Drying, desulphurization and dehydration system and process for low-rank coal or coal slime

A desulfurization system, low-rank coal technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

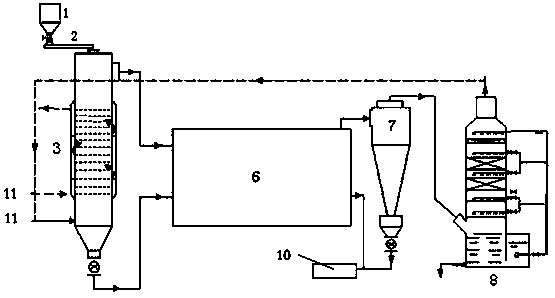

[0036] Example 1: Internal Heating Fluidized Bed Microwave Drying System

[0037] figure 1 Medium and low-rank coal or coal slime enter the internal heating fluidized bed dryer 3 from the silo 1 through the conveying device 2, and the discharge height of the feeding device is higher than the feeding port of the internal heating fluidized bed dryer 3; The air inlet of the built-in heat exchanger of the heating fluidized bed dryer 3 is connected with the superheated steam heat source, the air outlet of the inner heating fluidized bed dryer 3 is connected with the air inlet of the microwave dryer 6, and the discharge of the inner heating fluidized bed dryer 3 The mouth is connected with the feed port of the microwave dryer 6; the air outlet of the microwave dryer 6 is connected with the dust removal device 7 and the desulfurization device 8 in turn, and the desulfurization device 8 is also connected with the elemental sulfur recovery device; the outlet of the microwave dryer 6 is...

Embodiment 2

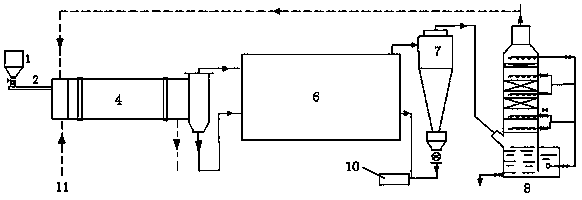

[0038] Embodiment 2: rotary cylinder microwave drying system

[0039] figure 2 Medium and low-rank coal or coal slime enter the rotary drum dryer 4 from the silo 1 through the conveying device 2, and the discharge height of the feeding device is higher than the feeding port of the rotary drum dryer 4; the rotary drum dryer 4 The air inlet of the built-in heat exchanger is connected to the superheated steam heat source, the air outlet of the rotary drum dryer 4 is connected to the air inlet of the microwave dryer 6, and the outlet of the rotary drum dryer 4 is connected to the inlet of the microwave dryer 6 Connection; 6 air outlets of the microwave dryer are connected with the dedusting device 7 and the desulfurization device 8 in turn, and the desulfurization device 8 is also connected with the elemental sulfur recovery device; connect.

Embodiment 3

[0040] Embodiment 3: airflow microwave drying system

[0041] image 3 Medium and low-rank coal or coal slime enter the airflow dryer 5 from the silo 1 through the conveying device 2, and the discharge height of the feeding device is higher than the inlet of the airflow dryer 5; The steam heat source is connected, the air outlet of the airflow dryer 5 is connected with the air inlet of the microwave dryer 6, the discharge port of the airflow dryer 5 is connected with the inlet of the microwave dryer 6; the air outlet of the microwave dryer 6 is connected with the dust removal device 7, desulfurization The devices 8 are connected in sequence, and the desulfurization device 8 is also connected with the elemental sulfur recovery device; the discharge port of the microwave dryer 6 and the discharge port of the dust removal device 7 are connected with the dry storage bin 10 respectively.

[0042] The low-rank coal or coal slime drying dehydration and desulfurization process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com