] Example 2: Combining figure 1 and figure 2 Describe this embodiment, the buffer of this embodiment includes a small round tube 1 and a large round tube 2; The restraint and positioning of the large round tube 2 ensure that the round tube combined buffer device will not lose stability during deformation and energy absorption.

Embodiment 3

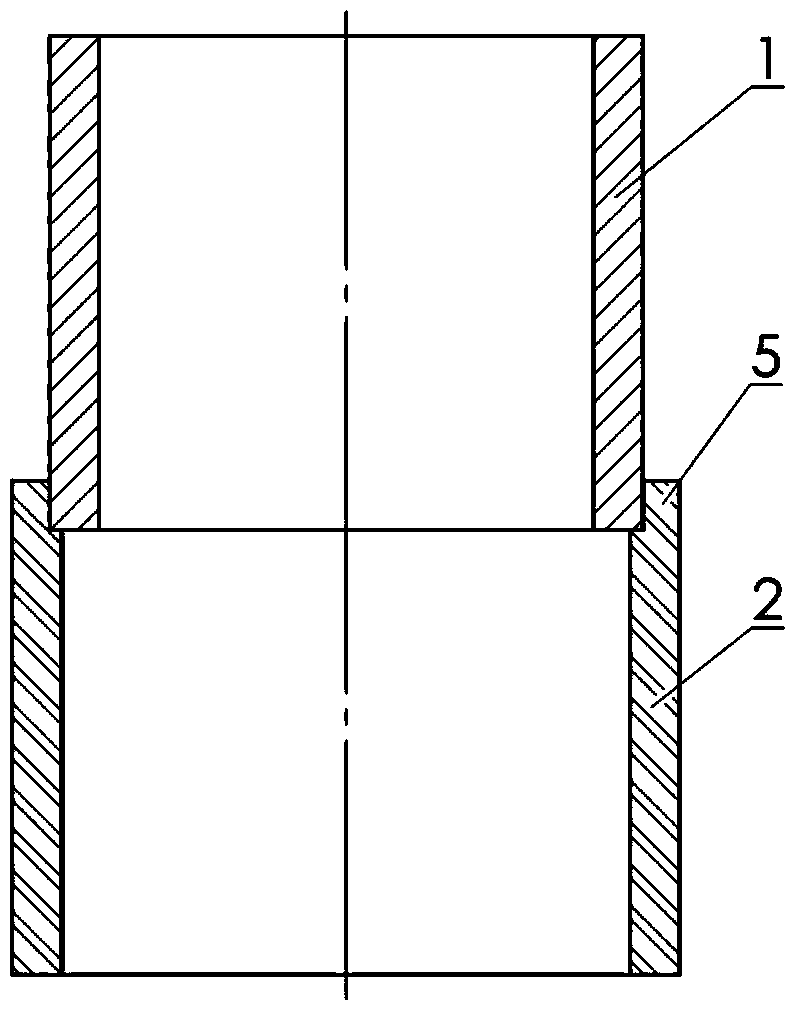

[0056] Example 3: Binding figure 1 and image 3 Describe this embodiment, the buffer of this embodiment includes a small round tube 1 and a large round tube 2; The restraint and positioning of the large round tube 2 ensure that the round tube combined buffer device will not lose stability during deformation and energy absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com