Completely sealed circulating power generation system and power generation method for low-grade heat energy

A closed cycle, power generation system technology, applied in the fields of resources and environment, to avoid the increase of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

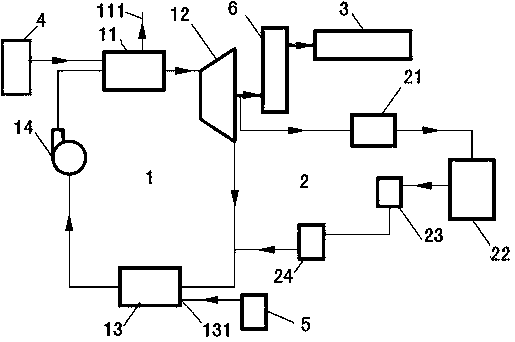

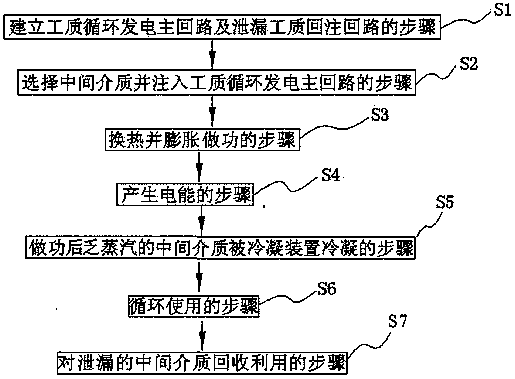

[0035] see figure 1 . The present invention is a completely closed cycle power generation system aimed at low-grade heat energy, which includes a working fluid circulation power generation main circuit 1 , a leakage working fluid reinjection circuit 2 , and a generator 3 .

[0036] The working fluid cycle power generation main circuit 1 is composed of an evaporating device 11, an expander 12, a condensing device 13, and a circulating pump 14; wherein: the evaporating device, the expanding machine, the condensing device, and the circulating pump are connected in sequence through pipelines , the output end of the circulating pump is connected to the working medium input end of the evaporating device through a pipeline to form a working medium circulation power generation main circuit. The low-grade heat energy input end of the evaporating device is connected to the low-grade heat energy output device 4, and low-grade heat energy is input to the evaporating device; the lower-gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com