Piston type oil-less air compressor

An air compressor and piston type technology, applied in the field of compressors, can solve the problems of low efficiency, low efficiency and large volume of small air compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

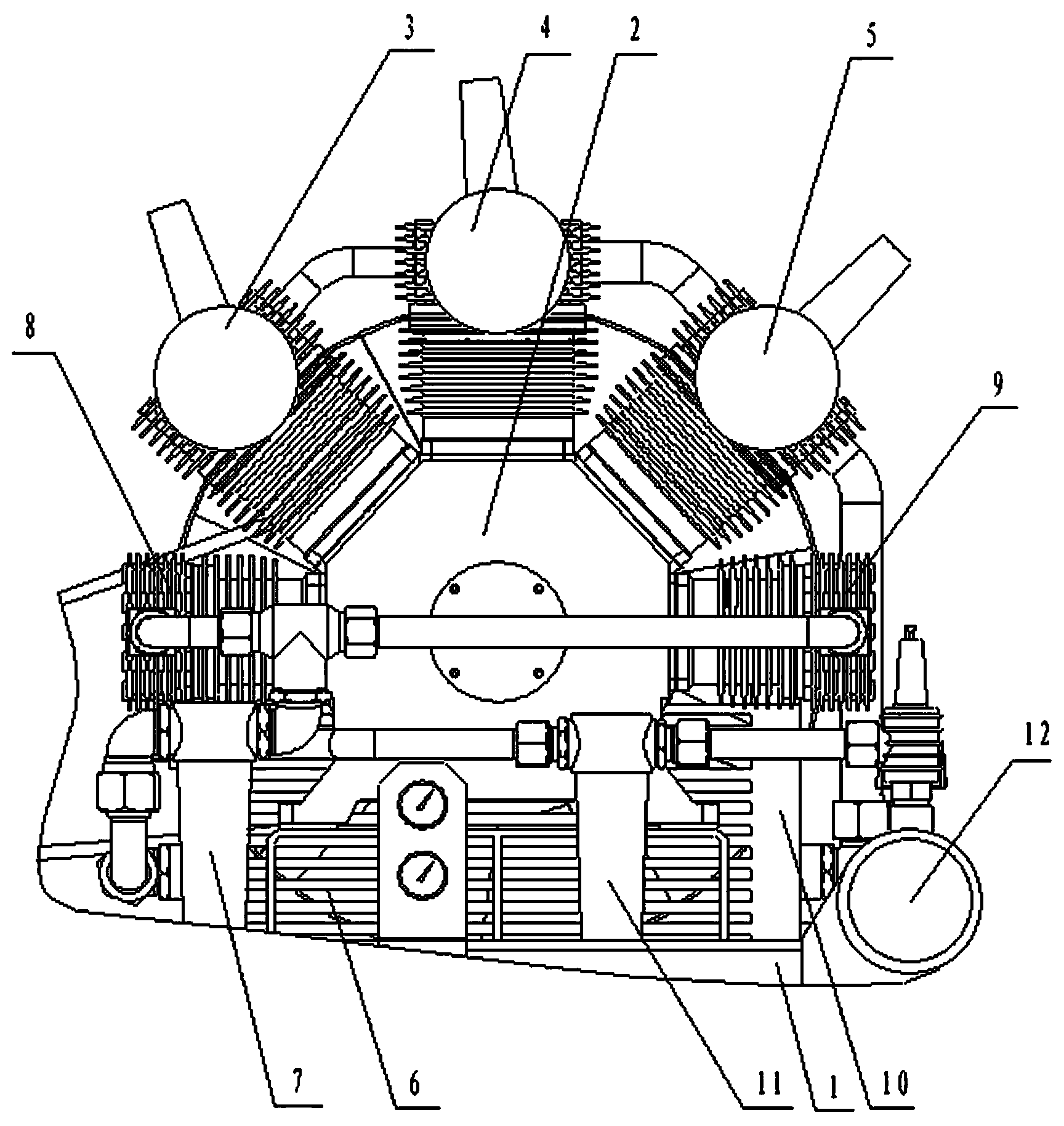

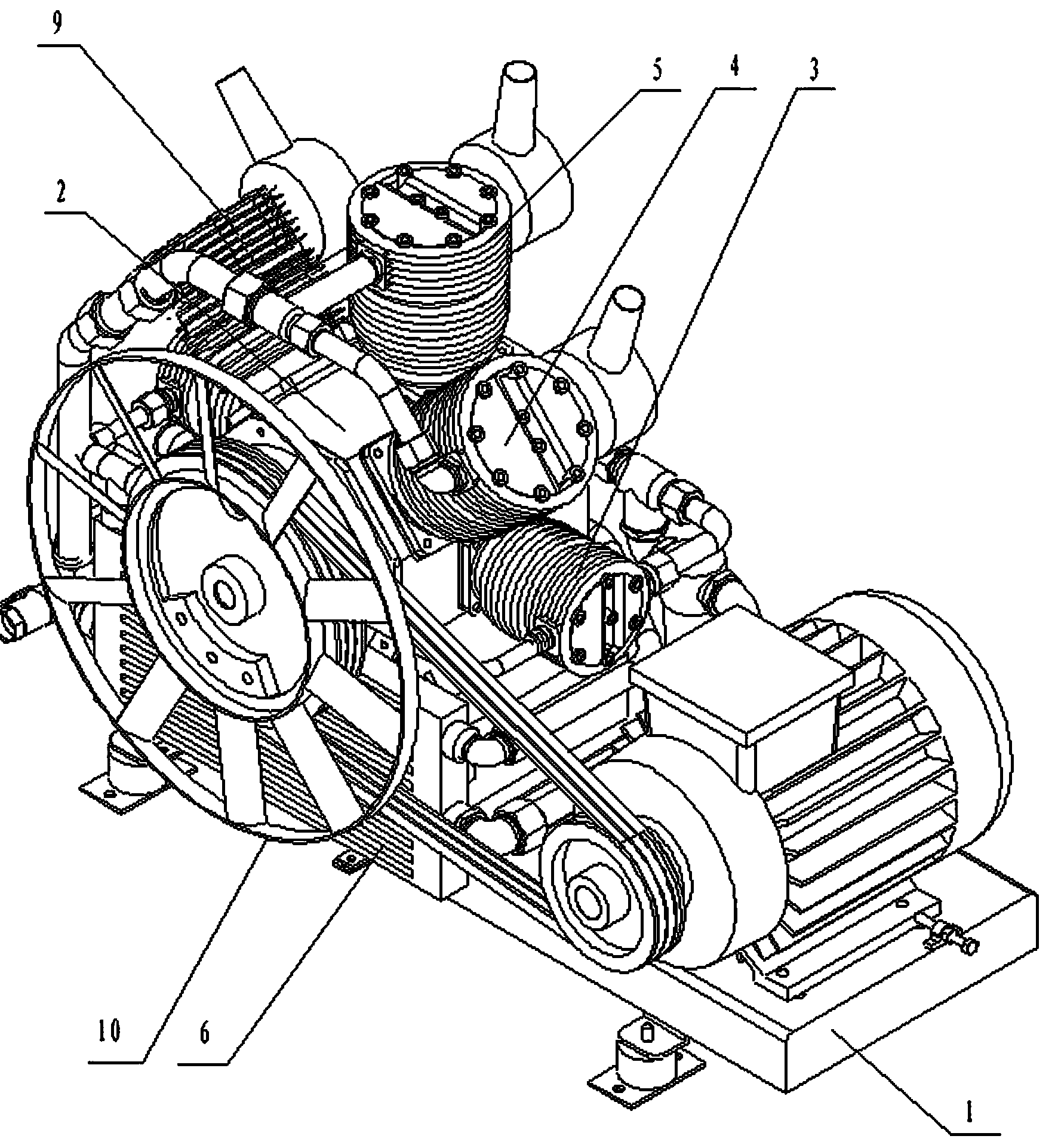

[0013] A piston type oil-free air compressor of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] This embodiment takes the application of the present invention / invention related to an air compressor on a SW-5.5 / 8-Q small oil-free air compressor with a volumetric flow rate of 5.5 cubic meters per minute and an exhaust pressure of 0.8 MPa as an example. Depend on figure 1 , figure 2 It can be seen that a piston type oil-free air compressor of the present embodiment is composed of a base 1, a crankcase 2 fixed on the base 1 by screws, a primary cylinder I3, a primary cylinder II4, a primary cylinder III5, Intercooler 6, primary air-water separator 7, secondary cylinder I8, secondary cylinder II9, aftercooler 10, secondary air-water separator 11 and gas storage tank 12 fixed on machine base 1; the middle One end of the cooler 6 is connected to the first-stage cylinder I3, the first-stage cylinder II4, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bore | aaaaa | aaaaa |

| Bore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com