Production process for red tea

A production process, black tea technology, applied in tea treatment before extraction, etc., can solve the problems of long tea processing time and low production efficiency, shorten the time of withering and rolling, improve production efficiency, and have a mellow and refreshing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

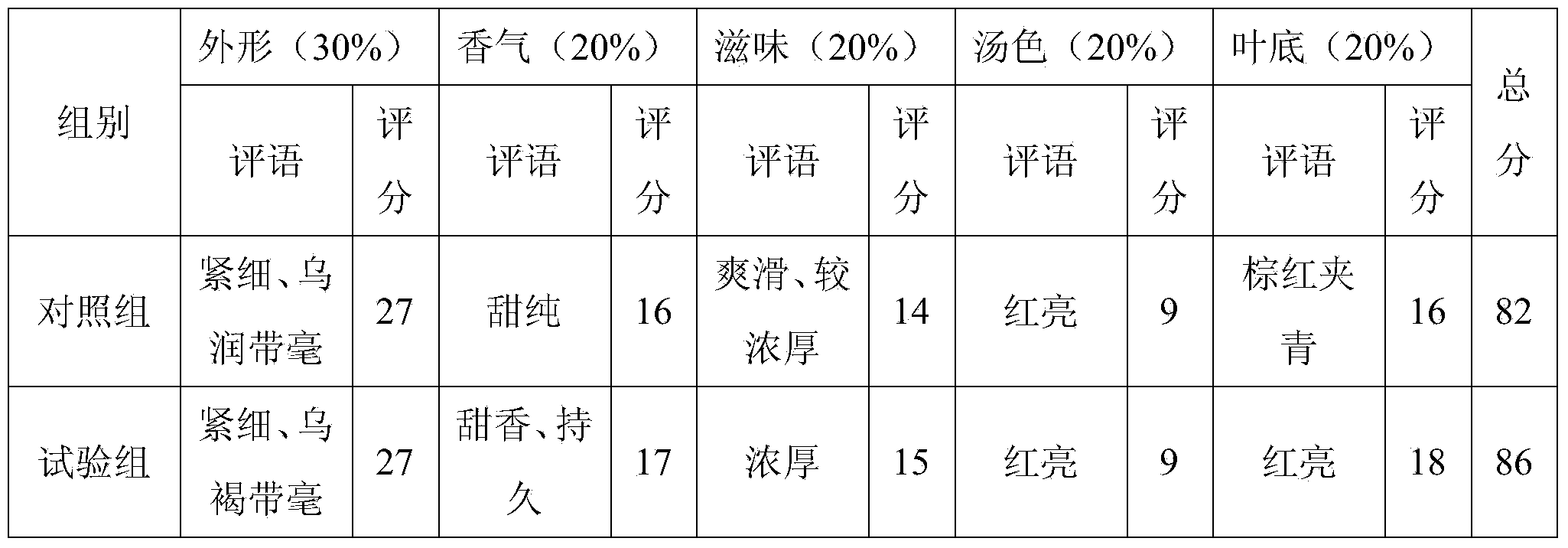

Examples

Embodiment 1

[0016] Spread the fresh leaves thinly, the leaf thickness is 1cm, the drying temperature is 22°C, the relative humidity is 55%, the drying time is 20min, and the leaves are turned twice when drying; shake the fresh leaves after drying, and put them on the shelf Dissipate heat, per 1m 2 Spread 1.0kg of fresh leaves, keep the room temperature at 20°C, and the relative humidity at 65%. Freeze the withered fresh leaves for 2 hours in a freezer at -10°C; spread the frozen leaves thinly at room temperature with a fan and blow them in order to avoid the formation of a large amount of condensation on the surface of the tea leaves, and thaw until the tea leaves become soft again. The tea leaves are kneaded by a rolling machine, and the kneading is pressed in the order of "light-heavy-light", with light pressure as the main method, and the time is 15 minutes until the tea leaves are rolled into strips; after the kneaded leaves are wrapped with wet gauze, they are placed in a bamboo siev...

Embodiment 2

[0018] Spread the fresh leaves thinly, the leaf thickness is 2cm, the drying temperature is 28°C, the relative humidity is 75%, the drying time is 60min, and the leaves are turned twice when drying; shake the fresh leaves after drying, and put them on the shelf Dissipate heat, per 1m 2 Spread 1.5kg of fresh leaves, keep the room temperature at 23°C, and the relative humidity at 75%. Freeze the withered fresh leaves in a freezer at -15°C for 3 hours; spread the frozen leaves thinly at room temperature with a fan and blow them in order to avoid the formation of a large amount of condensed water on the surface of the tea leaves, and thaw until the tea leaves become soft again. The tea leaves are kneaded with a rolling machine, and the kneading is pressed in the order of "light-heavy-light", with light pressure as the main method, and the time is 30 minutes until the tea leaves are formed into strips; after the kneaded leaves are wrapped with wet gauze, they are placed in a bamboo...

Embodiment 3

[0020] Spread the fresh leaves thinly, the leaf thickness is 1.5cm, the drying temperature is 25°C, the relative humidity is 65%, the drying time is 40min, and the leaves are turned twice when drying; shake the fresh leaves after drying, and put them on the shelf Dissipate heat from above, every 1m 2 Spread 1.2kg of fresh leaves, keep the room temperature at 22°C and 70% relative humidity. Freeze the withered fresh leaves in a freezer at -12°C for 2 hours; spread the frozen leaves thinly at room temperature with a fan and blow them in order to avoid the formation of a large amount of condensation on the surface of the tea leaves, and thaw until the tea leaves become soft again. The tea leaves are kneaded by a rolling machine, and the kneading is pressed in the order of "light-heavy-light", with light pressure as the main method, and the time is 20 minutes until the tea leaves are rolled into strips; after the kneaded leaves are wrapped with wet gauze, they are placed in a bamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com