Two-side-connection lateral-reinforcing and unequal-height vertical-gap forming steel plate shear wall

A steel plate shear wall, connecting side technology, applied in the direction of walls, building components, buildings, etc., to achieve excellent lateral stiffness and ultimate bearing capacity, easy to yield before buckling, to achieve the effect of energy dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

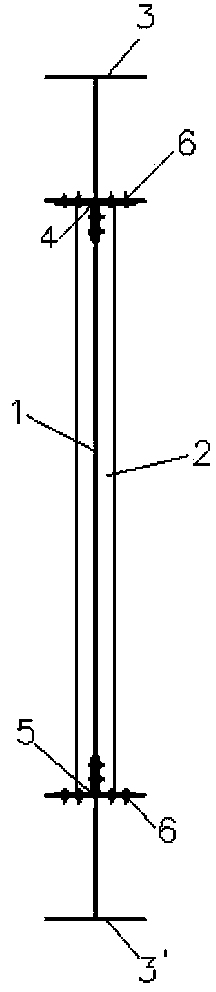

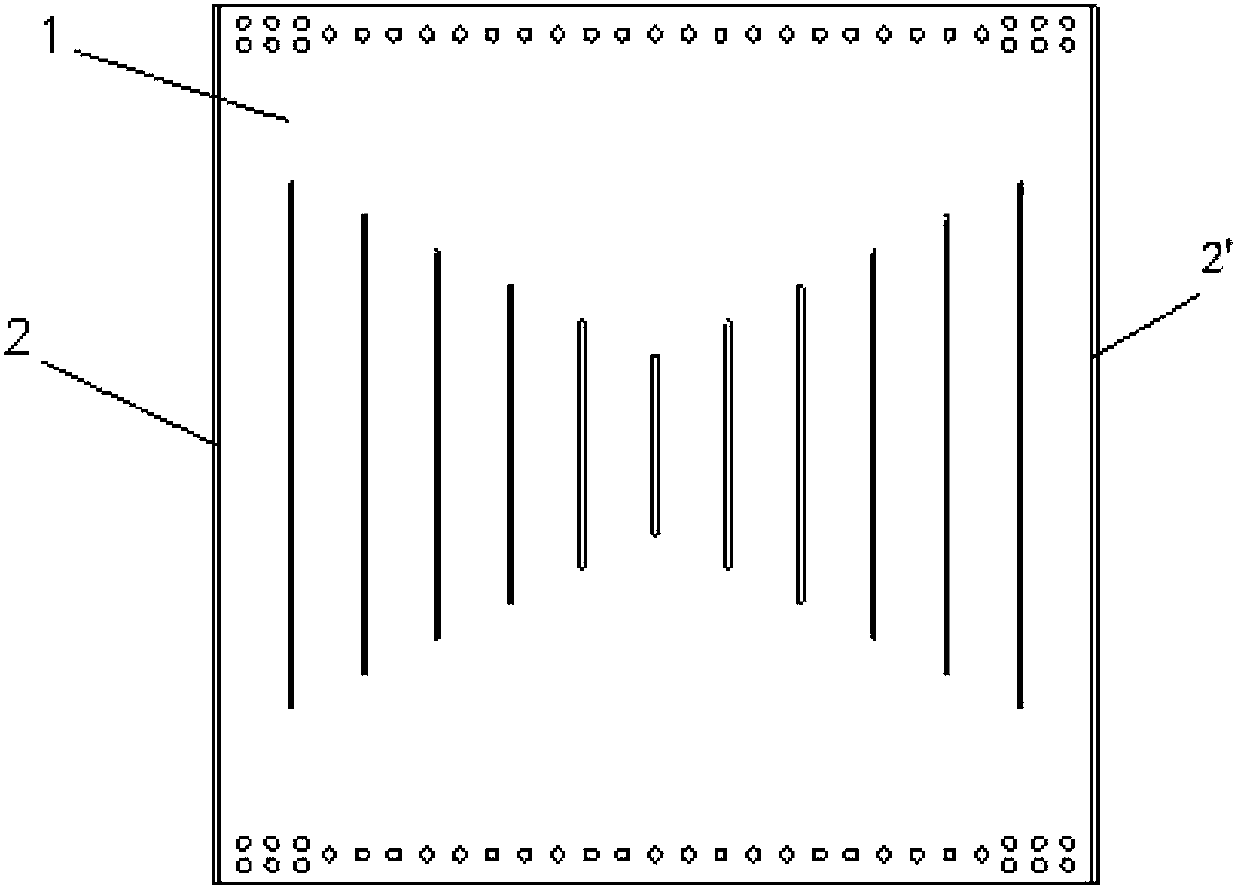

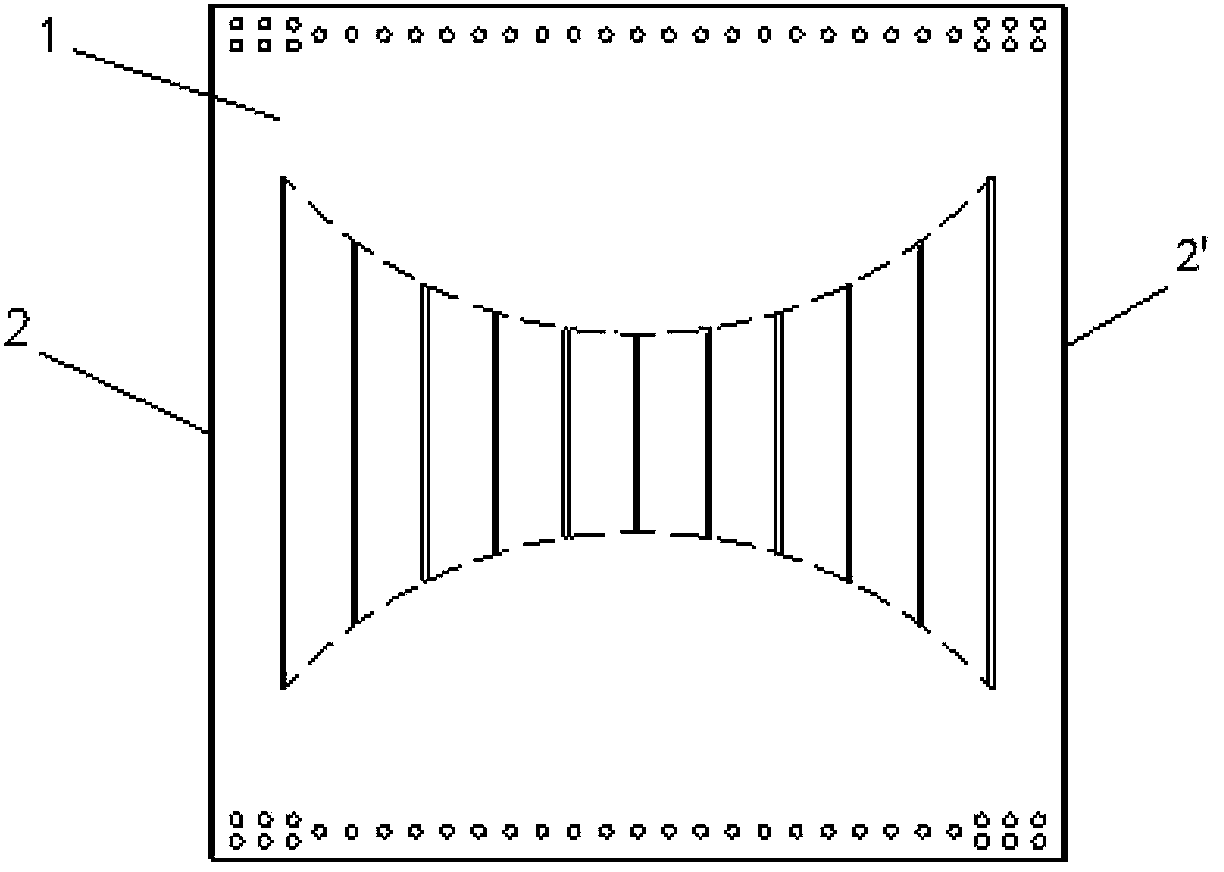

[0015] Such as figure 1 and figure 2 As shown, the steel plate shear wall with vertical seams at different heights connected on both sides of the present invention is composed of a steel plate with seams 1, an upper edge frame beam 3, a lower edge frame beam 3', an upper end angle steel 4 and a lower end angle steel 5; The seam steel plate 1, the upper edge frame beam 3, the lower edge frame beam 3', the upper end angle steel 4 and the lower end angle steel 5 are all equipped with screw bolts, such as Figure 6 As shown, more dense screw bolts are provided at the corners of the angle steel, and the upper end angle steel 4 and the lower end angle steel 5 are respectively connected to the upper edge frame beam 3 and the lower edge frame beam 3' through high-strength friction bolts. At the same time, both the upper angle steel 4 and the lower angle steel 5 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com