Internally dying method for diammonium phosphate

A technology of diammonium phosphate and dyeing method, applied in the directions of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., can solve the problems of secondary environmental pollution, large amount of colorant and high coloring cost, and achieves low cost, Significant effects of improving soil structure and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

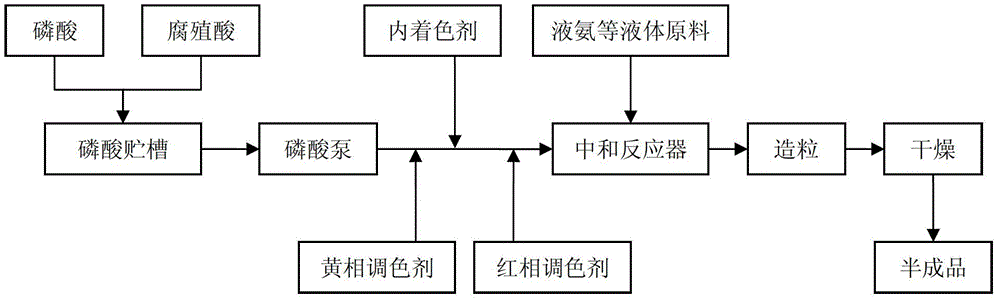

Method used

Image

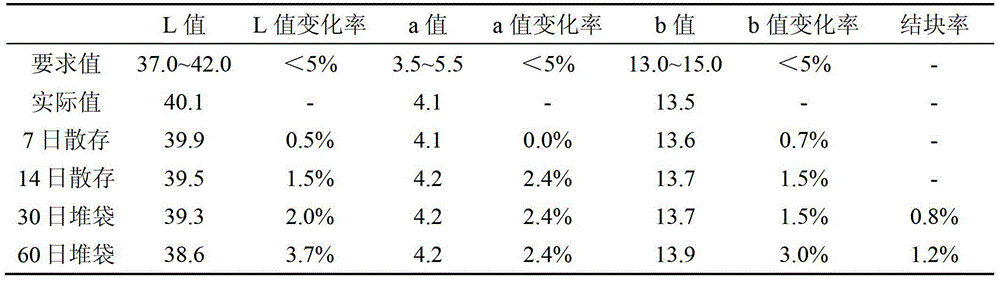

Examples

Embodiment 1

[0018] The internal dyeing method of embodiment 1, diammonium phosphate

[0019] Add the measured amount of humic acid into the phosphoric acid storage tank, and disperse it through the stirring paddle in the phosphoric acid storage tank for more than 2 hours. Phosphoric acid in the phosphoric acid storage tank enters the phosphoric acid feed pump through the discharge port, and the amount of humic acid added is controlled as follows: 1 mass part of humic acid is required to prepare 1000 mass parts of diammonium phosphate, and the water-soluble Sexual internal coloring agent (the internal coloring agent for black fertilizer provided by Wuxi COSCO Chemical Co., Ltd., which is composed of methylamine red, hydroxyethyl cellulose, polyvinyl alcohol and water, and their mass ratio is 12:5:2: 75), enter the inlet pipeline of the phosphoric acid feed pump through a screw pump with variable frequency speed regulation (the pump has a metering function, and the ratio of the flow rate to...

Embodiment 2

[0025] Add the measured amount of humic acid into the phosphoric acid storage tank, and disperse it through the stirring paddle in the phosphoric acid storage tank for more than 2 hours. Phosphoric acid in the phosphoric acid storage tank enters the phosphoric acid feed pump through the discharge port, and the amount of humic acid added is controlled as follows: 3 parts by mass of humic acid are required to prepare 1000 parts by mass of diammonium phosphate, and the water-soluble Sexual internal coloring agent (the internal coloring agent for black fertilizer provided by Wuxi COSCO Chemical Co., Ltd. is composed of methylamine red, hydroxyethyl cellulose, polyvinyl alcohol and water, and their mass ratio is 15:6:3:70 ), enter the inlet pipeline of the phosphoric acid feed pump through a screw pump with variable frequency speed regulation (the pump has a metering function, and the ratio of the flow rate to the phosphoric acid is controlled by DCS), wherein, the addition amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com