Puncture-preventing entry needle

An injection needle and anti-stab injury technology, applied in the field of injection needles, can solve the problems of complex injection needle structure, inability to popularize and use, and high manufacturing cost, and achieve the effects of significant social and economic benefits, easy popularization and application, and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

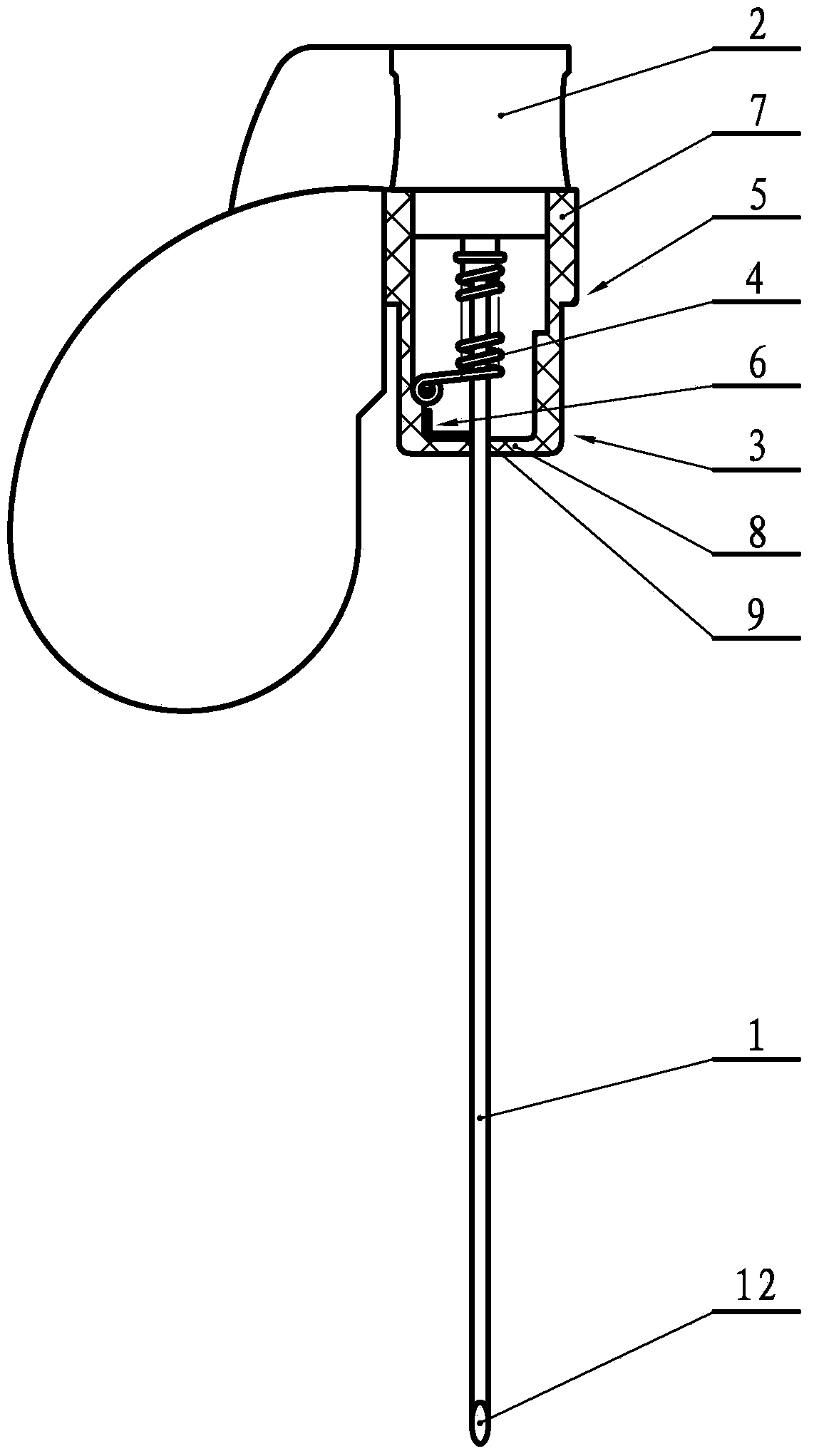

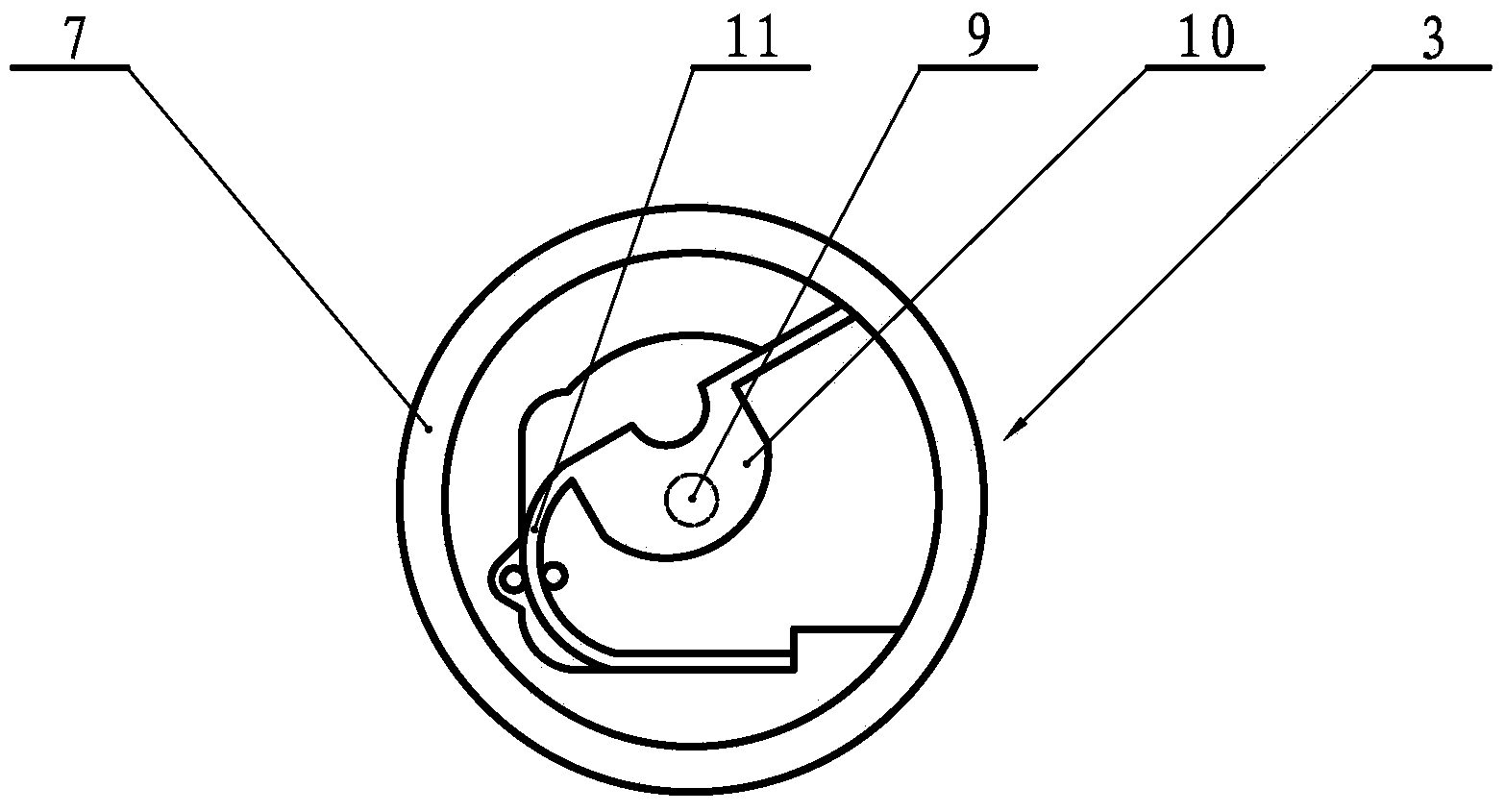

[0034] The structural representation of the anti-stab injection needle of the present invention is as follows: figure 1 and figure 2 As shown, it includes a needle body 1 and a needle seat 2, and a receiver 3 and a helical tension spring 4 are provided. The receiver 3 includes a casing 5 and a safety cap 6. The casing 5 includes a cylindrical wall 7 and an end plate 8. The cylindrical wall 7 is A cylindrical structure, one end of the cylindrical wall 7 is fixed with an end plate 8, the end plate 8 covers the central part of the cylindrical wall 7, the end plate 8 is located at the axial position of the cylindrical wall 7, and a pinhole 9 is set, and the pinhole 9 runs through the end plate 8, the shape and size of the pinhole 9 are compatible with the shape and size of the needle body 1, the inner side of the end plate 8 is provided with a safety cap 6, the safety cap 6 includes a baffle 10 and an elastic arm 11, and the baffle 10 is a plate One end of the elastic arm 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com